Lithium-ion battery structure design method

A lithium-ion battery, structure design technology, applied in the direction of secondary battery, secondary battery manufacturing, non-aqueous electrolyte storage battery, etc., can solve the problems of low energy density, lithium battery diaphragm damage, battery overheating, etc., to achieve easy large-scale Batch industrial production, solve the internal short circuit problem, and improve the effect of using safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

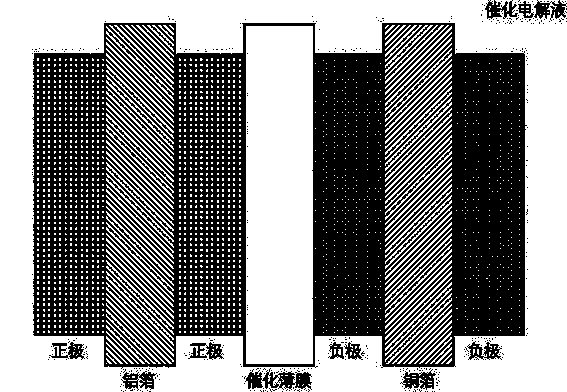

[0025] A "catalytic" structural design method of the positive electrode / electrolyte / film / negative electrode of the present invention specifically includes the following steps:

[0026] (1) Coat the positive electrode material on both sides of the aluminum foil, dry at 80°C for 12 hours and solidify;

[0027] (2) Coat the anode material on both sides of the copper foil, dry at 100°C for 12 hours and solidify;

[0028] (3) Using lamination technology with catalytic film, positive electrode and negative electrode to make it into a battery cell;

[0029] (4) Encapsulate the cell material obtained in the above steps with the catalytic electrolyte.

Embodiment 2

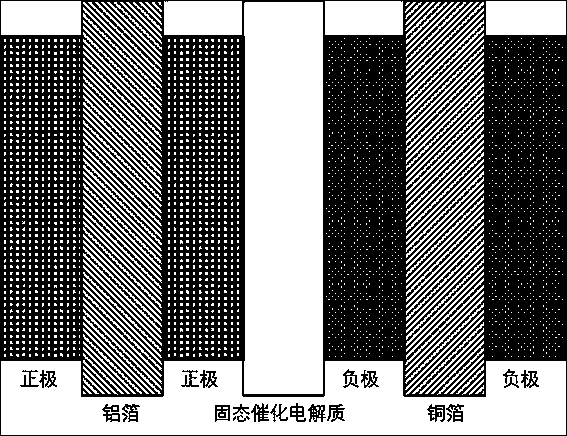

[0031] A "catalytic" structural design method of positive electrode / solid electrolyte / negative electrode of the present invention, specifically includes the following steps:

[0032] (1) Coat the positive electrode material on both sides of the aluminum foil, dry at 80°C for 12 hours and solidify;

[0033] (2) Coat the anode material on both sides of the copper foil, dry at 100°C for 12 hours and solidify;

[0034] (3) Using lamination technology with catalytic solid electrolyte, positive electrode and negative electrode to make it into a battery cell;

[0035] (4) Encapsulate the cell material obtained in the above steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com