A bowl male welding fixture

A welding fixture and clamping technology, applied in the field of fixtures, can solve the problems of affecting the diversion effect of the diversion groove, difficulty in maintaining stable contact, and generation of defective products, so as to facilitate precise welding, improve production efficiency and product quality , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

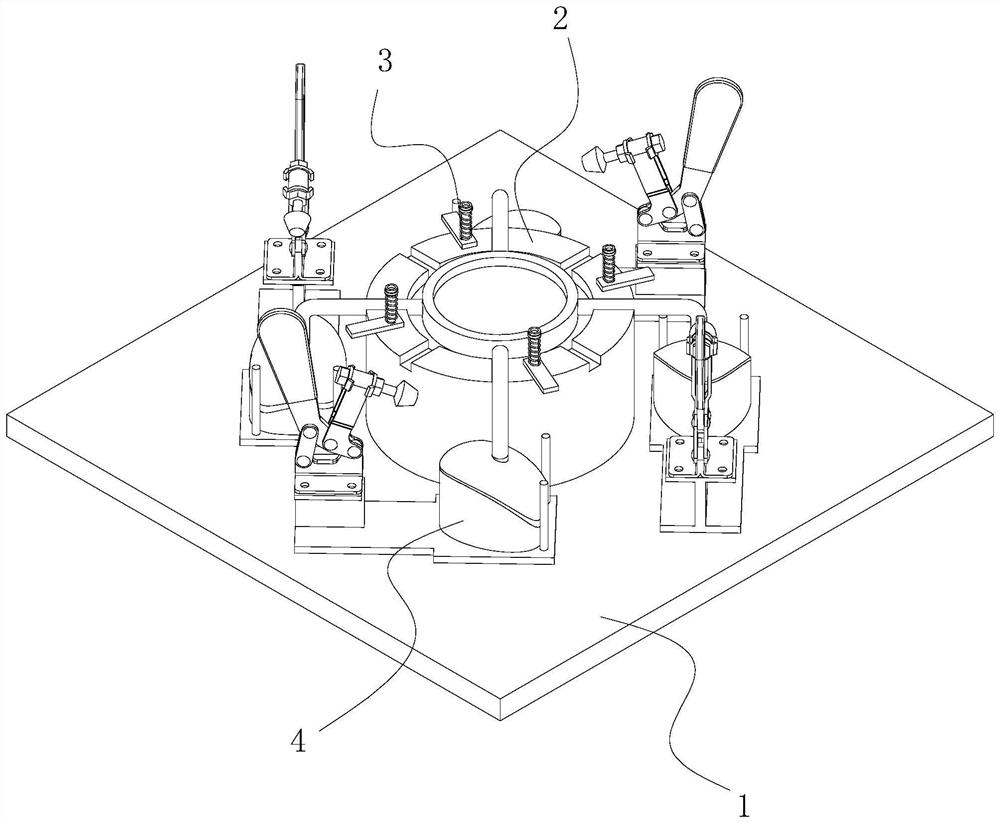

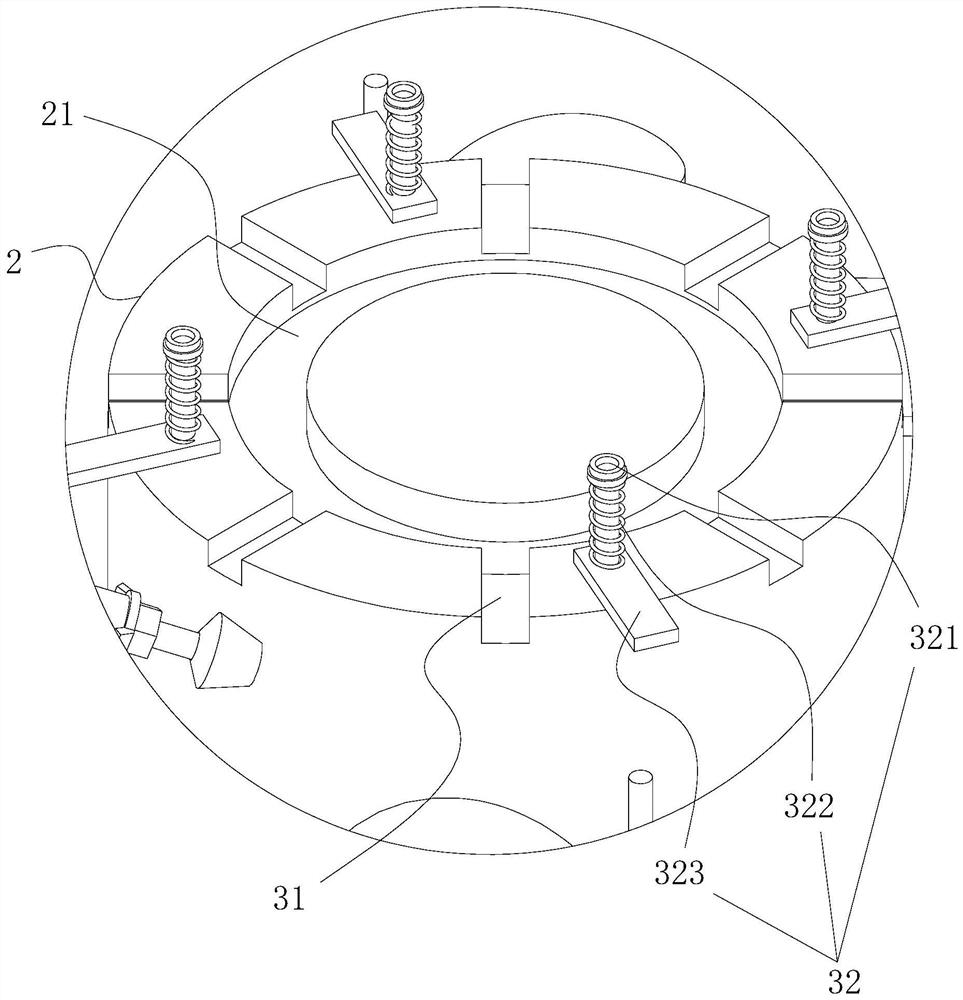

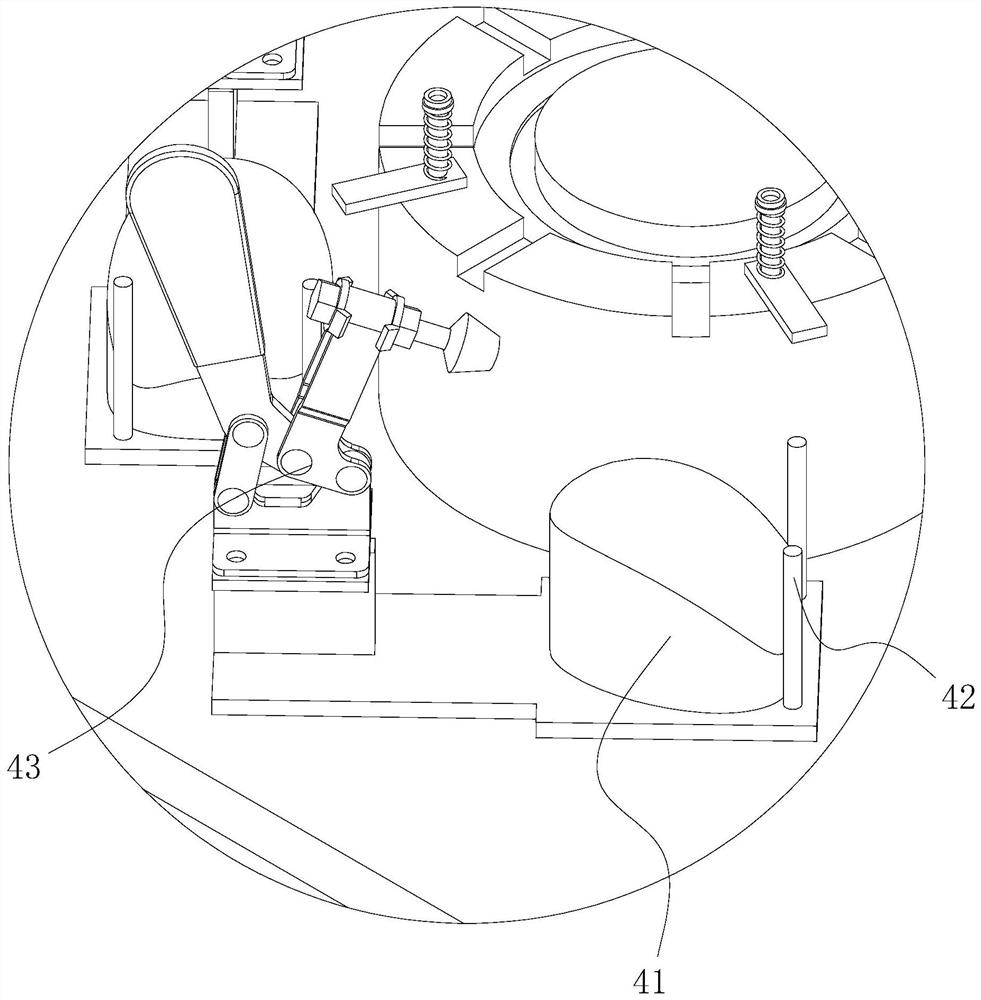

[0045] Embodiment 1: A bowl male welding fixture, such as figure 1 As shown, it includes a base 1 which plays a main supporting role, a fixed plate positioning seat 2 arranged at the center of the base 1 for positioning and placing of the fixed plate, and a fixed plate positioning seat 2 arranged at the edge of the upper end surface of the fixed plate positioning seat 2 for The rod body clamping assembly 3 for the clamping and positioning of each rod body and the diversion groove clamping assembly 4 arranged on the base 1 for the positioning and clamping of each diversion groove; wherein, when the fixed plate is installed on the fixed plate When inside the positioning seat 2, the fixed plate and the fixed plate positioning seat 2 are arranged on the same axis. Arranged in a circumferential equidistant array, when each rod body is installed on the rod body clamping assembly 3, the axis of each rod body ring fixed plate positioning seat 2 is arranged in a circumferential equidis...

Embodiment 2

[0049] Embodiment two: if Figure 4 As shown, this embodiment is an optimized solution of Embodiment 1. Specifically, the optimized structure of this embodiment includes a base 1 , a fixing plate positioning seat 2 , a rod body clamping component 3 and a diversion groove clamping component 4 .

[0050] combine Figure 4 and Figure 5 As shown, in the second embodiment, the base 1 includes a fixed seat 11 and a movable seat 12 that is rotatably connected to the fixed seat 11 and the rotating shaft is vertically arranged. On the fixed seat 11, the axis of several ring fixed seats 11 is rollingly connected. Circumferentially equidistantly arranged and the outer wall and the lower surface of the movable seat 12 abut against the roller 13 used to assist the rotation of the movable seat 12, the fixed plate positioning seat 2, the rod body clamping assembly 3 and the diversion groove clamping assembly 4 are all Be arranged on the movable seat 12; Wherein, on the movable seat 12, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com