Life cycle management and analysis method for waste incineration special equipment

A life cycle and special equipment technology, applied in the direction of registration/indicating machine production, instruments, etc., can solve problems such as equipment management difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be specifically described below in conjunction with the accompanying drawings.

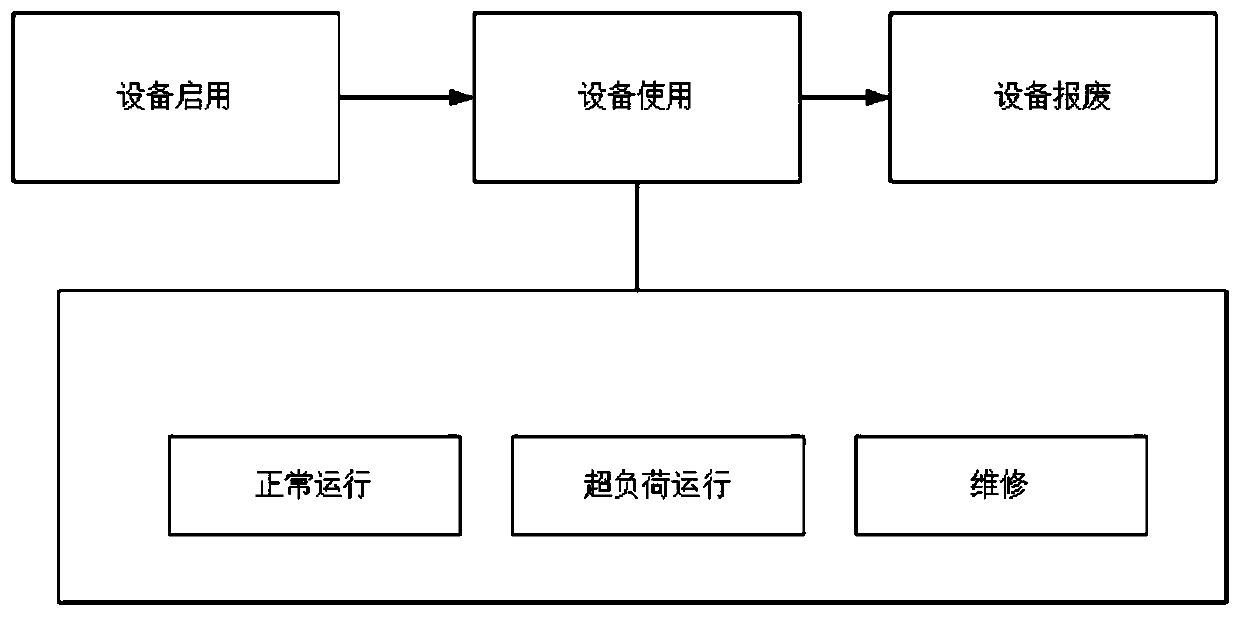

[0017] as attached figure 1 A life cycle management and analysis method for special waste incineration equipment, characterized in that it includes the following steps:

[0018] Step 1: Before the equipment is put into use, combined with the instructions for use of the equipment, set the full life cycle time T of a special equipment in a waste incineration enterprise.

[0019] Step 2: When the device is enabled, collect the cumulative operating time t1 of the device, the time t2 of the device running with defects, and the time t3 of the device running beyond the rated operating power; the calculation formula for the life cycle time consumed by the device during the operating phase is: t1+t2 *m+t3*n+t4, where m is the preset defect compensation coefficient, n is the preset compensation coefficient for over-rated working conditions, and t4 is the preset compensati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap