Patents

Literature

45results about How to "Ease of industrial production in large quantities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-purity ultra-fine torispherical silicon micro-powder prepared from natural powder quartz ore and preparation method of silicon micro-powder

The invention discloses a high-purity ultra-fine torispherical silicon micro-powder prepared from natural powder quartz ore and a preparation method of the silicon micro-powder. The preparation method comprises the following steps: by taking the cheap natural quartz ore as a raw material, adding inorganic dilueted acid which exerts the grinding aid effect in an ultra-fine grinding machine so as to prepare ore slurry, and regulating the pH of the ore slurry to 2-3; by taking a zirconia ball as a ball-milling medium, grinding for 2-4 hours in the ultra-fine grinding machine; when the power of which the particle diameter is 2mu m reaches 60%-90% in the high-purity ultra-fine silicon powder, adding reductant sodium hydrosulfite and complexing agent oxalic acid, wherein the dosage of the reductant sodium hydrosulfite is 1-2% of weight of ore powder, and the dosage of the complexing agent oxalic acid is 0.5-1-5% of weight of ore powder; and after continuing to grind for a while, washing, filtering and drying. An ultrafine processing technology and a purification and bleaching technology are simultaneously achieved in the same equipment; and the preparation method has the advantages of simple process, short flow, low cost and obvious purification effect, and is easy to carry out large batch production on scale; and the product can be applied to the fields of electronics, electricians, optical fibers, lasers, aerospace and the like.

Owner:HUNAN JINMA NEW MATERIAL TECH CO LTD

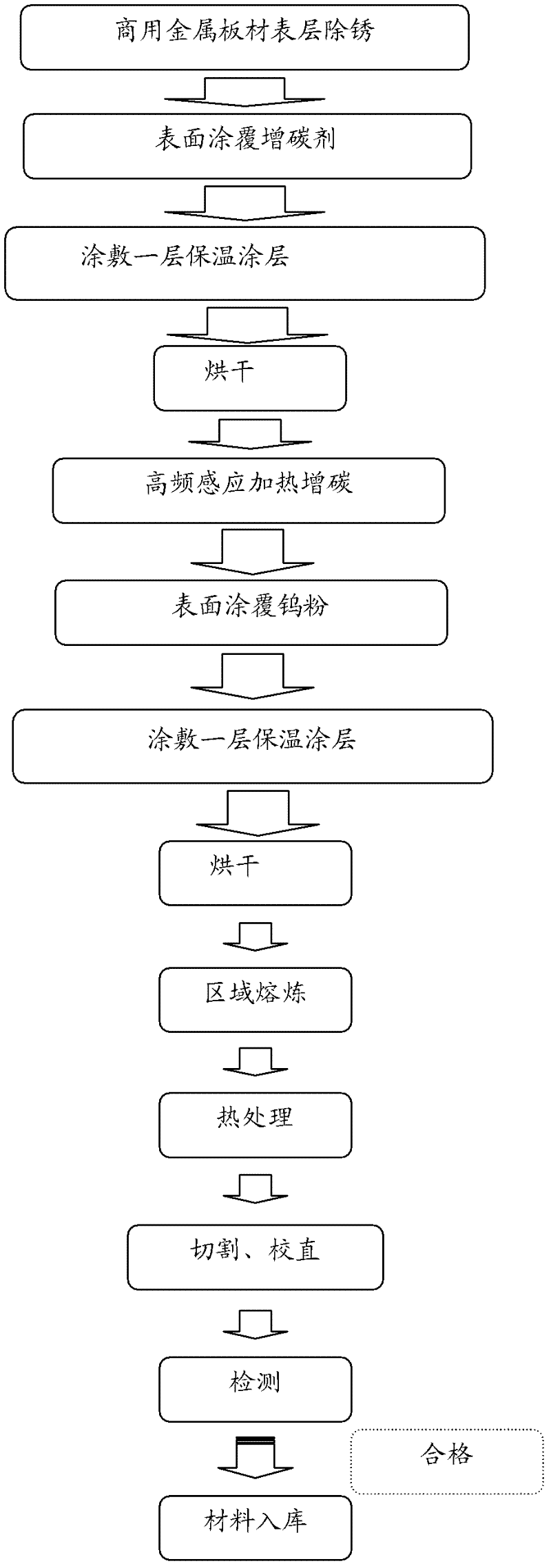

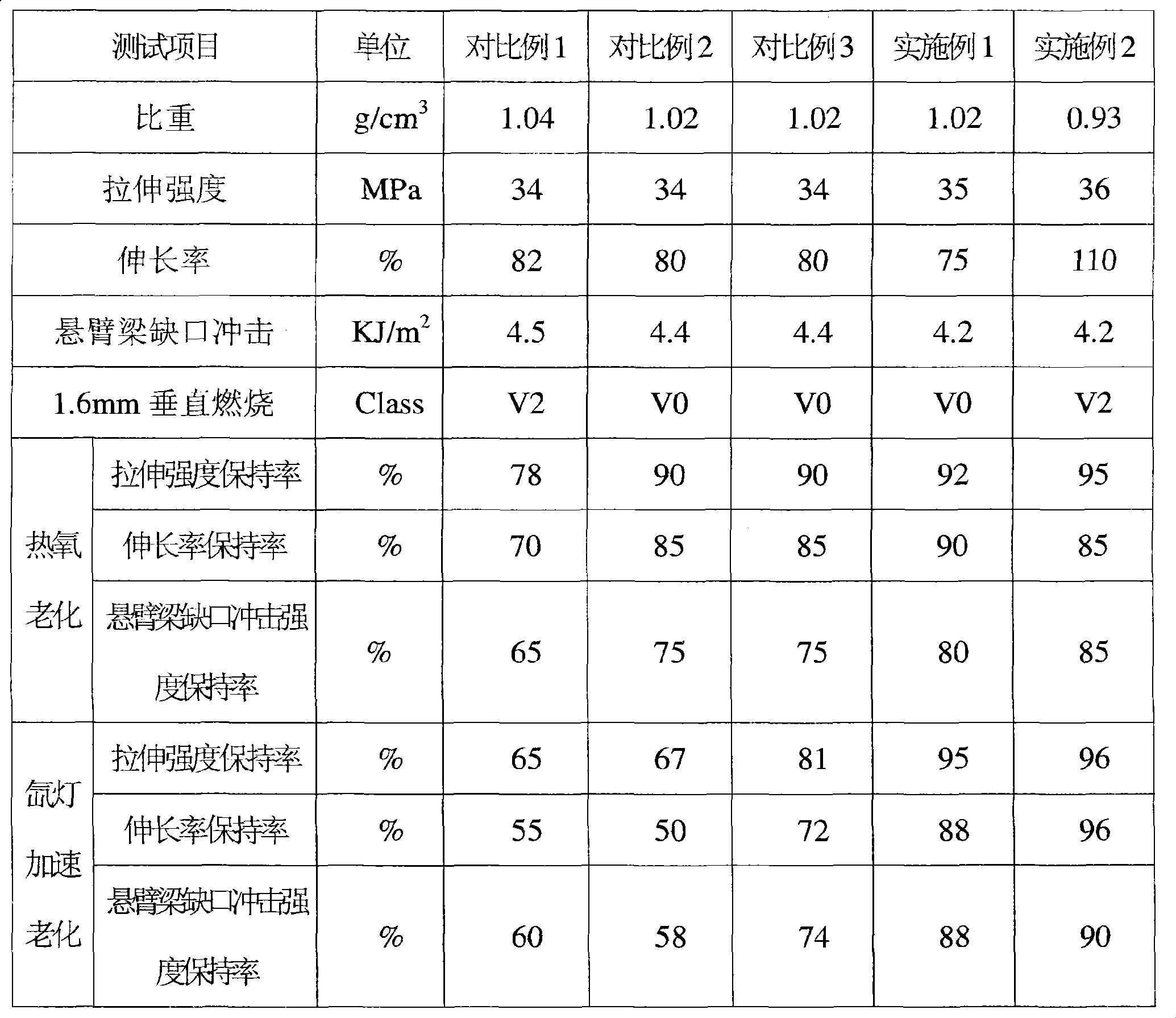

Preparation technology for in-situ synthesis tungsten carbide particle reinforced composite wear-resisting layer on metal plate surface layer

InactiveCN102337536AImprove wear resistanceHigh bonding strengthMetallic material coating processesRustTungsten carbide

The invention discloses a preparation technology for an in-situ synthesis tungsten carbide particle reinforced composite wear-resisting layer on a metal plate surface layer, which comprises the following steps of: carrying out surface rust removal to a metal plate which needs to be subjected to surface layer reinforcement; then, carrying out surface layer recarburization processing on the steel plate; coating metal tungsten powder on the surface of the steel plate; then, coating one layer of heat-insulation coating on the surface of the steel plate coated with the metal tungsten powder; quickly melting the steel plate surface layer by a high-frequency sensor; after the surface layer is solidified, removing the coating layer on the surface layer of the plate material; and finally, obtaining the in-situ synthesis tungsten carbide particle reinforced alloy steel plate material. The alloy steel plate material not only keeps the metal toughness and plastics characteristics of steel plate base material metal but also has higher abrasion resistance. The thickness of the WC (Wolfram Carbide) composite layer can be 1-2mm, and the hardness HRC (Rockwell hardness) is 56-60. The alloy steel plate material has the performances that the alloy steel plate material can deform and can be welded and the like, and the alloy steel plate material can be directly curled, deformed, cut and punched and can be processed by other machining links like the steel plate to be processed into various engineering components (such as pipelines and the like). The in-situ synthesis tungsten carbide particle reinforced composite wear-resisting layer has the advantages of low cost and the like and is easy to industrially produce on a large scale.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

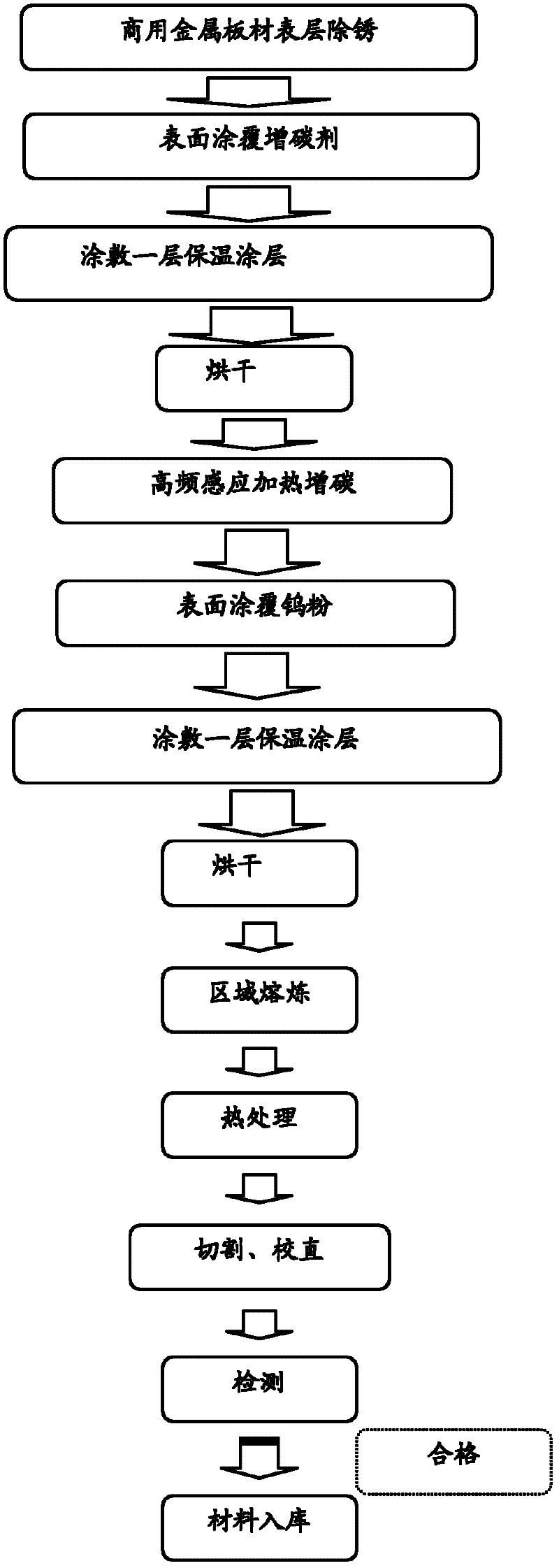

Flame retardant polypropylene resin blend and preparation method thereof

The invention discloses a flame retarding polypropylene resin blend and a preparation method thereof. The flame retarding polypropylene resin blend is prepared according to a weight ratio by 56-90 percent of polypropylene resin, 3-18 percent of flame retardant, 3-6 percent of auxiliary flame retardant, 1-6 percent of flame retarding synergist, 2-8 percent of compatibilizer, 0.5-5 percent of melt strength regulator, 0.1-0.5 percent of antioxidant, 0.1-0.5 percent of heat stabilizer, and 0.3-0.5 percent of light stabilizer. The components are mixed in a high-speed mixer for 2-5 minutes, then extruded by a twin-screw extruder and finally granulated. The flame retarding polypropylene resin blend of the invention can maintain a flame retarding property, and at the same time, has the advantages of low proportion, excellent mechanical property, long thermo oxidative aging, excellent lightfast aging capability, and reduced flame retardant migrating, etc.

Owner:KINGFA SCI & TECH CO LTD +1

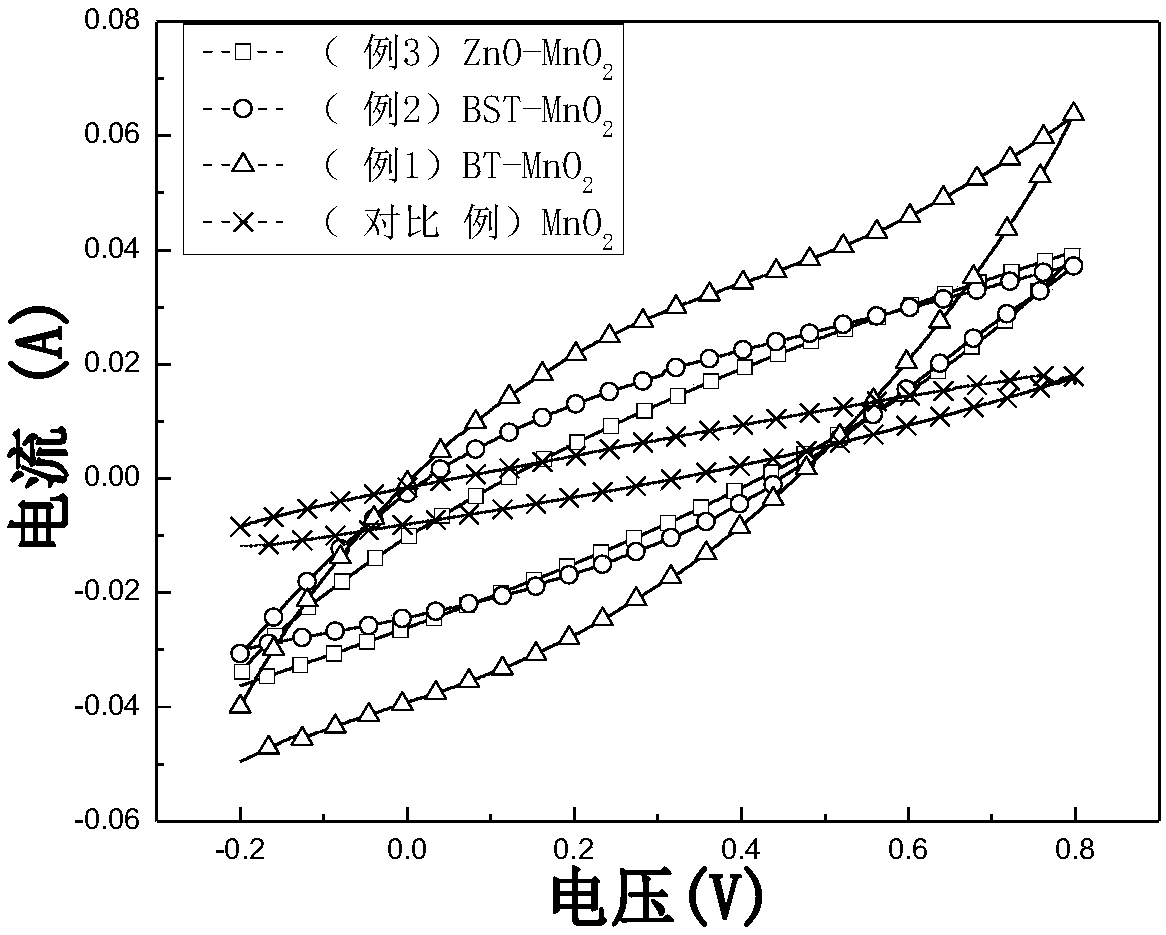

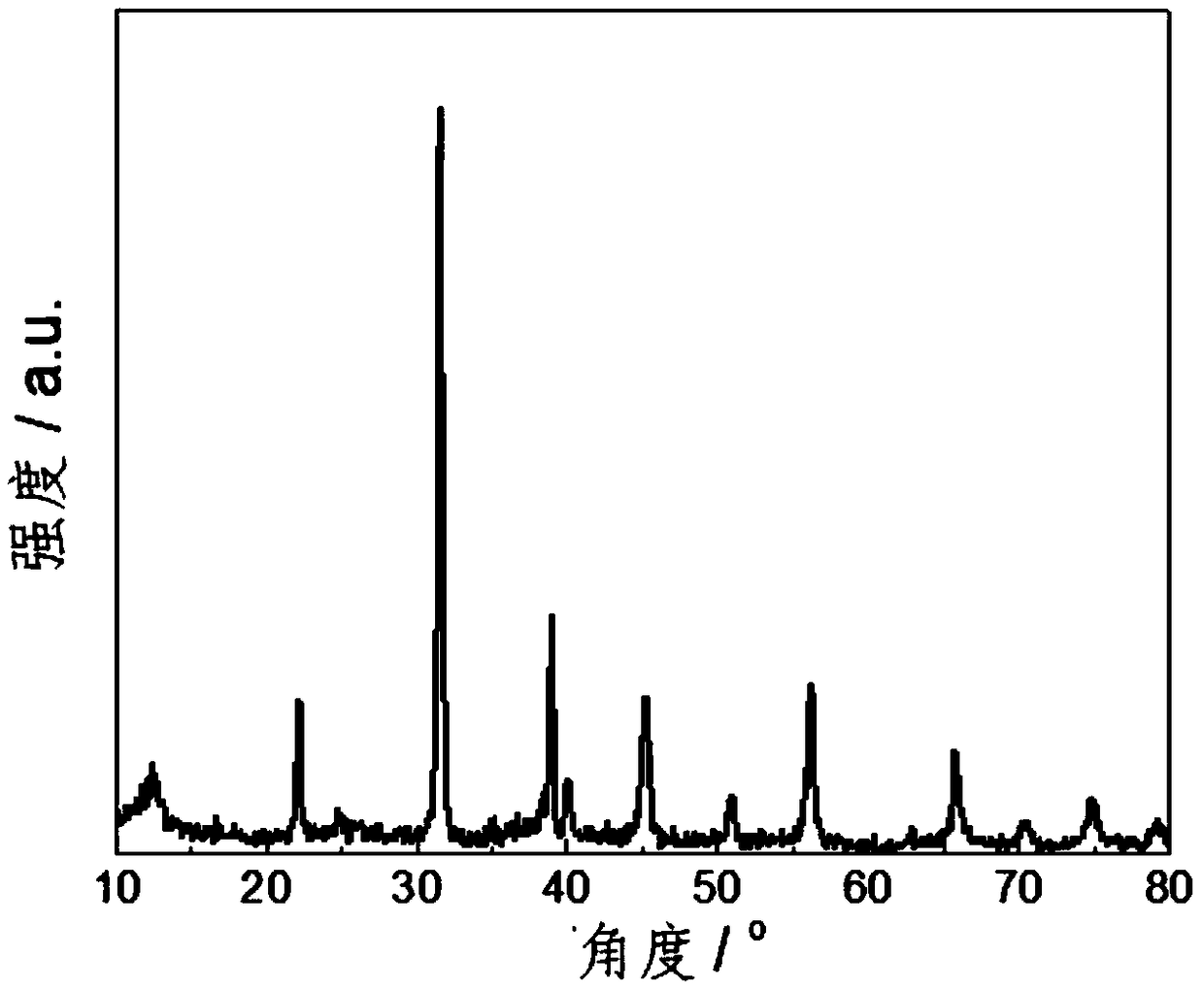

Composite material having pn junction structure for supercapacitor, supercapacitor electrode material and preparation method thereof

