Coke filter

A filter and coke technology, used in gravity filters, filtration separation, loose filter material filters, etc., can solve problems such as equipment and pipeline blockage, achieve low operating resistance, meet production needs, and use a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

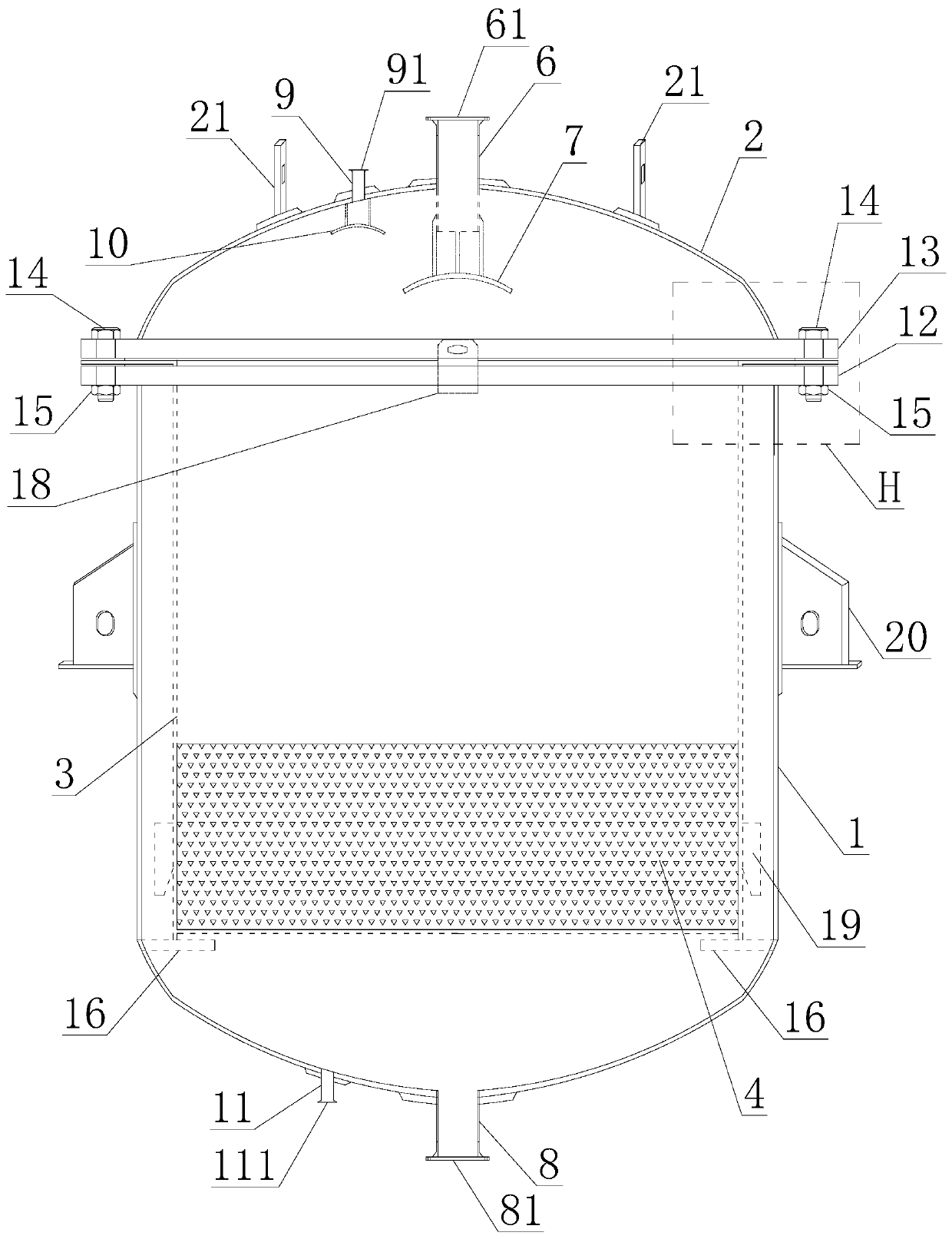

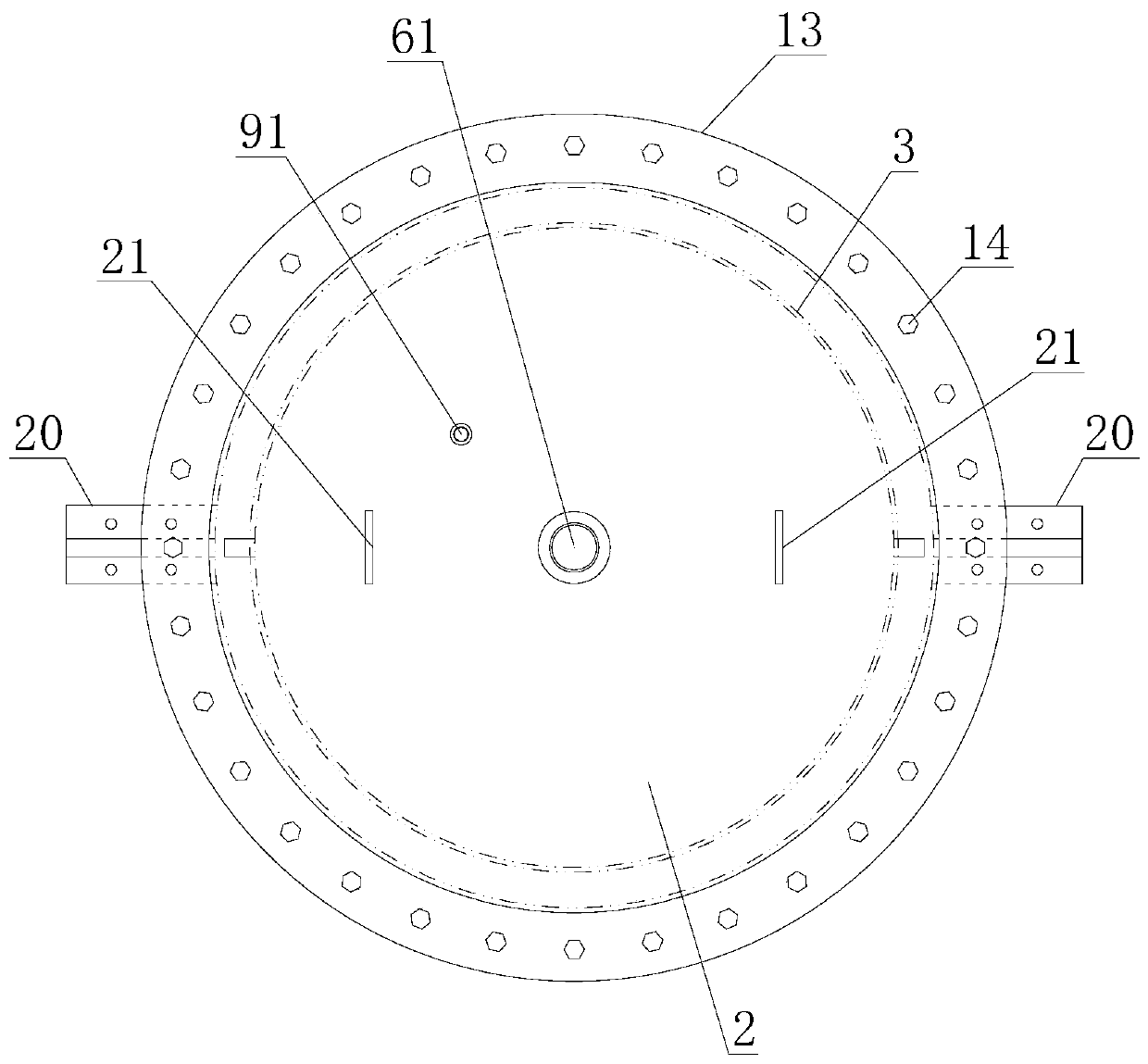

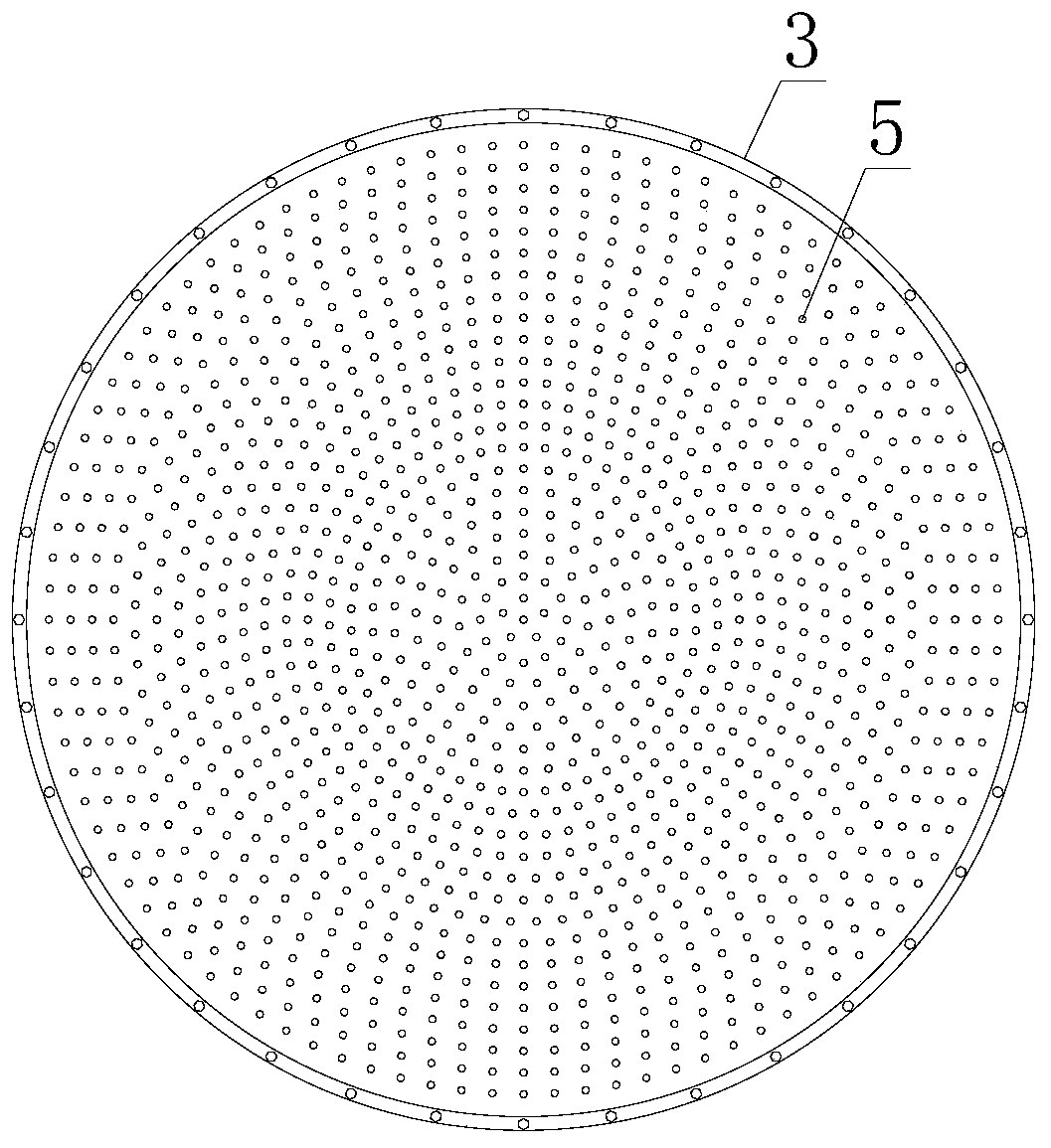

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the described coke filter includes an outer cylinder 1 with an open top and an elliptical head at the bottom, a cylinder cover 2 is provided at the opening of the outer cylinder 1, and a top open In the inner cylinder 3 of the mouth, a packing layer 4 composed of coke is laid in the inner cylinder 3, and mesh holes 5 are uniformly distributed on the body and bottom of the inner cylinder 3 covered by the packing layer 4, and on the bottom of the cylinder cover 2 A liquid inlet 6 is provided in the center of the top, and a liquid inlet valve 61 is arranged at the liquid inlet 6. A first backsplash arc plate 7 with the arc facing downward is arranged directly below the liquid inlet 6. Through the first backsplash The arc plate 7 can realize uniform liquid distributi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap