Sealed gas intake device for storage tank

A technology of gas device and gas extraction device, which is applied in the field of airtight gas collection device for storage tanks, which can solve the problems of energy waste and space waste of the device, and achieve the effect of small workload and fast connection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

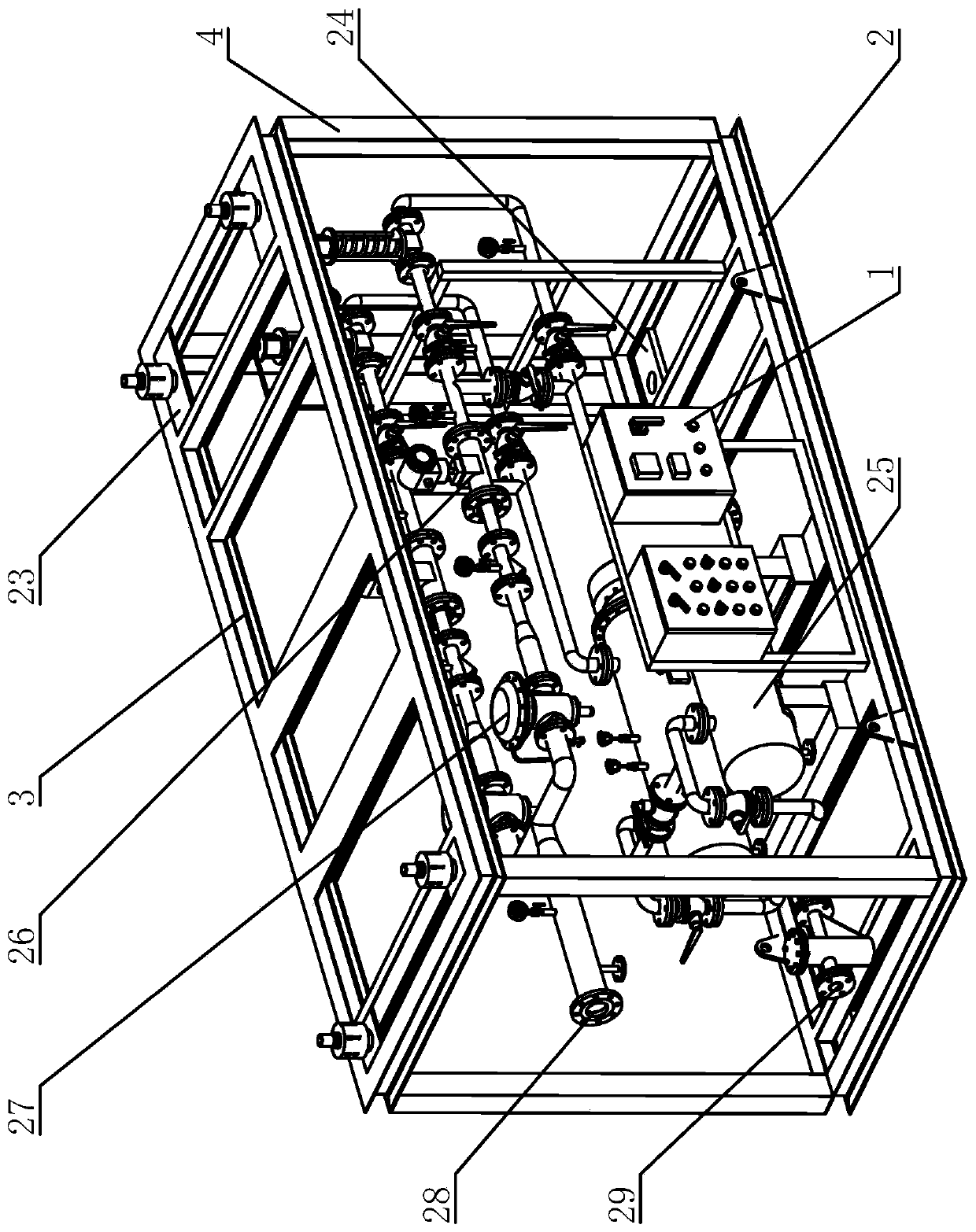

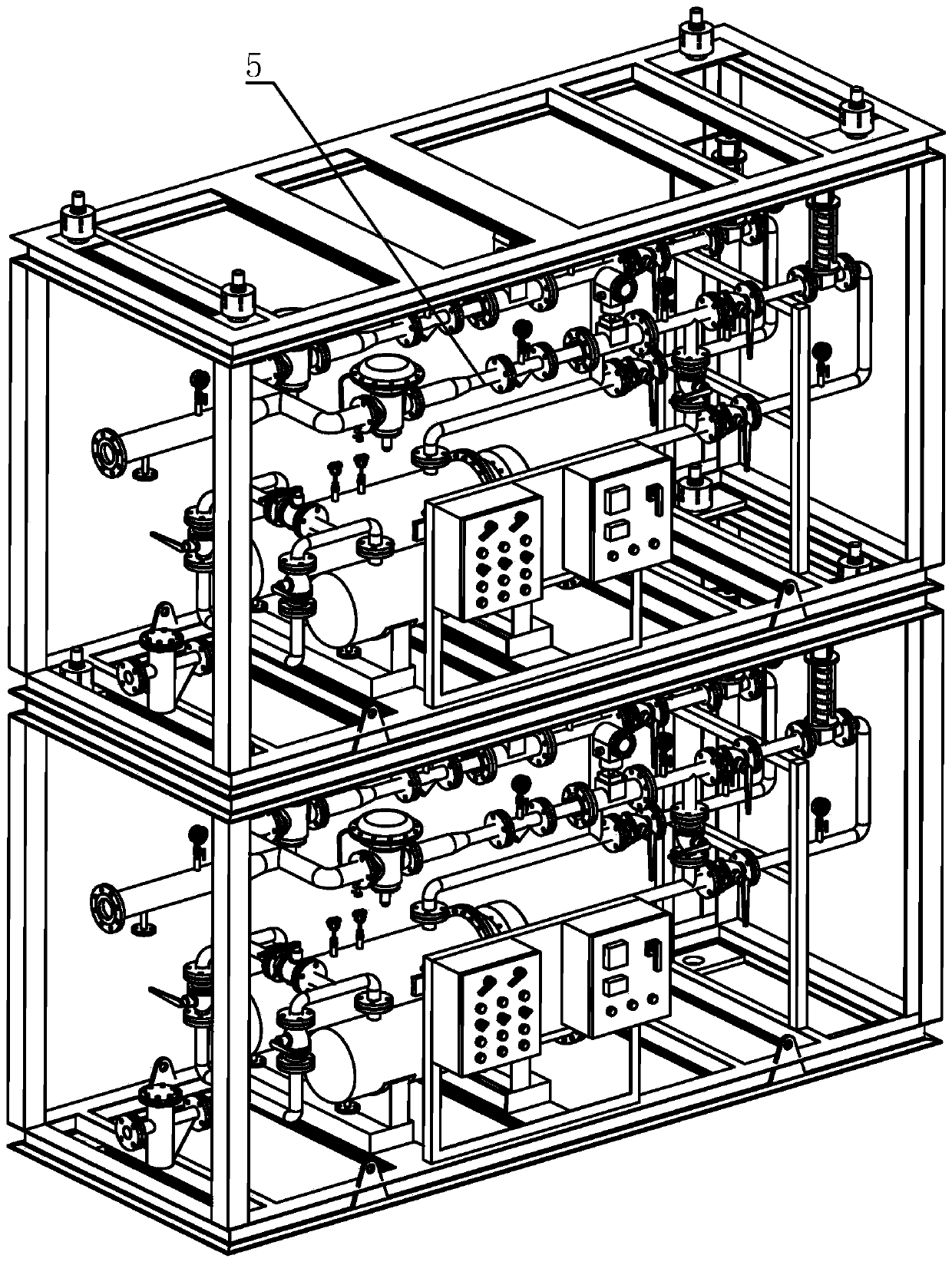

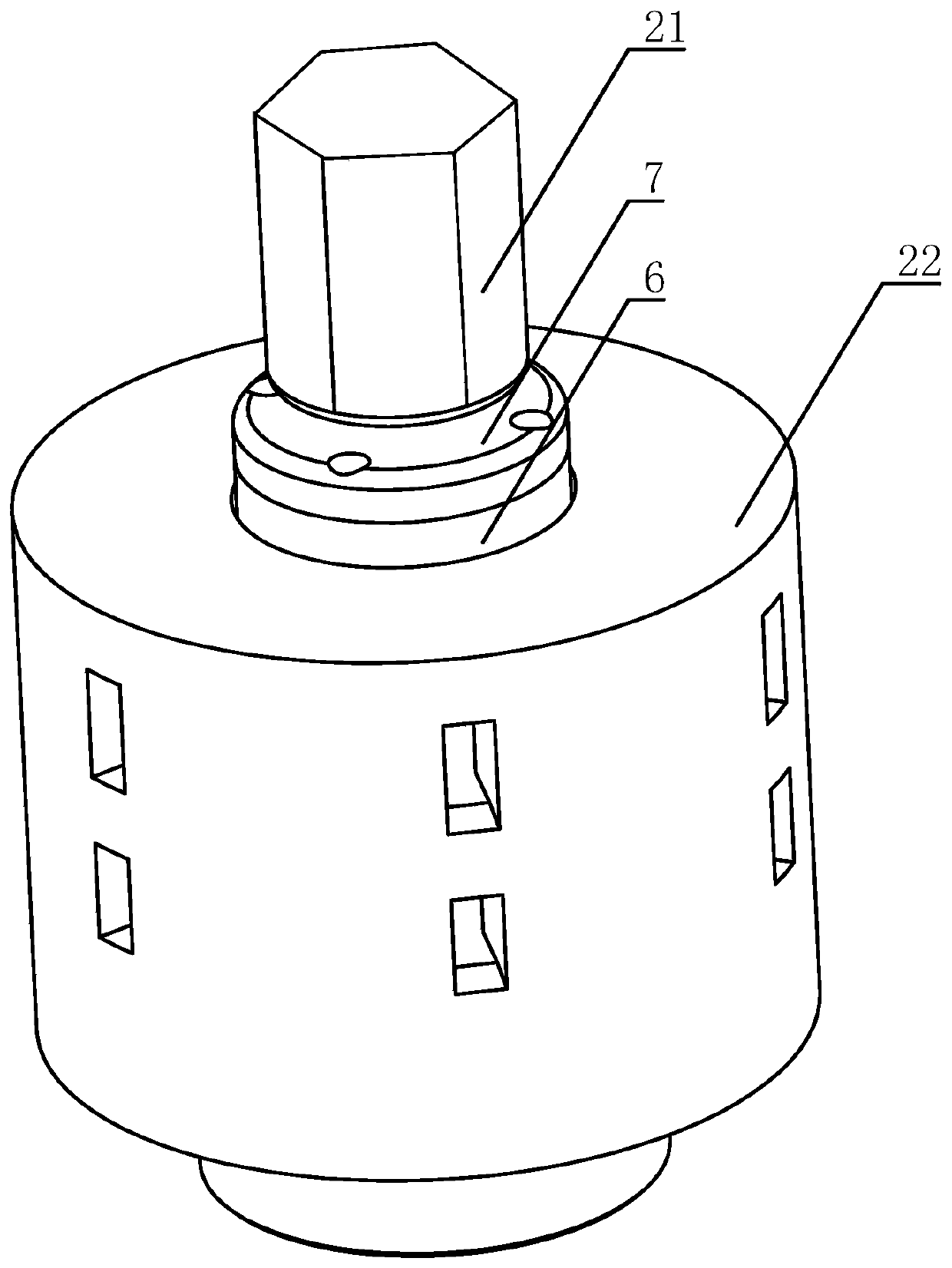

[0029] Embodiment: airtight storage tank air collection device, including frame, air extraction device 5, control cabinet 1 and connecting structure, said frame includes bottom frame 2, top frame 3 and column 4, and said bottom frame 2 is a square frame structure, The top frame 3 is the same square frame structure as the bottom frame 2, the bottom of the column 4 is welded to the four corners of the top surface of the bottom frame 2, the bottom surface of the top frame 3 is welded to the top of the column 4, and the top frame 3 is connected to the bottom frame. 2 corresponding to the height direction, the top surface of the top frame 3 is provided with connecting plates 23 at the four corners, and the bottom frame 2 is provided with fixing plates 24 at the four corners of the bottom surface. The frame as a whole is welded by channel steel.

[0030] The air extraction device 5 is installed on the chassis 2, and the air extraction device 5 has two channels, one for use and one f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com