Material abandoning control method and device for sampling machines, medium and equipment

A control method and sampling machine technology, applied in conveyor control device, sampling device, program control and other directions, can solve the problems of coal sample accumulation, hidden danger of train running, etc., and achieve the effect of no hardware cost, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

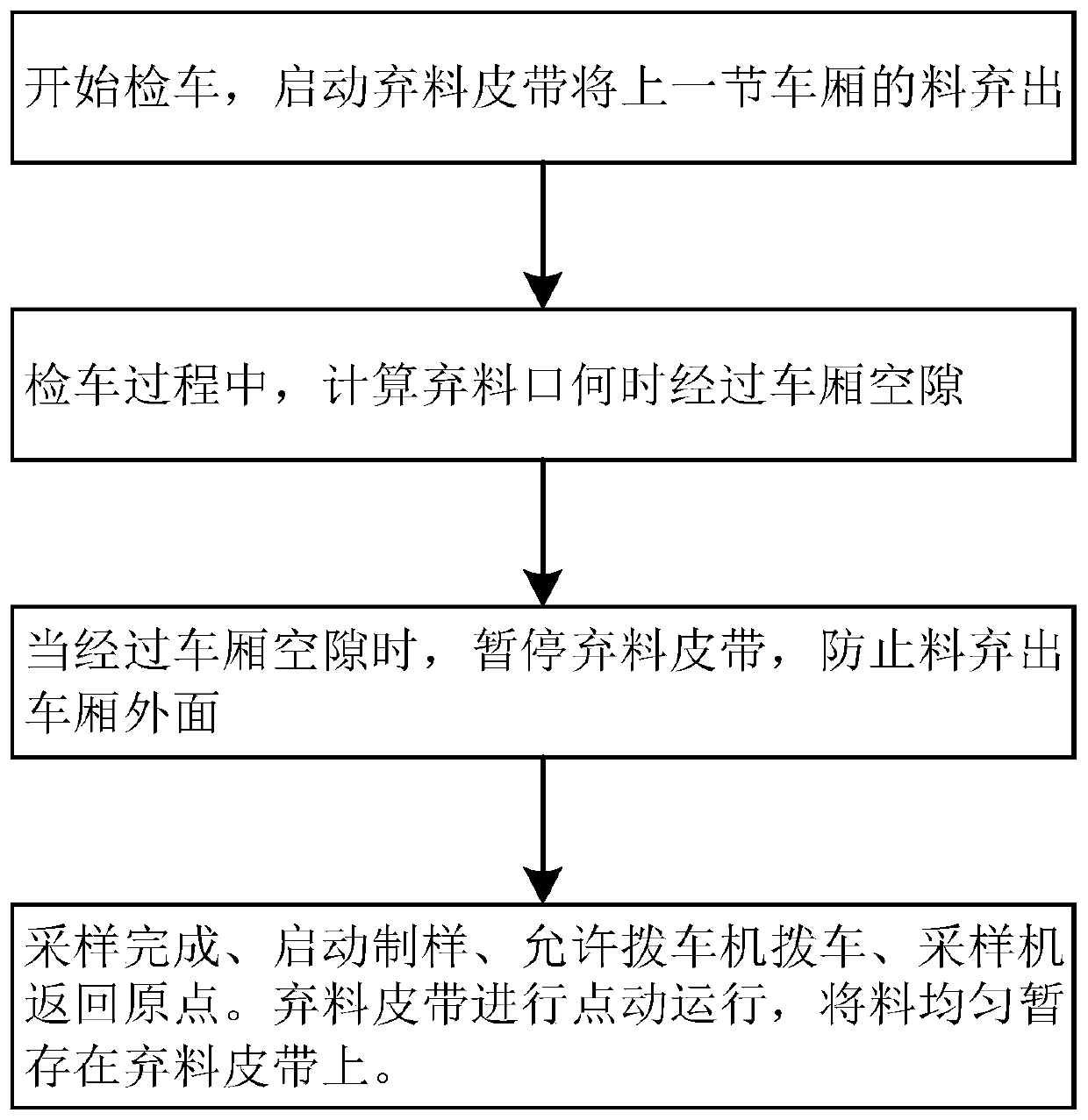

[0040] like figure 1 As shown, the discarding control method of the sampler of the present embodiment comprises steps:

[0041] S01. During the operation of the sampling machine (such as the train sampling machine) at two adjacent target sampling points, and during the process of discarding the material, detect in real time whether the material discarding port of the sampling machine is located in the compartment between the two adjacent target sampling points gap position;

[0042] S02. When the material discarding port is located at the position of the compartment gap, stop the material discarding operation of the sampling machine.

[0043] The material discarding control method of the sampling machine of the present invention, in the process of checking the vehicle (finding the target sampling point) (carrying out the material discarding operation in this process), detects in real time whether the material discarding port is located between two adjacent target sampling poi...

Embodiment 2

[0059] The difference between this embodiment and the first embodiment is only that the recording point L0 of the initial position of the sampling machine in step S012 is different. specifically,

[0060] Step S01 is specifically:

[0061] S11. After the single sampling and sampling operation of the sampling machine is completed, when the sampling machine starts to travel to the next target sampling point, the waste material operation is started, and the waste material is transported to the carriage through the waste material belt;

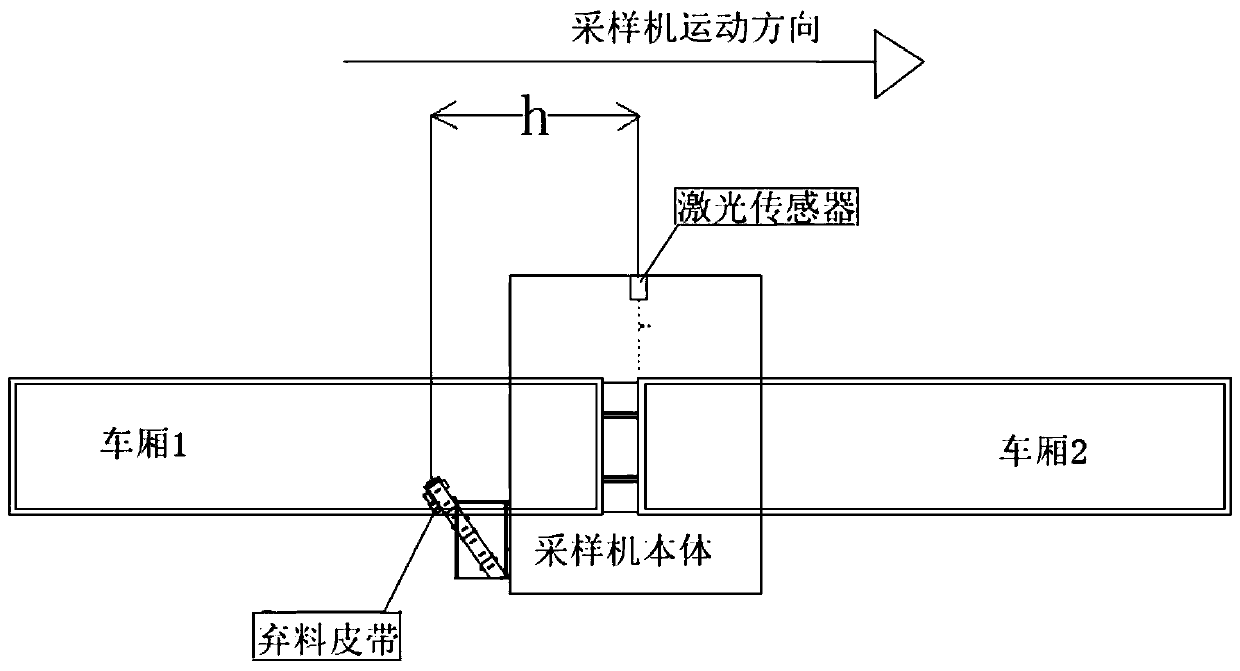

[0062] S12. When the output signal of the vehicle inspection laser sensor jumps for the first time, the frame of the current car is detected, and the position value L0 of the sampling machine at this time is recorded through the rotary encoder of the sampling machine;

[0063] S13. The sampling machine continues to travel to the target sampling point. When the sampling machine travels to the position L0+h

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com