High-bearing-capacity pile and construction method thereof

A bearing capacity and pile body technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as difficult to pull out and deep depth of ordinary piles, and achieve the effect of low cost, high rigidity, strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below by specific examples.

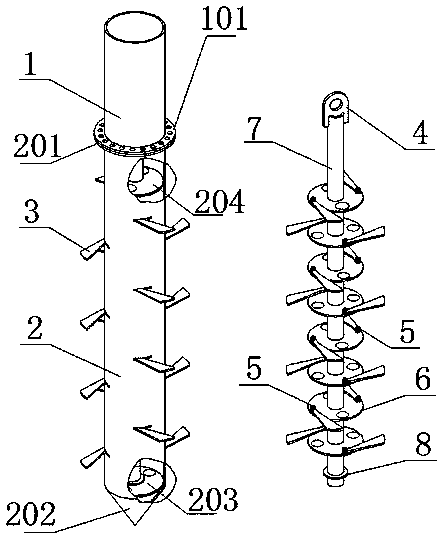

[0020] Such as figure 1 Shown, a kind of high-bearing-capacity pile comprises, upper pile body 1, lower pile body 2, load-bearing cutting block 3 buried in the soil, rotating lever connecting block 4, connecting bolt 5, pile core rotating disk 6, pile core 7 and pile core card Ring 8; one of them, the lower end of the upper pile body 1 is welded with a pile flange 101 for connecting with the lower pile body; the upper end of the lower pile body 2 is provided with a welding flange 201 for connecting the upper pile body 1; The lower end of the lower pile body 2 is provided with a pile point 202, which is convenient for piling into the soil; pile partitions 203 and 204 are welded near its two ends, and a grouting hole and a center hole are arranged on it, and a rotating pair is formed with the pile core 7; The body is provided with a hole of a specific shape, which is used to enter and exit the pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com