InactiveCN108962626AIncrease the resistance valueIncrease working voltageHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceElectrical resistance and conductance

The invention relates to a composite material having a pn junction structure for a supercapacitor, a supercapacitor electrode material and a preparation method thereof. The method is characterized byforming a pn junction between p-type oxide particles and n-type oxide particles by performing a physical or chemical method on p-type semi-conductive oxide powder and n-type semi-conductive oxide powder. The oxide particles having the pn junction can improve the resistance value of a supercapacitor material and can rapidly compensate the insertion charges in a charge / discharge process through thepn junction, thereby avoiding a sharp decrease in the resistance value caused by the introduction of a carbon-related material or metal powders, and greatly increasing the operating voltage and the energy density. Compared with an original p-type oxide (such as MnO2), the composite material obtained by the method of the present invention can increase the specific capacitance in addition to the operating voltage.

Owner:NORTHEASTERN UNIV

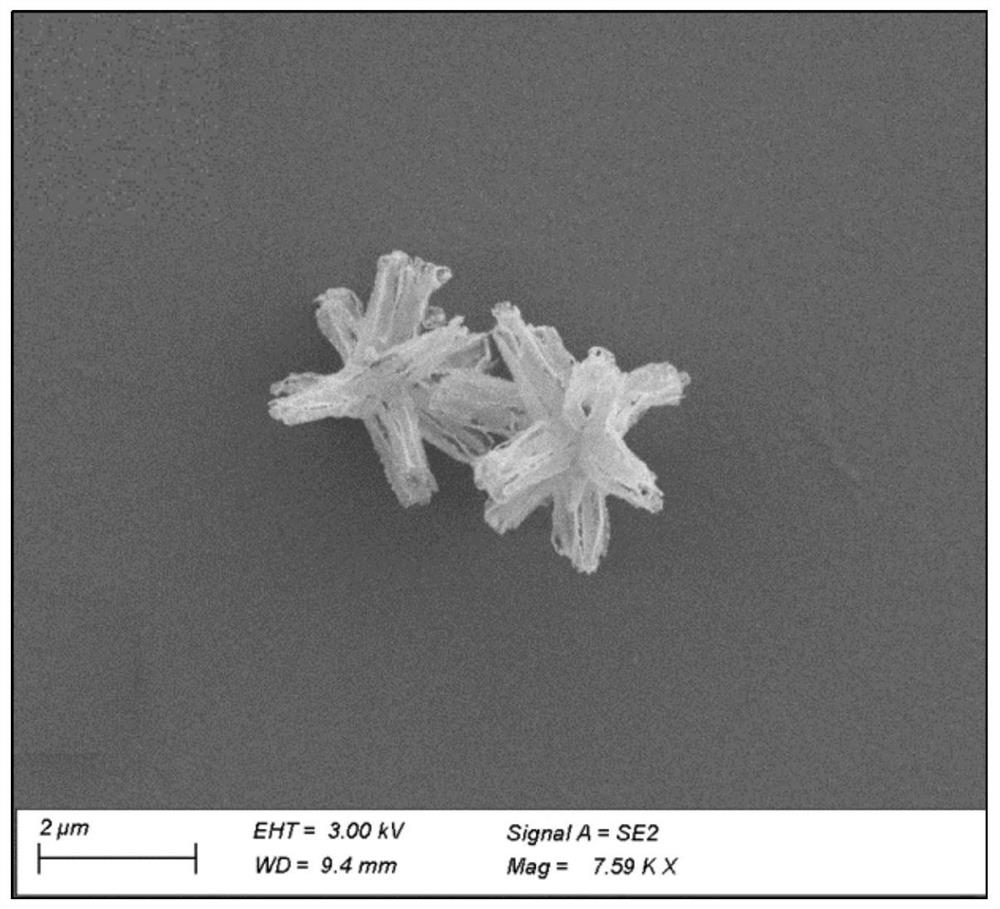

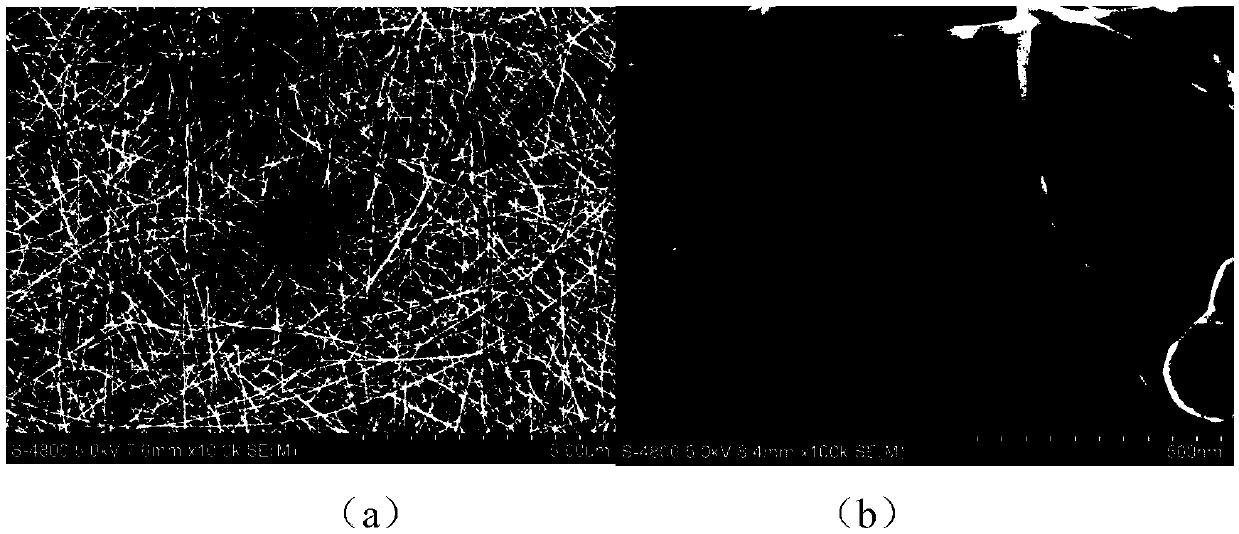

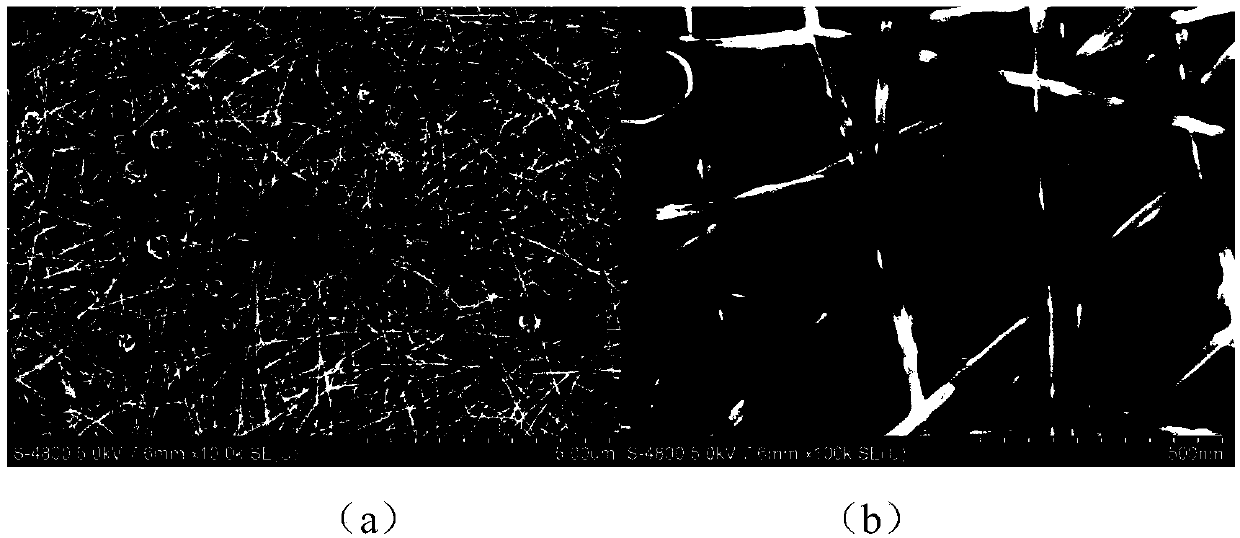

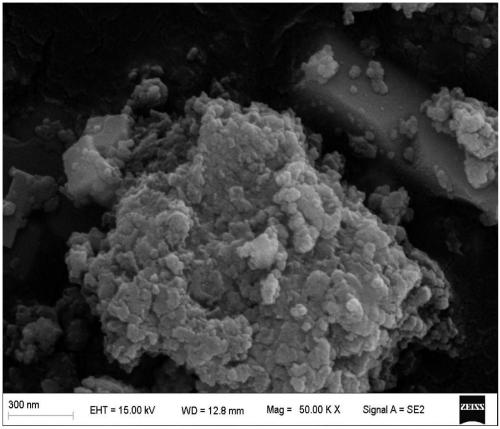

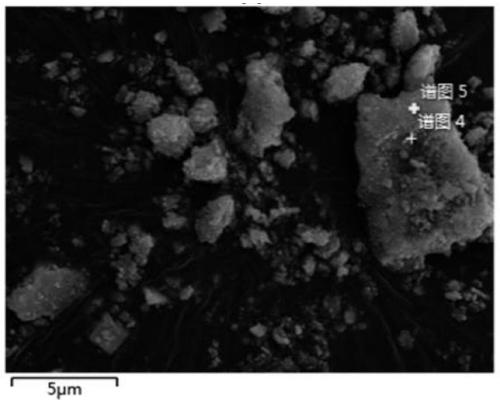

High length-diameter ratio silver nanowire and preparation method thereof

ActiveCN109604630AAvoid damageReduce the number of touch pointsMaterial nanotechnologyTransportation and packagingYield ratioAlkali metal halide

The invention provides a high length-diameter ratio silver nanowire and a preparation method thereof. The preparation method of the high length-diameter ratio silver nanowire comprises the steps thatfirstly ethylene glycol is pretreated, anhydrous magnesium sulfate is added for drying and water removing, the ethylene glycol is obtained to reserve after distilling, silver source AgNO3 is sieved through a sieve, and fine powder is obtained to used as a reaction silver source; in the reaction, by adding two alkali metal halide salts, the formation of silver particles is prohibited in the reaction, the yield is improved, the amount of PVP and the temperature gradient and rotation speed in the reaction are accurately controlled, and the wire length and the wire diameter of silver wire are controlled; the whole reaction is carried out under the condition of an environmental humidity of 30-60%, and the ultrafine silver nanowire with an average wire diameter of about 25nm, a wire length of about 40 <mu>m and a length-diameter ratio of up to 1500 can be obtained. The preparation method has simple operation, less by-products, high yield ratio and good repeatability, successfully amplified to 14L reaction is carried out, so that large-scale industrial production is extremely easy.

Owner:SHAANXI COAL & CHEM TECH INST

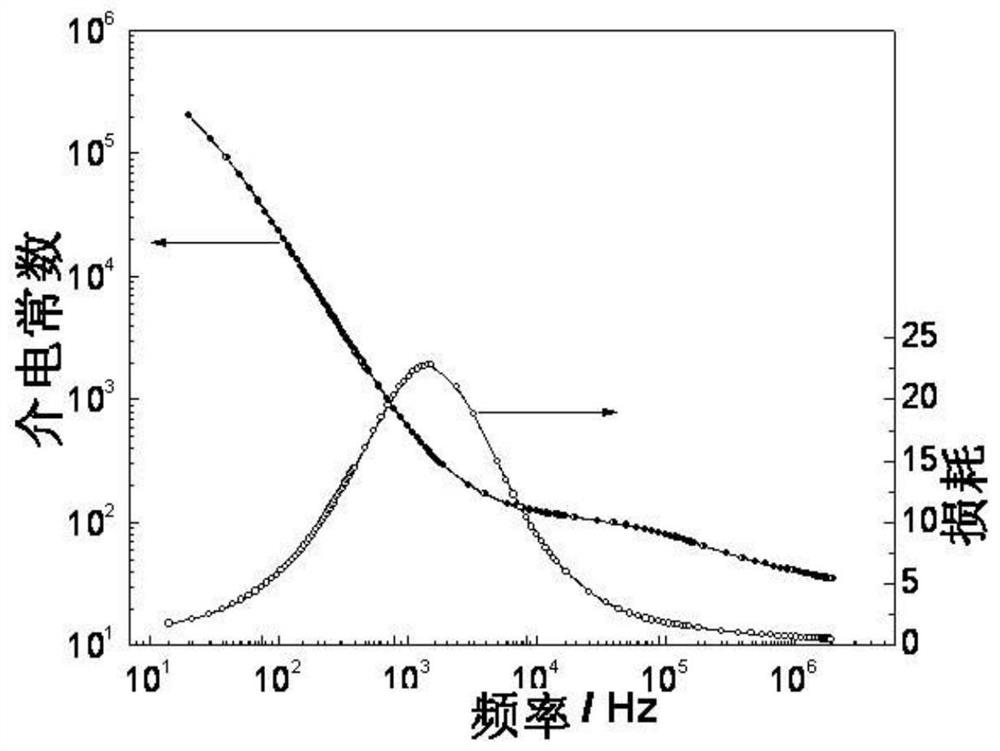

Composite material with ultra-high dielectric constant, and preparation method and application thereof

InactiveCN109003821AEasy to operateLow priceAlkaline earth titanatesZinc oxides/hydroxidesDielectricOxide composite

The invention relates to a novel ultra-high dielectric constant composite material, and a preparation method and application thereof, the composite material is an oxide composite material formed by ann-type semiconducting metal oxide with a pn junction and a p-type semiconducting metal oxide, and the relative dielectric constant thereof is 105 or more. The invention also provides a preparation method of the ultra-high dielectric constant composite material, a physical or chemical method is applied to p-type semiconducting metal oxide powder and n-type semiconducting oxide powder, the pn junctions are formed between p-type oxide particles and n-type oxide particles, and the oxide particles with the pn junctions are pressed or sintered to form a novel composite material with an ultra-high dielectric constant.

