A hot melt emulsion marking machine

A marking machine and emulsion technology, applied in the field of transportation, can solve problems affecting the construction quality of vibration markings and uneven distribution of protrusions, and achieve the effect of improving construction quality and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

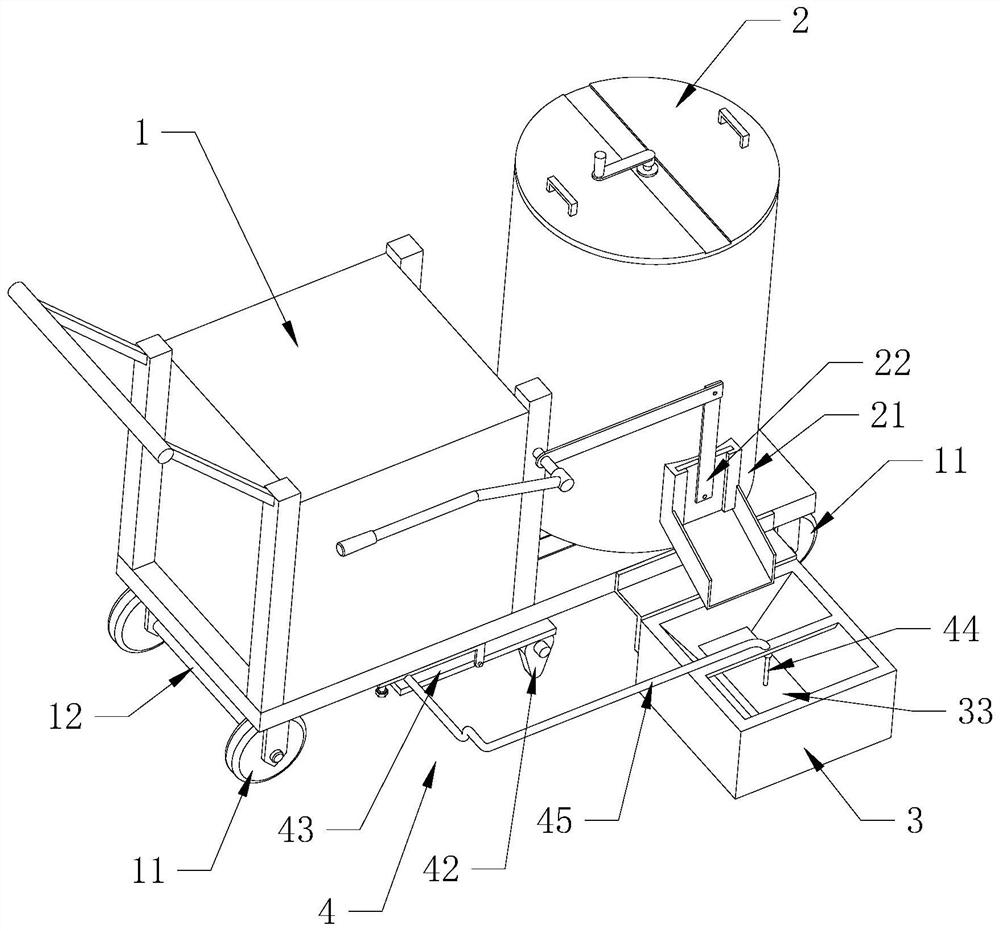

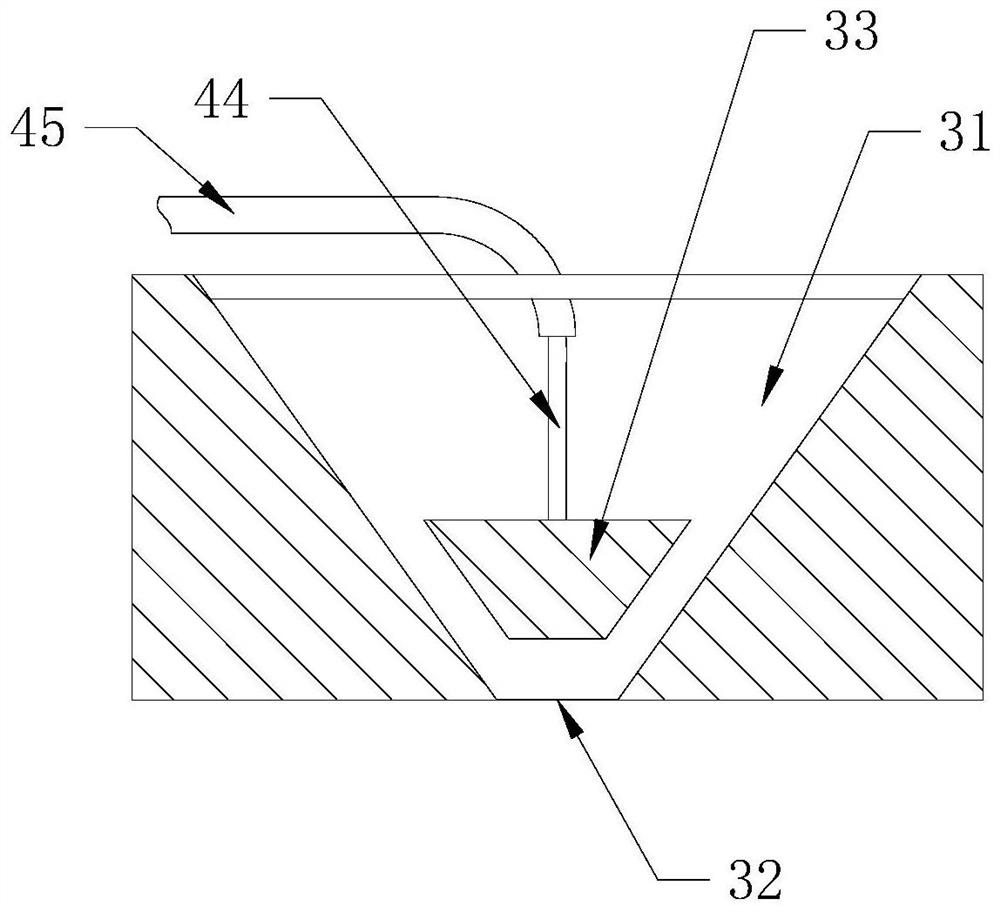

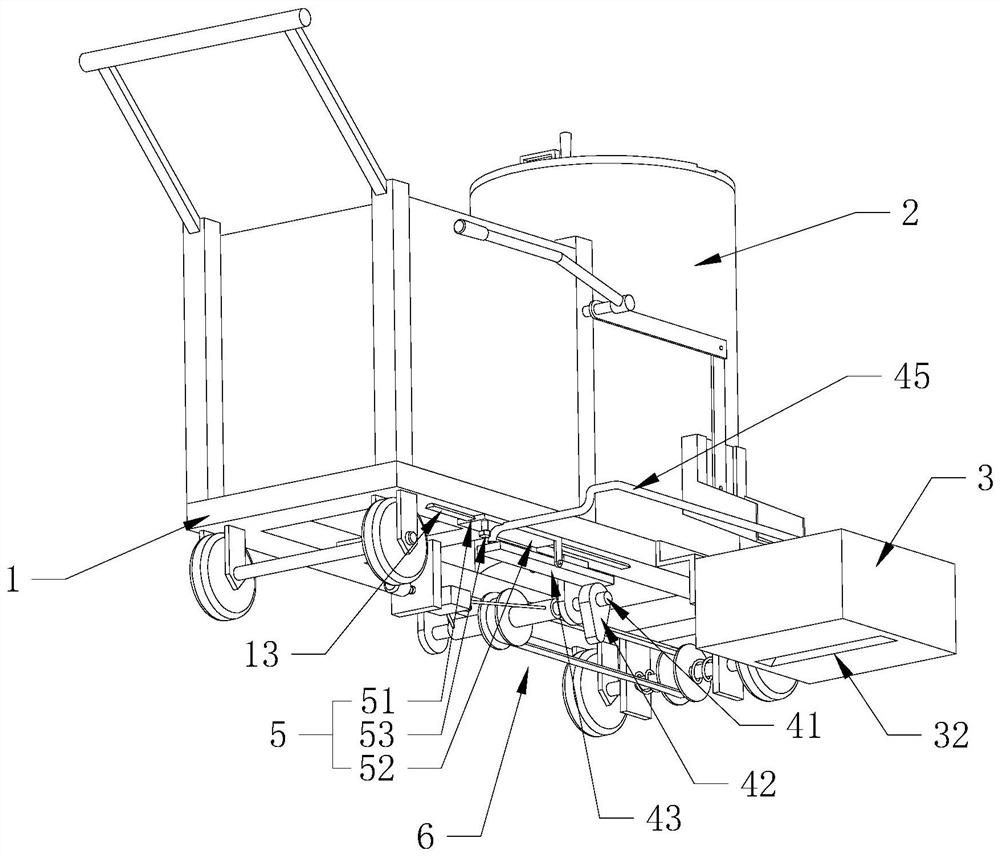

[0042] refer to figure 1 and figure 2 , is a hot-melt emulsion marking machine disclosed in the present invention, comprising a vehicle frame 1, a wheel 11 and a wheel shaft 12 arranged below the vehicle frame 1, a paint bucket 2 is arranged above the vehicle frame 1, and the paint bucket 2 is provided with an outlet The material outlet 21 and the switch gate 22 covering the material outlet 21 are provided with a coating bucket 3 on the vehicle frame 1 and below the material outlet 21, and a V-shaped and penetrating coating bucket 3 is provided along the vertical direction. A through hole 31, the lower end of the through hole 31 forms a marking opening 32, the heated paint is added to the paint bucket 2, then the marking machine is pushed to the construction point, and the switch gate 22 is opened so that the paint overflows from the discharge port 21 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com