Novel bidirectional paper board grooving machine

A slotting machine and cardboard technology, which is applied to paper/cardboard containers, papermaking, container manufacturing machinery, etc., can solve the problems of affecting slotting tools, short correction time of cardboard, affecting the quality of cardboard slotting, etc., and achieve high slotting accuracy. , Guaranteed durable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

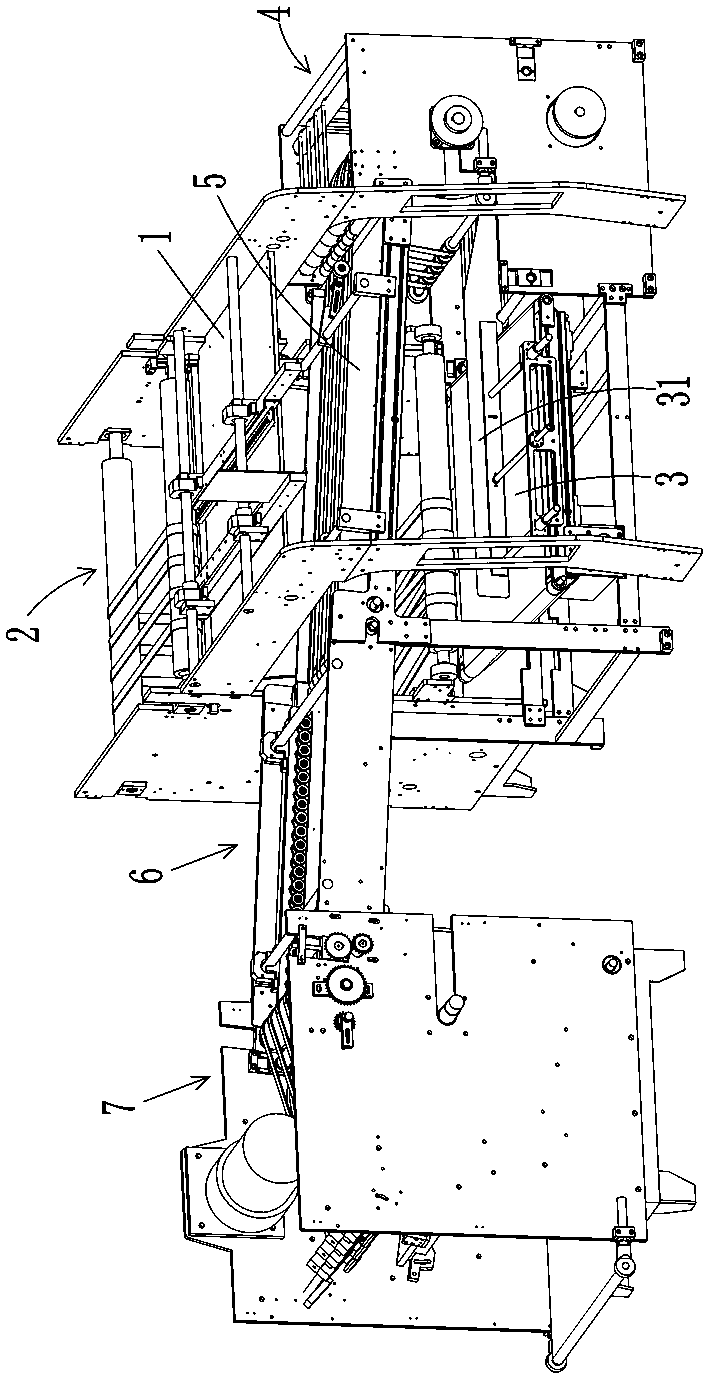

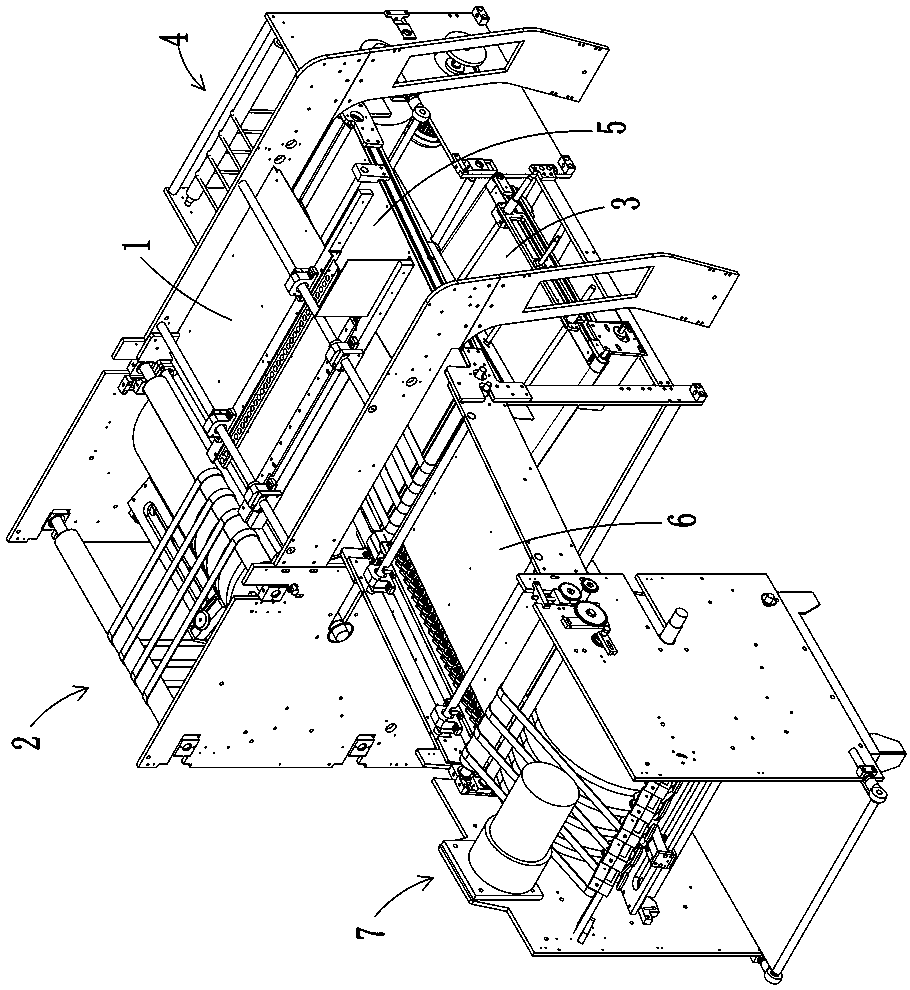

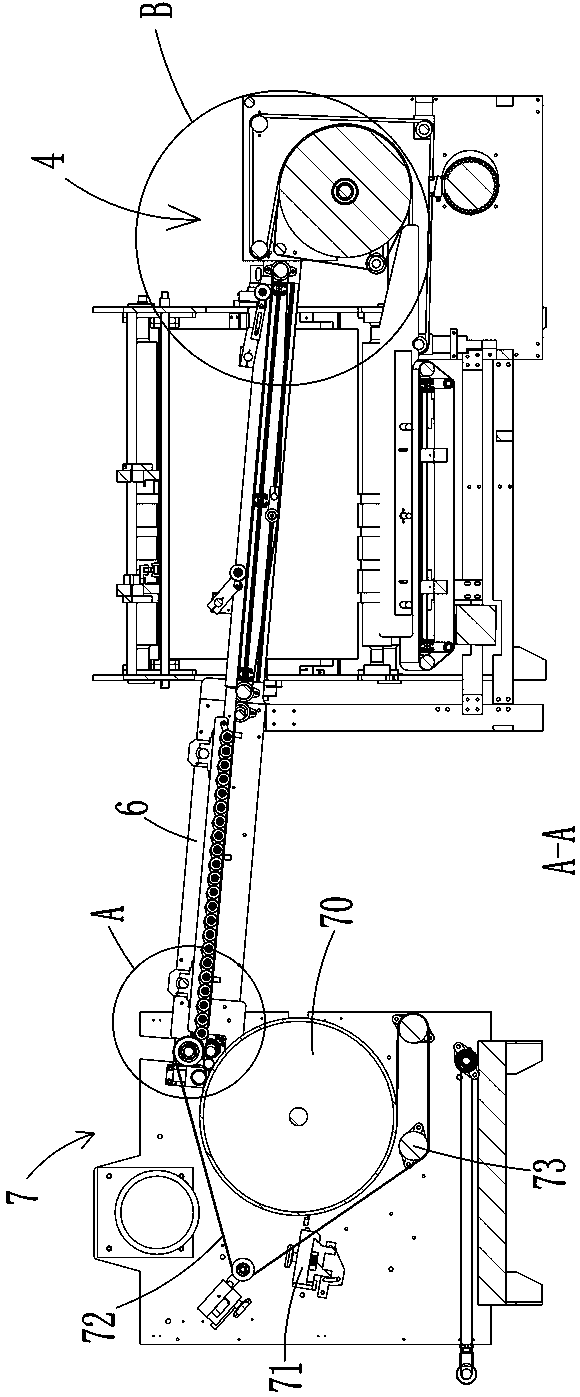

[0019] Such as Figure 1-3 As shown, this new type of two-way cardboard slotting machine includes a feeding mechanism 1, a primary slotting mechanism 2 and a secondary slotting mechanism 7, and the primary slotting mechanism 2 includes a slotting roller, a slotting knife and a belt. On the grooving roller, the cardboard is conveyed between the two, and the grooving knife longitudinally grooves the cardboard; the secondary grooving mechanism 7 also has the same structure and principle, but due to the different position settings, the secondary grooving Mechanism 7 performs horizontal slotting on the cardboard, and the "two-way" in the two-way cardboard slotting machine refers to the meaning of horizontal slotting and longitudinal slotting. The specific structures of both are prior art and will not be described in detail here.

[0020] The feeding end of the primary slotting mechanism 2 of the present invention is located at the upper end, the discharge end of the primary slotti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com