Large debugging jacking sliding device and sliding method thereof

A sliding device and jacking technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of tight delivery time, heavy tasks, and shortage of floating crane resources, and achieve the effect of facilitating maintenance and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

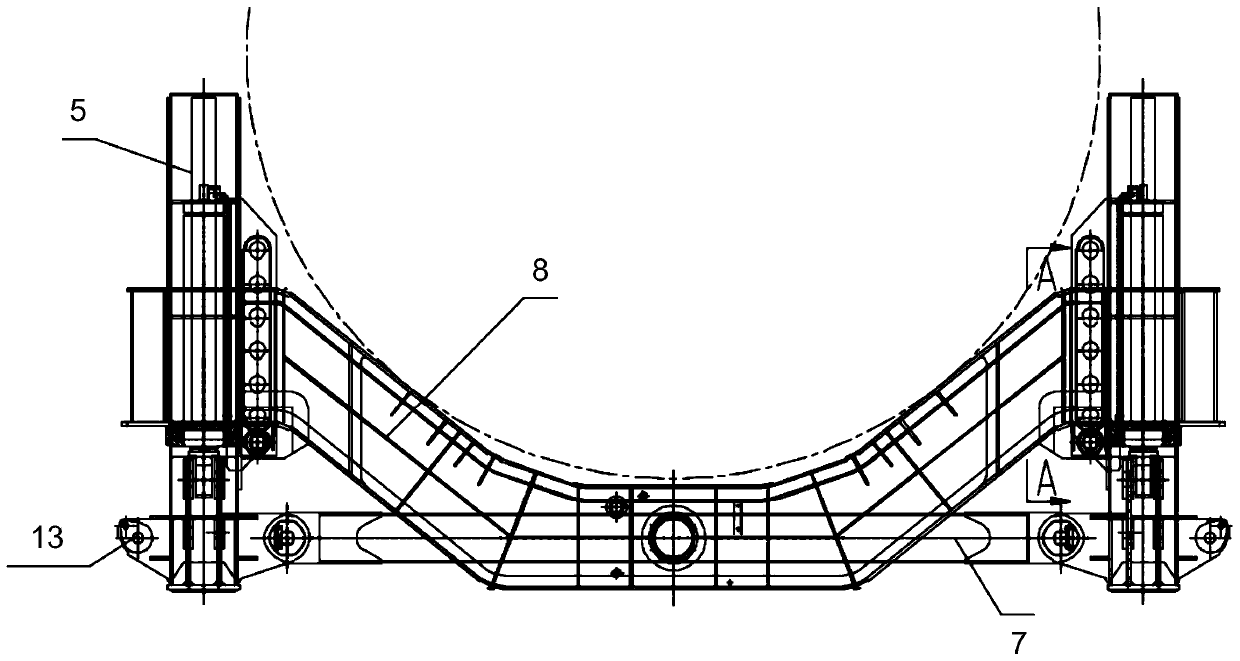

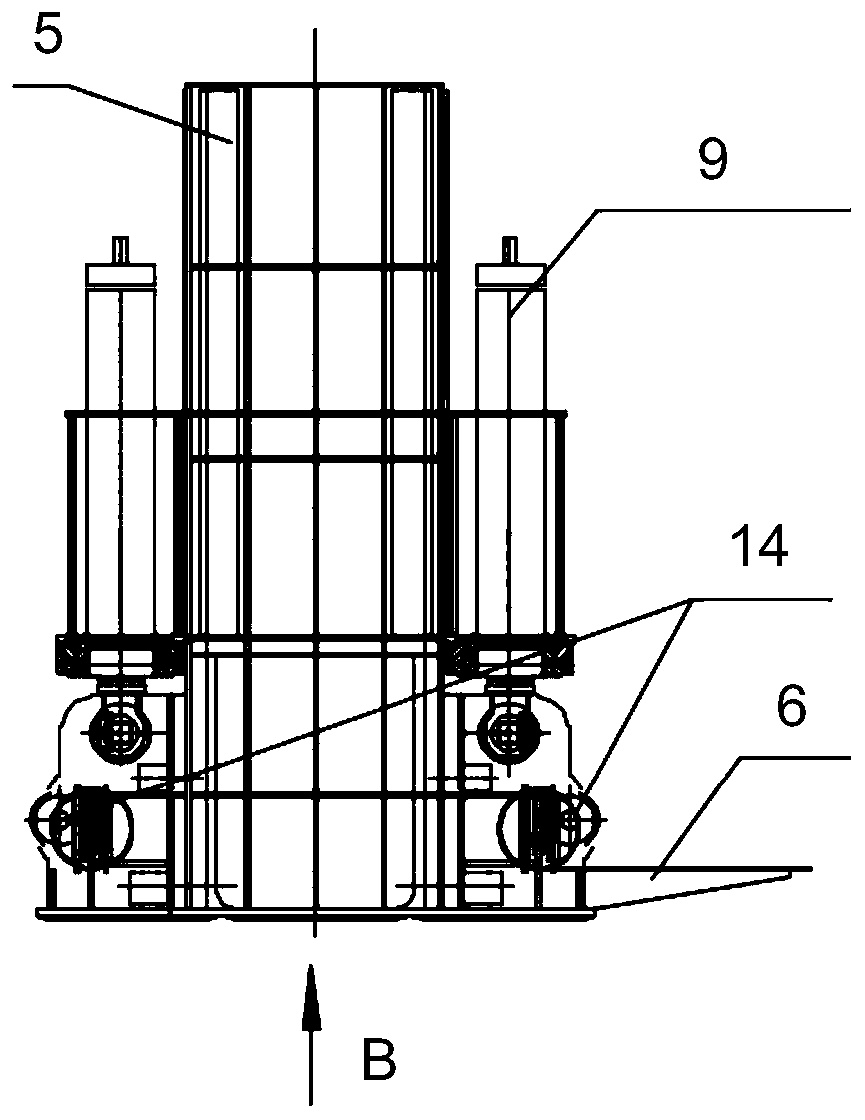

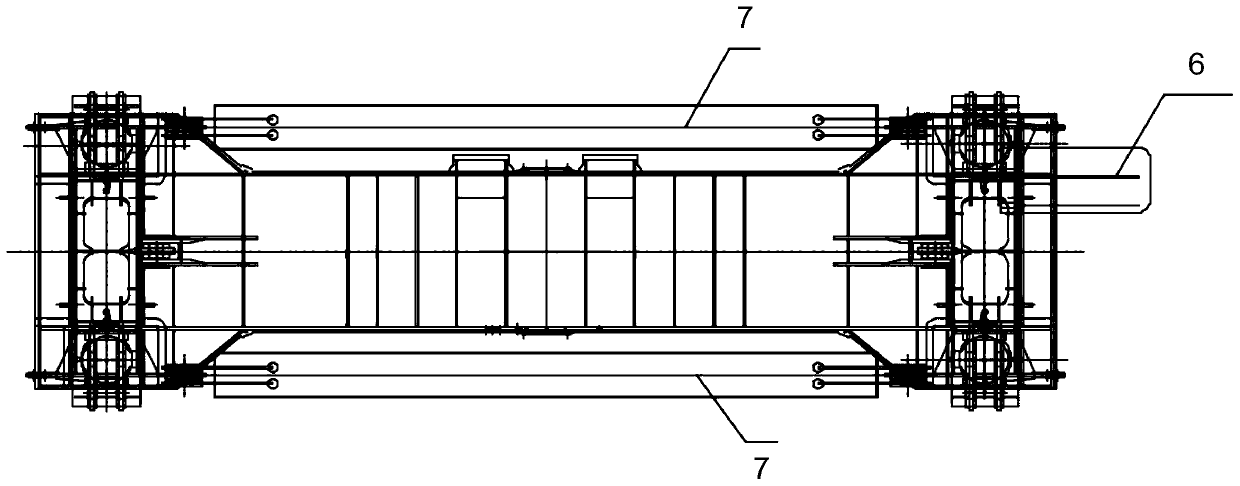

[0044] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0045] Please combine Figure 1 to Figure 9 As shown, a large-scale adjustable jacking and sliding device provided by the present invention is installed on the transport ship 100 and the wharf 200 respectively, including the track 1 laid on the transport ship 100 and the track laid on the wharf 200 2. Two blocks are installed on the rails 1 and 2 of the transport ship 100 and the wharf 200, and each block is equipped with jacking and sliding tooling, and is arranged front and back on the slideways 1 and 2. The transport ship 100, The wharf 200 is also equipped with two total lifting lugs 3 and two winches 4. The total root lifting lugs 3 and the winches 4 are installed on the deck at the front end of the tracks 1 and 2 and on the ground of the wharf, and are respectively installed on the slideway 1, The positions on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com