High-efficiency energy-saving dust removal equipment

A dust-removing equipment, high-efficiency and energy-saving technology, applied in the fields of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problem of fast replacement frequency of the filter screen, and achieve the effect of reducing the filter burden, prolonging the service life, and reducing the number of replacements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

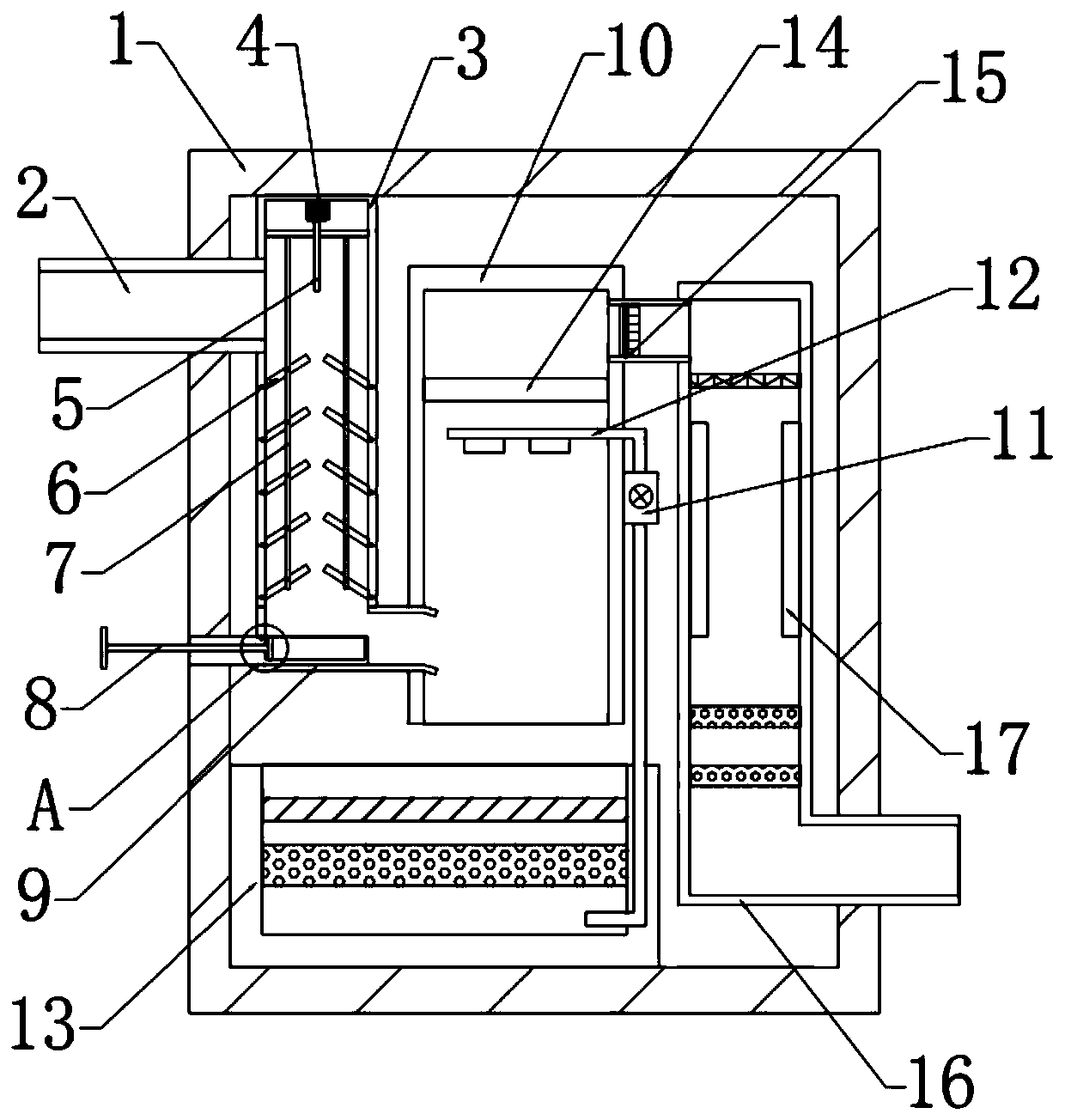

[0026] see Figure 1~3 , in an embodiment of the present invention, a high-efficiency energy-saving dust removal device includes a housing 1, an air intake pipe 2 is provided on the left side of the housing 1, the output end of the air intake pipe 2 is connected to a filter pipe 3, and the filter pipe 3 The top end is fixedly connected with the housing 1, a cleaning pipe 10 is arranged on the right side of the filter pipe 3, a connecting pipe 9 is arranged between the cleaning pipe 10 and the filter pipe 3, and the top of the right side of the cleaning pipe 10 is fixedly connected with a An air guide tube, the other end of which is connected to an air outlet tube 16, and a blower fan 15 is arranged in the air guide tube.

Embodiment 2

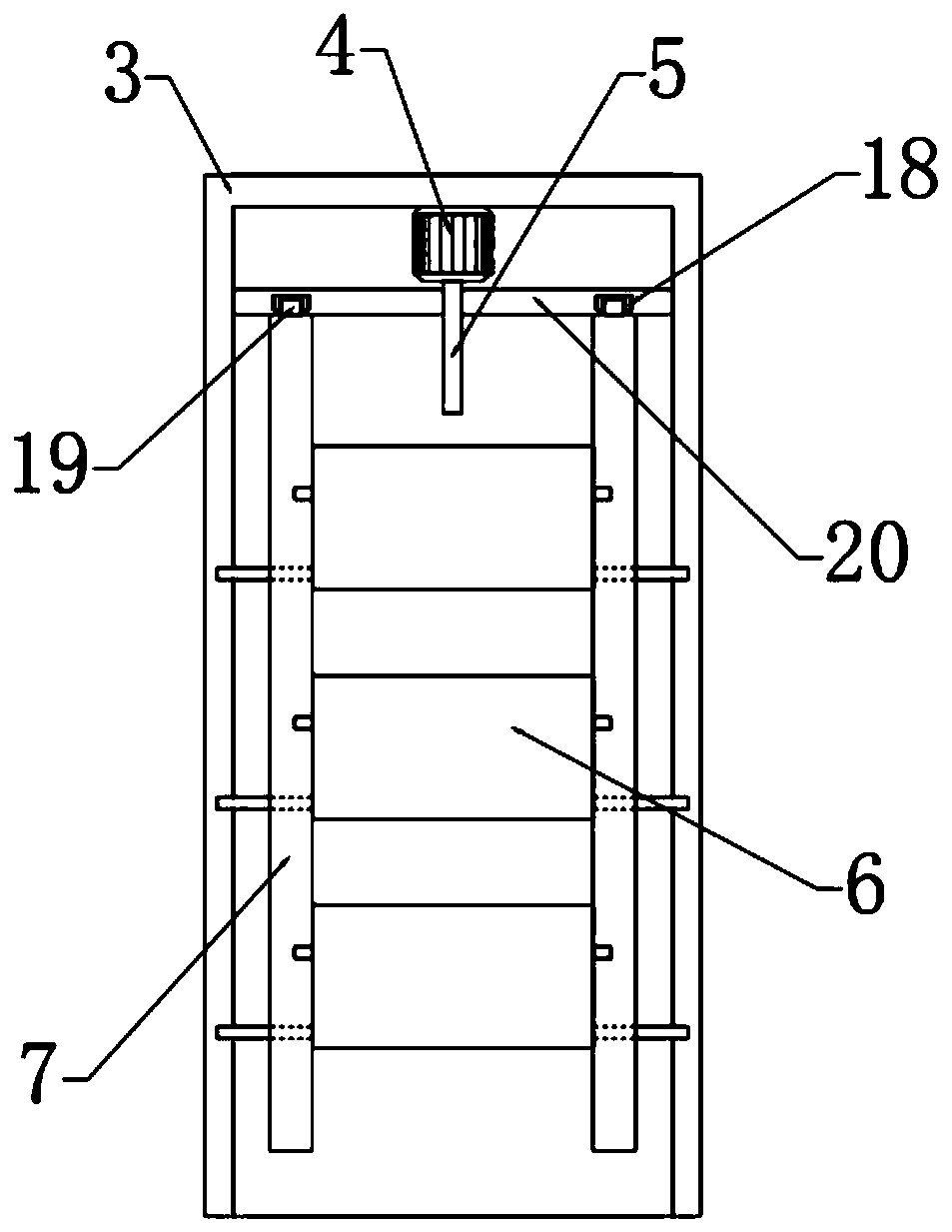

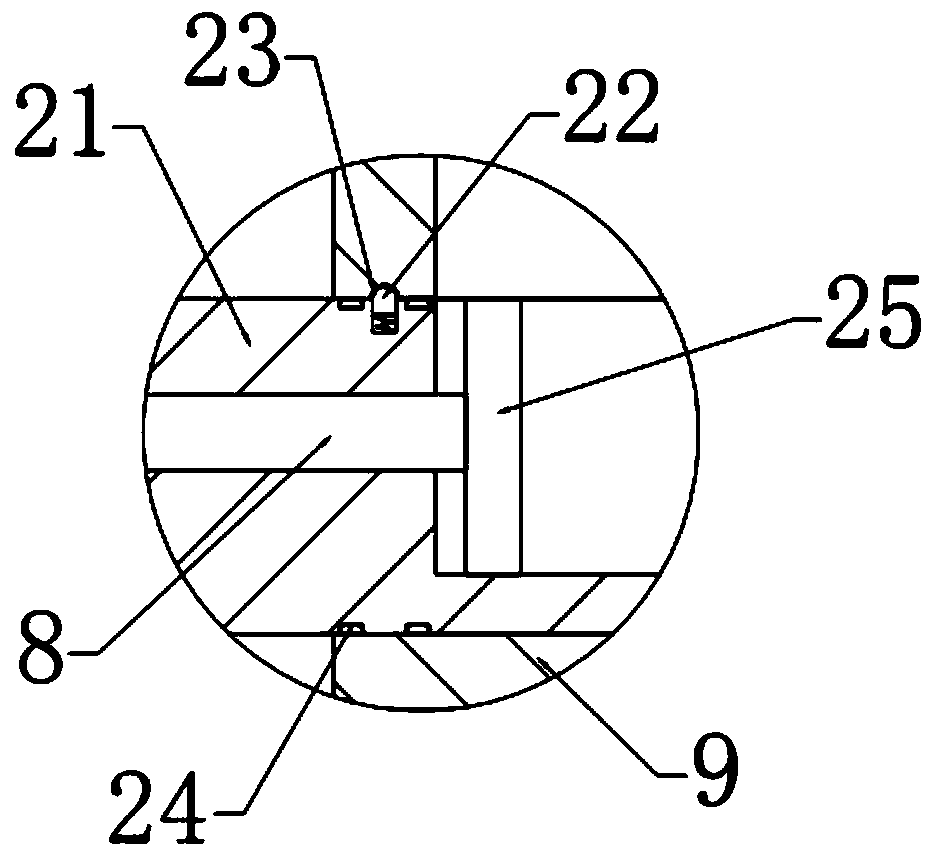

[0028] In this embodiment, a plurality of baffles 6 are hingedly arranged on the inner side of the filter tube 3, the front and rear sides of the baffles 6 are connected to the driving mechanism, and the lower side of the baffles 6 is provided with a dust collection mechanism. The dust collection mechanism is clamped with the connecting pipe 9.

[0029] In this embodiment, the drive mechanism includes a motor 4, a threaded rod 5 and a connecting rod 7, the motor 4 is bolt-connected and arranged on the inner top end of the filter tube 3, and the lower output end of the motor 4 is connected to the threaded rod 5, so Said threaded rod 5 outer thread connection is provided with the fixing plate 20 that is slidingly connected with the filter tube 3 pipe walls, and the front and rear sides of the bottom end of the fixing plate 20 are all slidingly connected to be provided with connecting rods 7, and the connecting rods 7 and the baffle plate 6 Hinged, by setting the driving mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com