Owner:NORTHEASTERN UNIV

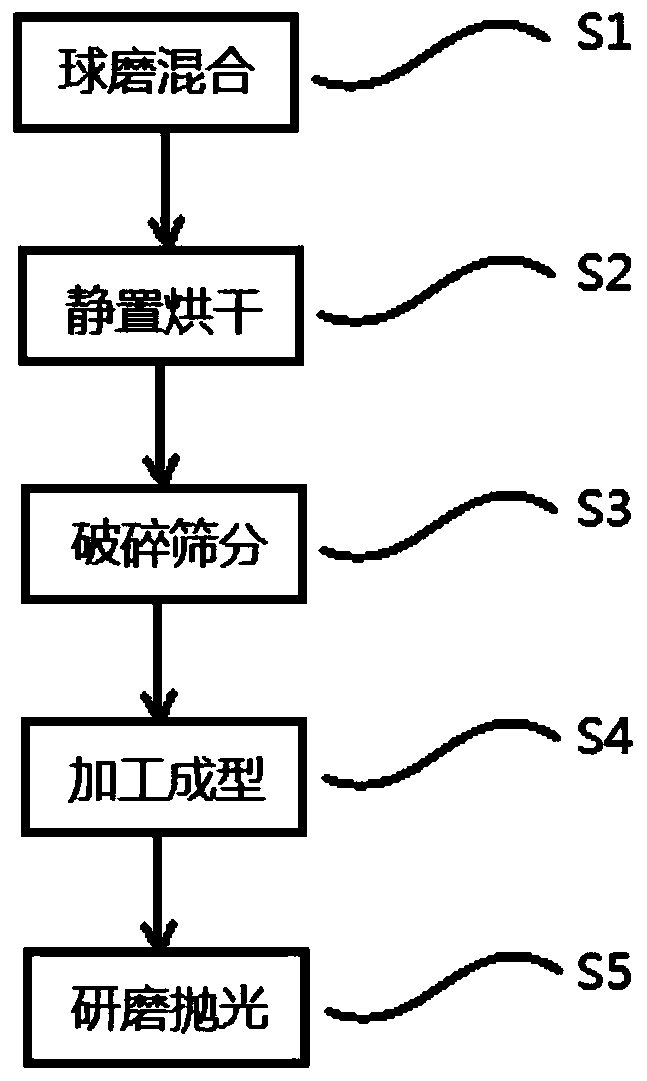

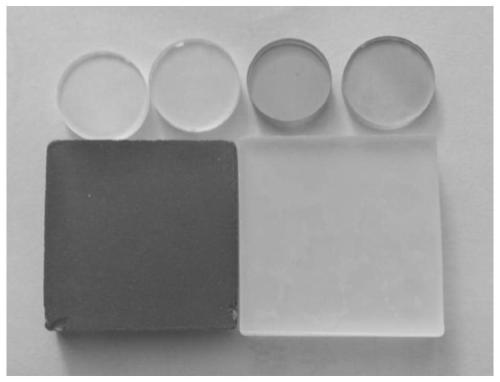

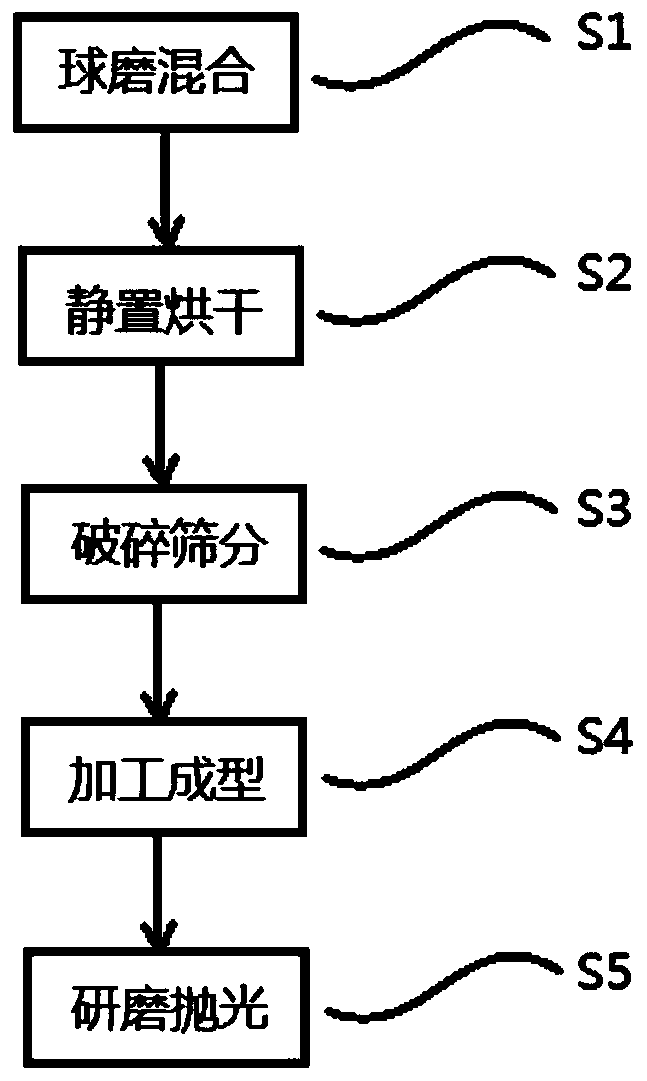

Preparation method of transparent ceramic

InactiveCN110183223AImprove the sintering processGood optical performanceBall millHot isostatic pressing

The invention discloses a preparation method of a transparent ceramic. The preparation method includes the following steps: to-be-obtained transparent ceramic powder and a sintering assistant are fully mixed through a planetary ball milling process; after ball milling is performed for a given time, drying is performed; the dried powder is pulverized and screened, and then sequentially subjected toprepressing, cold isostatic pressing, high temperature sintering and grinding / polishing steps; a transparent ceramic sample is obtained through preparation. Through the preparation method of the invention, the compound sintering assistant is adopted to effectively promote the sintering process of the ceramic; the sintering temperature is reduced; the transparency of the transparent ceramic is increased.

