Single-cavity axial-flow piezoelectric pump with valve and driving method

An axial flow, piezoelectric pump technology, applied in the direction of variable displacement pump parts, pumps with flexible working elements, parts of pumping devices for elastic fluids, etc. Limiting the maximum opening degree of the valve, affecting the stable output of the pump, etc., to achieve the effect of increasing the opening degree, increasing the output flow, and improving the flow output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

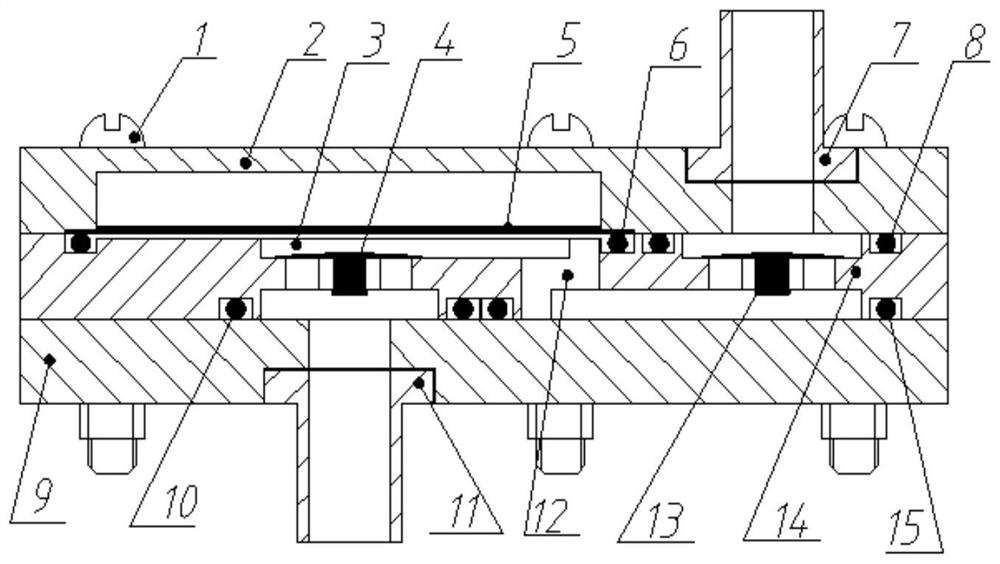

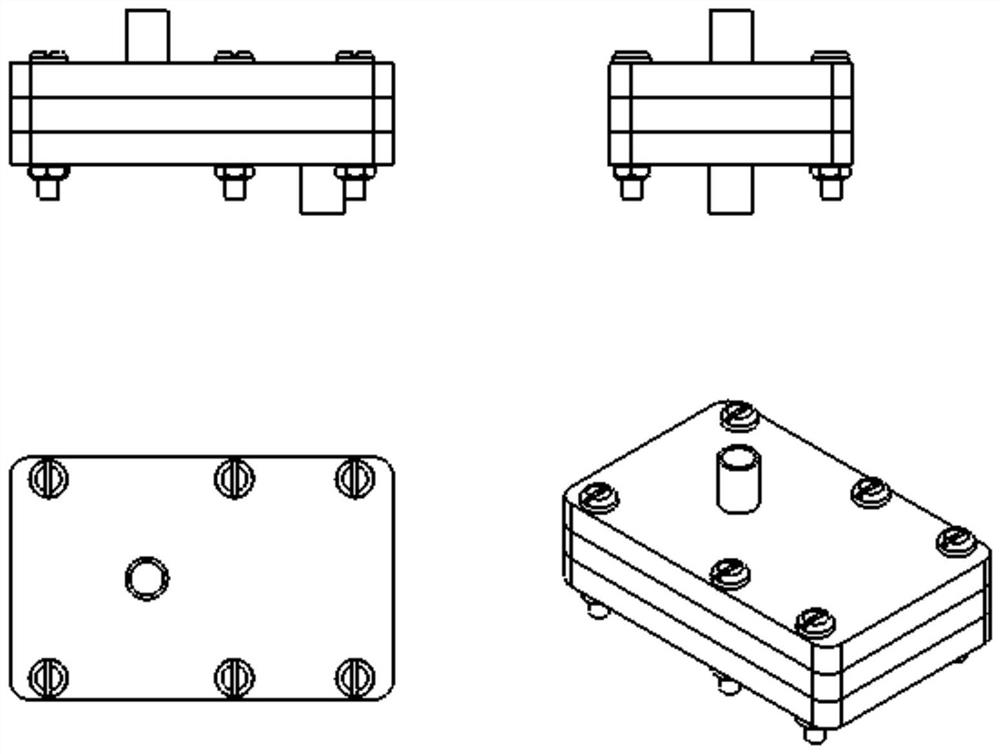

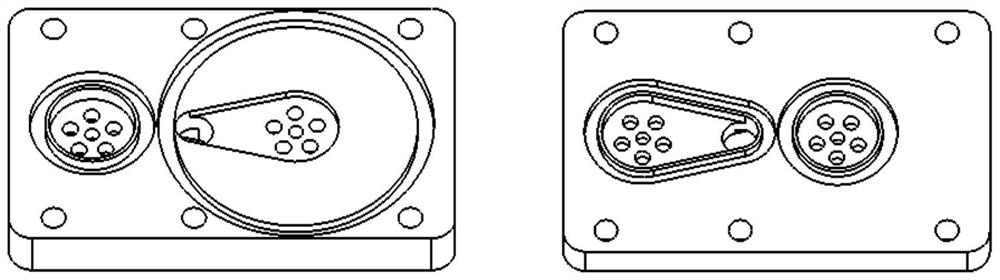

[0027] The invention discloses a single-cavity axial-flow piezoelectric pump with a valve. The pump body structure is mainly composed of three parts, namely the upper cover for fixing the piezoelectric vibrator, the intermediate body with cavity structure and passive stop valve, and the lower cover for pressing and sealing.

[0028] Such as Figure 1-4 As shown, the alternating voltage acts on the piezoelectric vibrator for one cycle. When the circular piezoelectric vibrator 5 vibrates upward, the volume of the pump chamber 3 becomes larger, and the external ambient pressure acting on the inlet valve 4 is greater than the internal pressure of the pump chamber. , the inlet valve is gradually opened, and the fluid enters the pump chamber through inlet 11. When the piezoelectric vibrator vibrates downward, the volume of the pump chamber becomes smaller, the external ambient pressure acting on the inlet valve is lower than the internal pressure of the pump chamber, the outlet val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com