Owner:深圳市丁鼎陶瓷科技有限公司

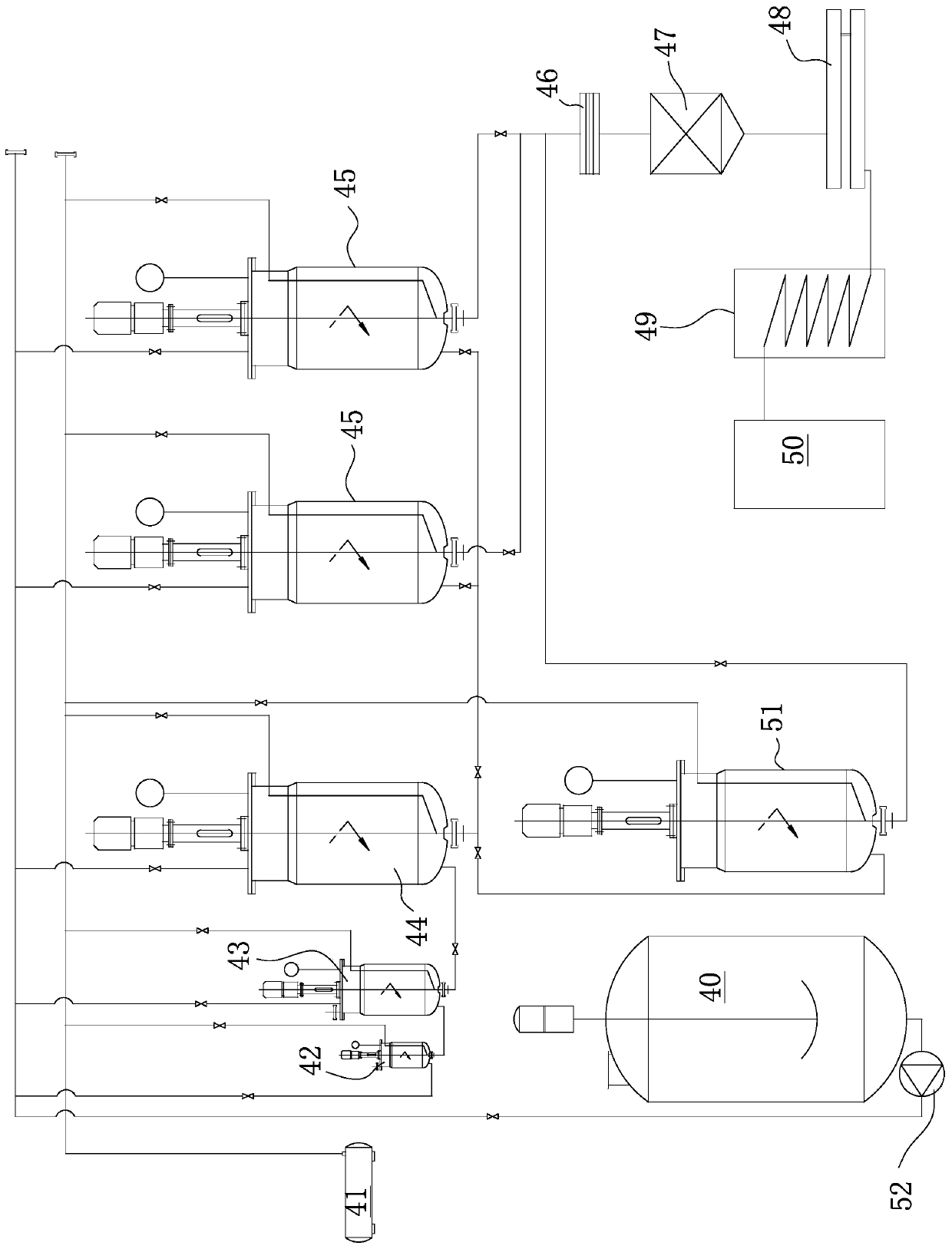

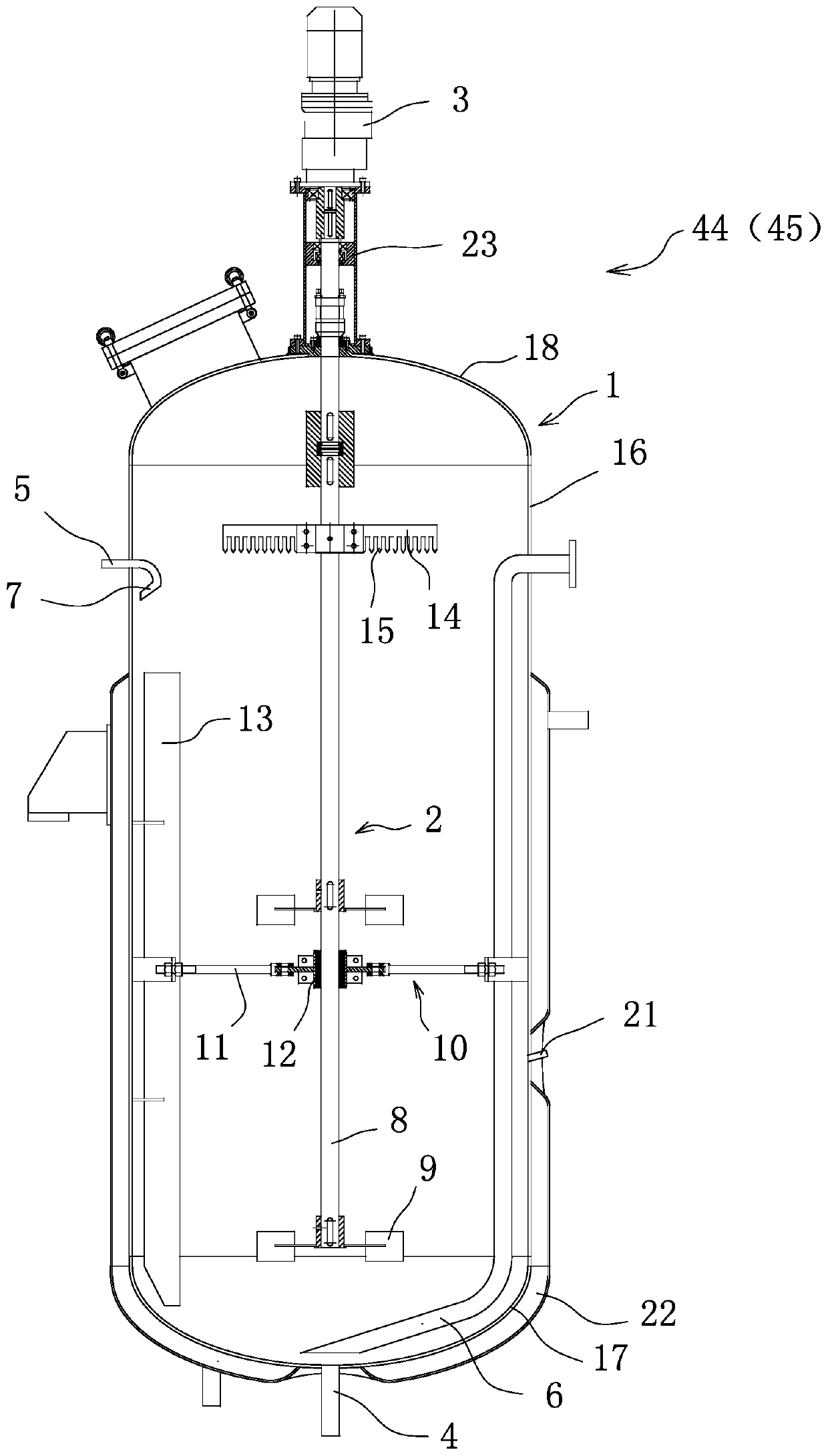

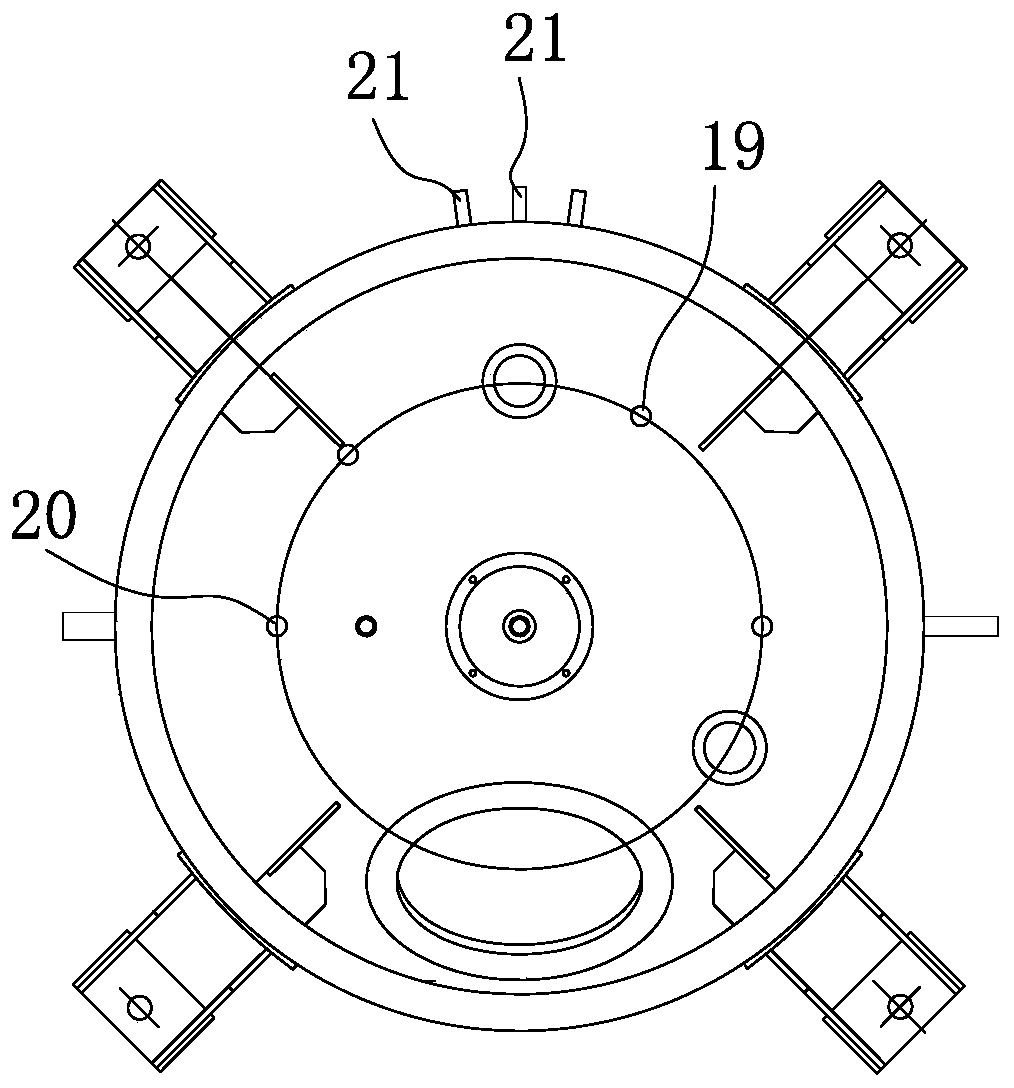

Semi-continuous black-tea fungus fermentation broth preparation method and apparatus

PendingCN110892928APrevents the phenomenon of bacterial cellulose film formationReduce generationPre-extraction tea treatmentBiotechnologyContinuous fermentation

The invention belongs to the technical field of food, and discloses a semi-continuous black-tea fungus fermentation broth preparation method and apparatus. The preparation method comprises a culture liquid preparation step, an expanding culture step, and a fermentation tank fermentation step, and further comprises a semi-continuous fermentation step, wherein the semi-continuous fermentation step is that a part of a black-tea fungus fermentation raw liquid after the fermentation tank fermentation step is discharged from the fermentation tank, and is subjected to subsequent inactivation, filtration, concentration and filling steps, and a sterilized sugar tea soup is supplemented into the tank after a part of the black-tea fungus fermentation raw liquid is discharged from the original fermentation tank, so that the remaining black-tea fungus fermentation raw liquid in the original fermentation tank is used as a seed liquid to perform continue fermentation. The method utilizes a stepwise amplification dynamic fermentation mode, and the disadvantages of long process time and relatively large flavor difference between batches of static fermentation of black-tea fungus are avoided.

Owner:ZHEJIANG MINGHUANG NATURAL PRODS DEV

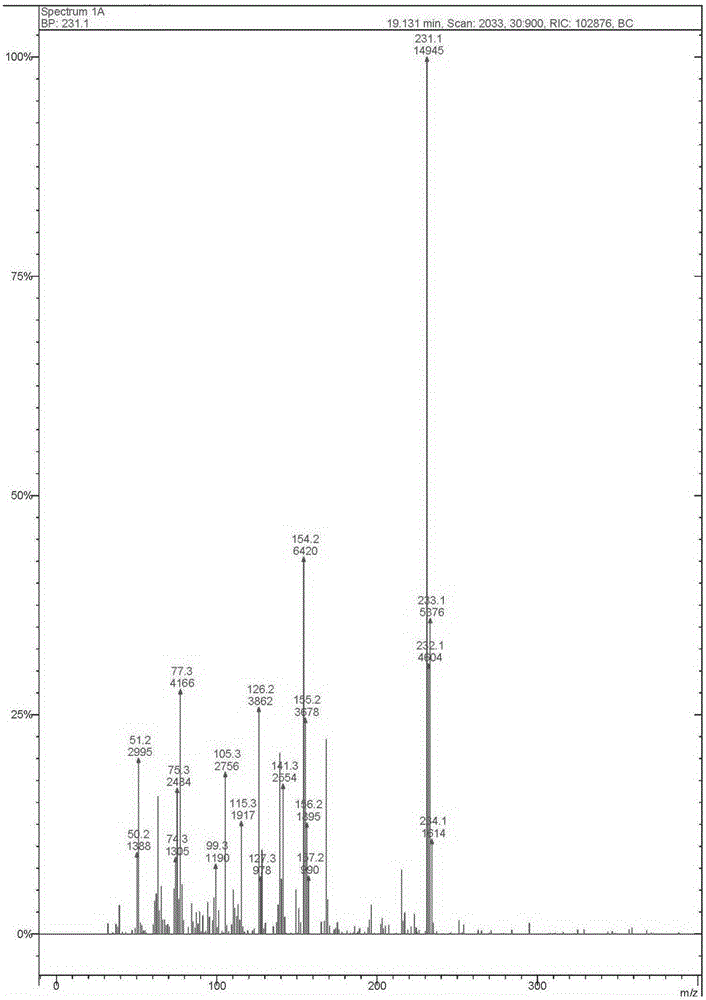

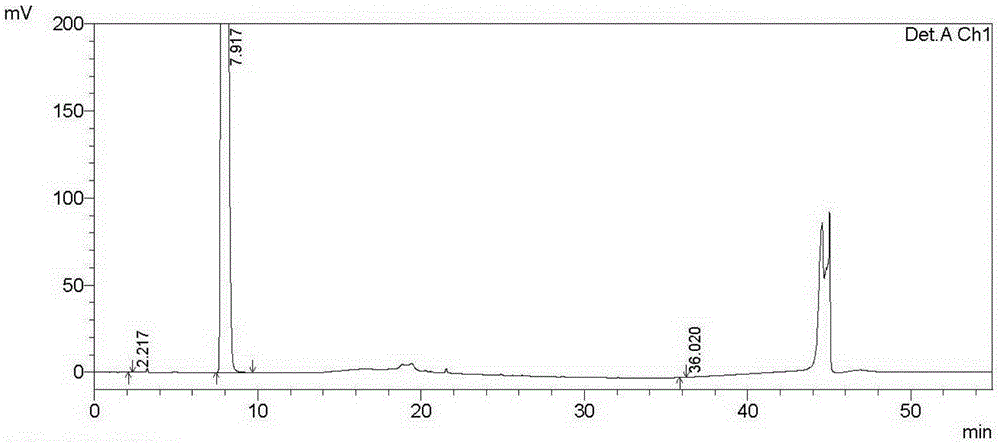

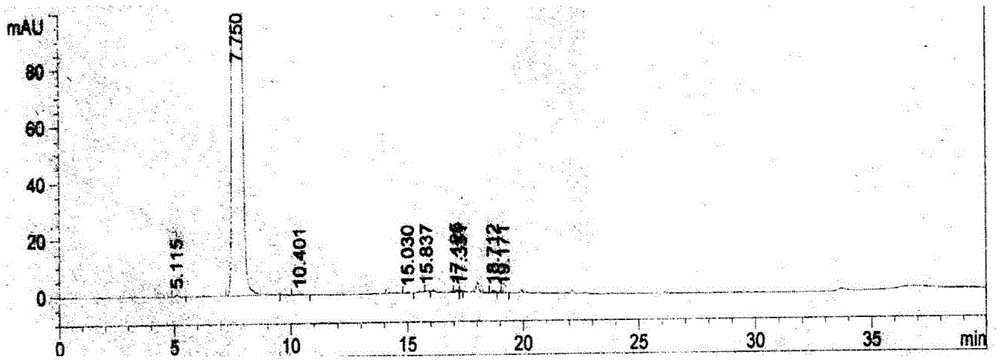

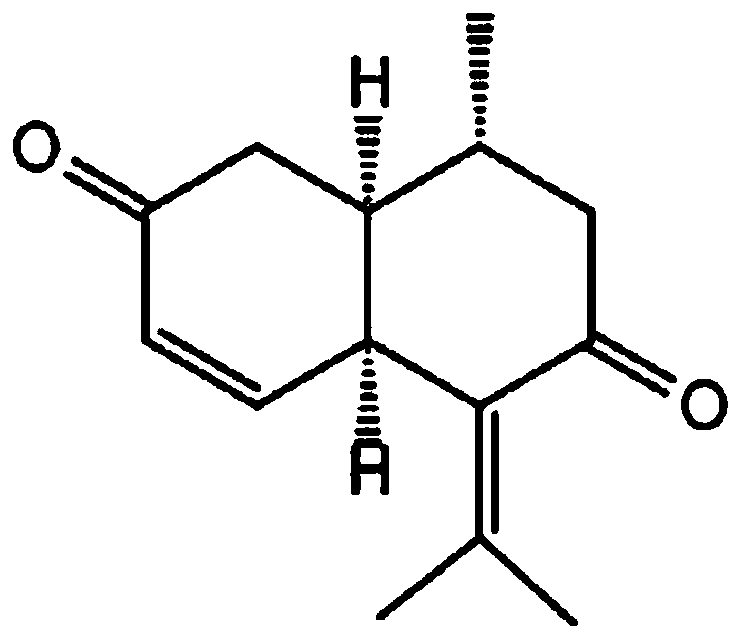

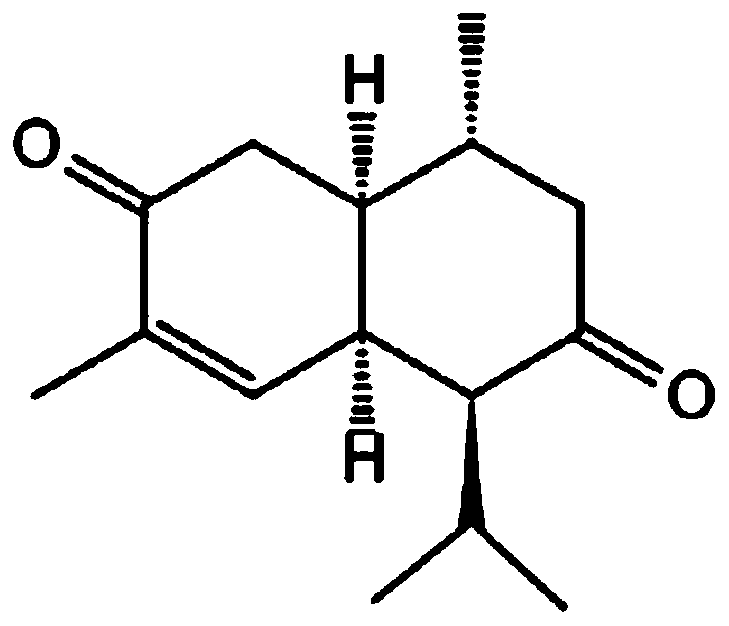

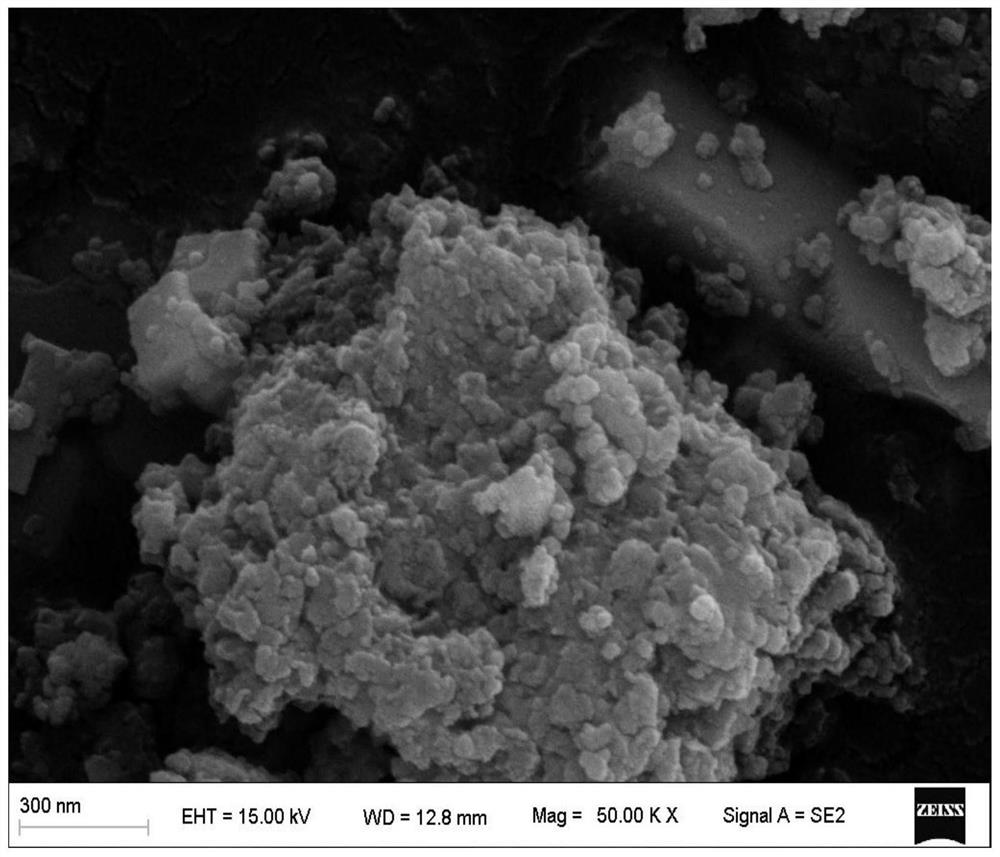

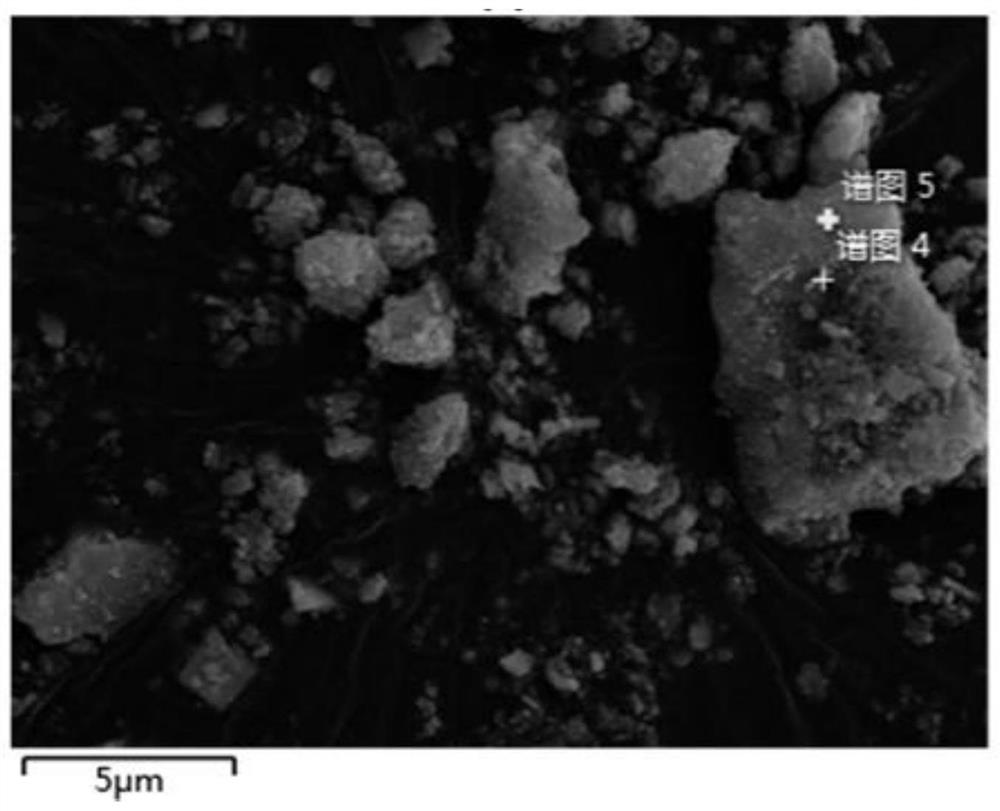

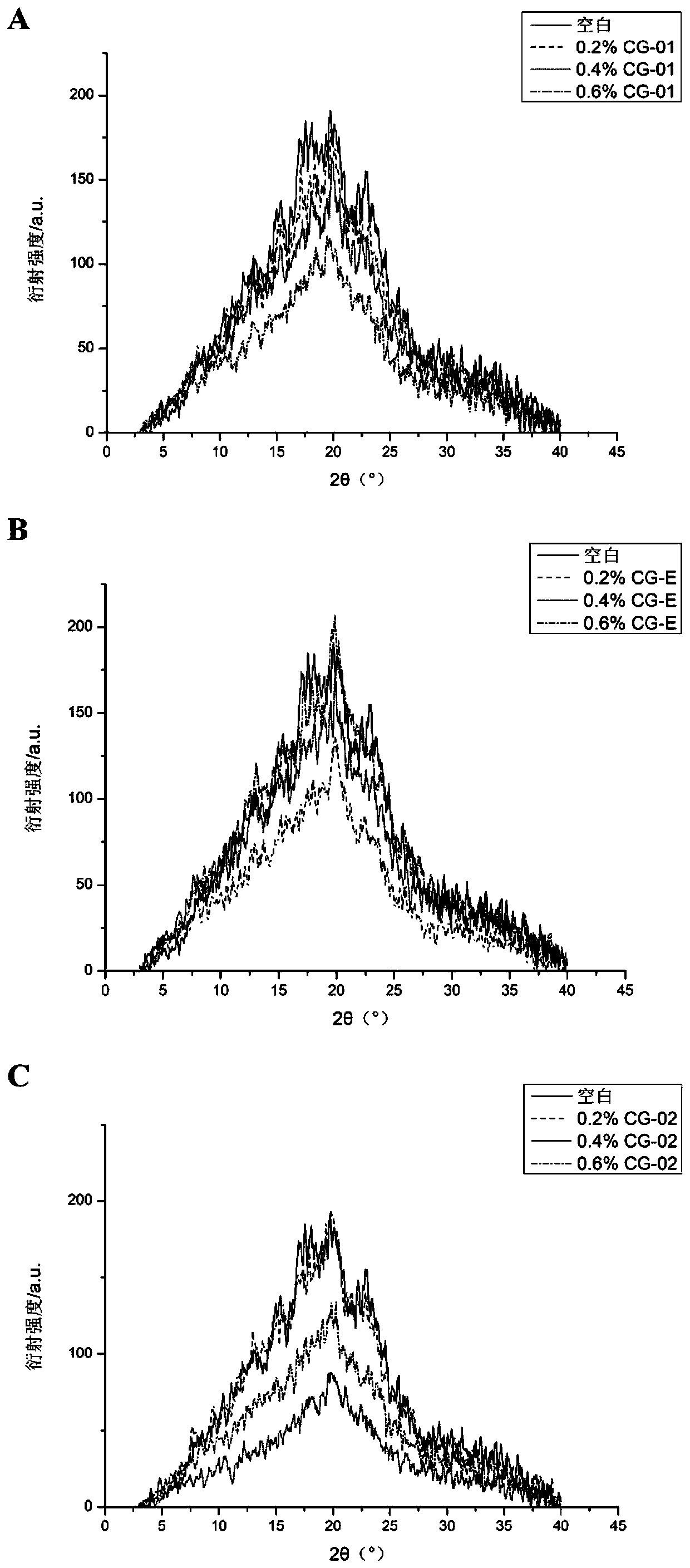

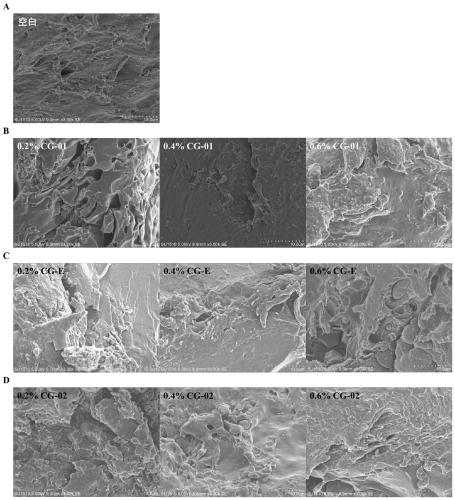

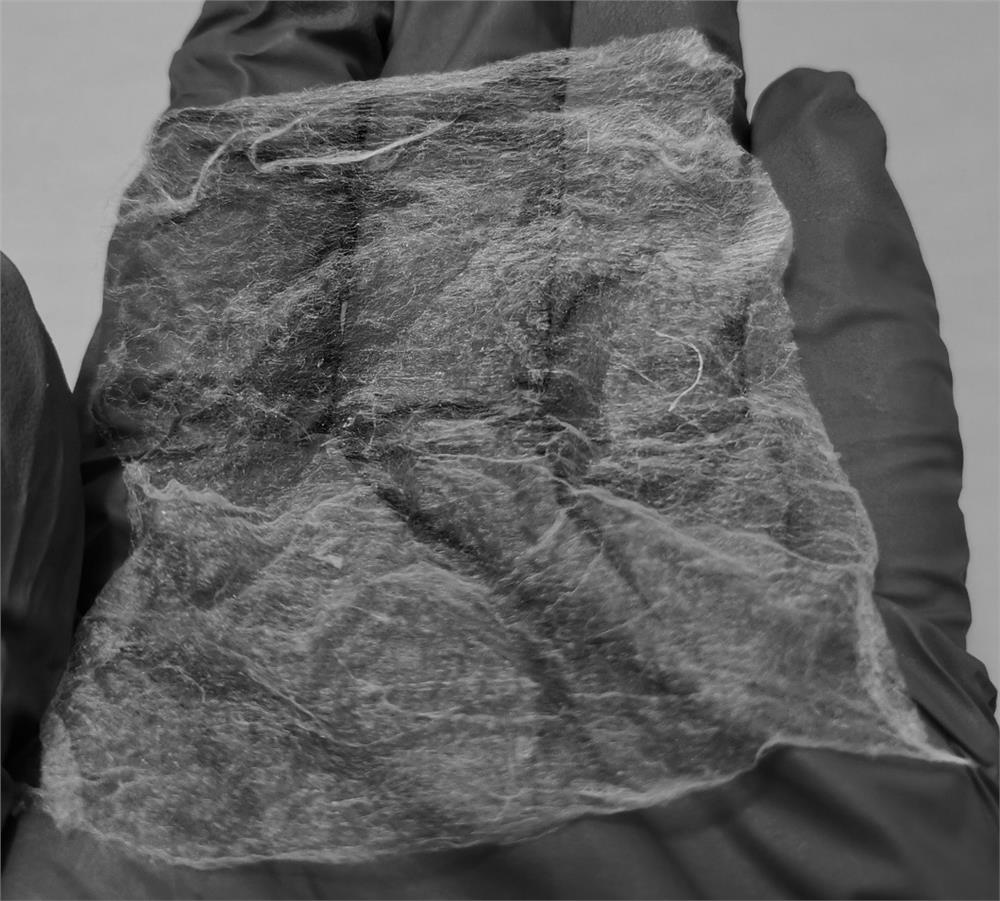

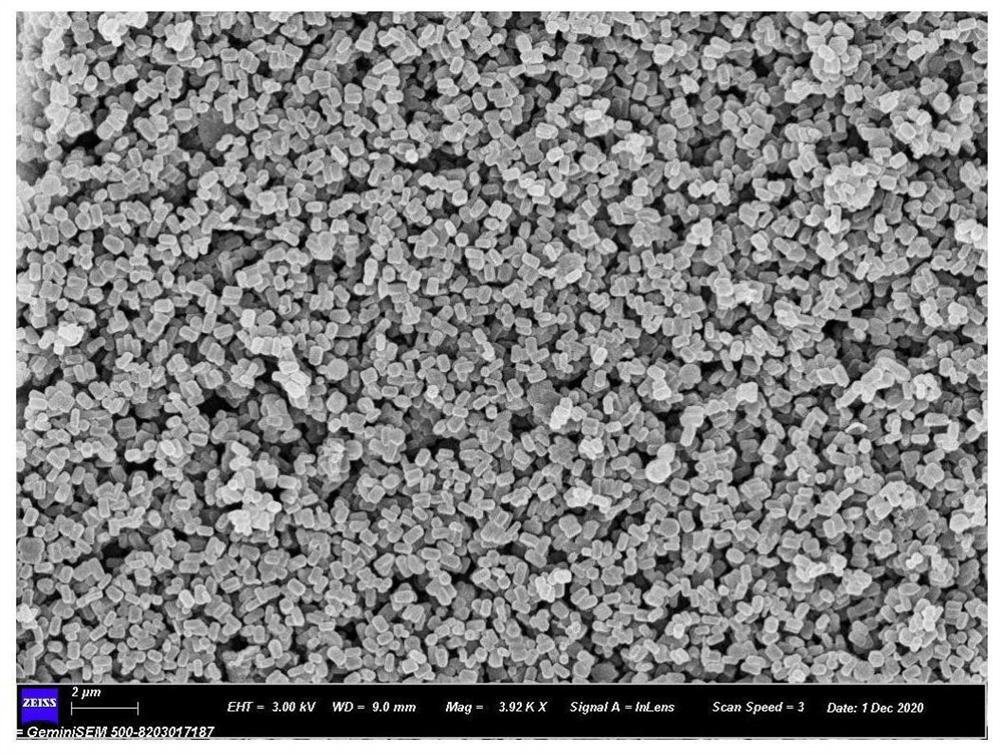

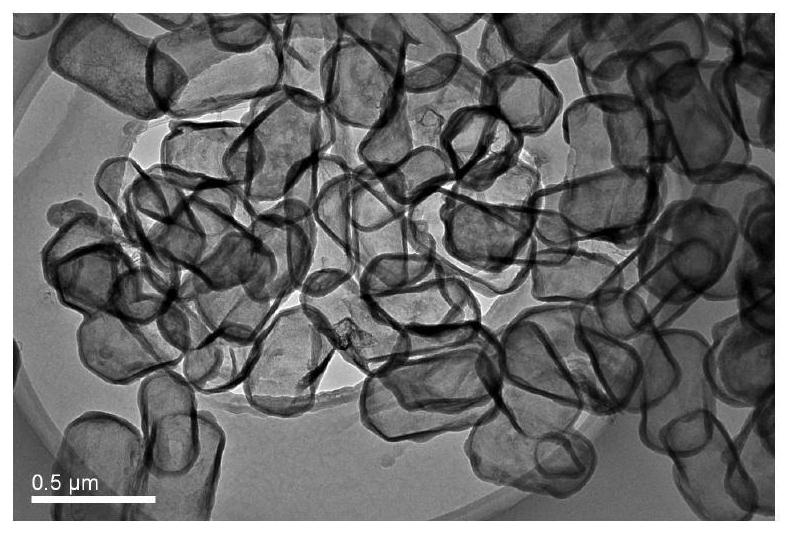

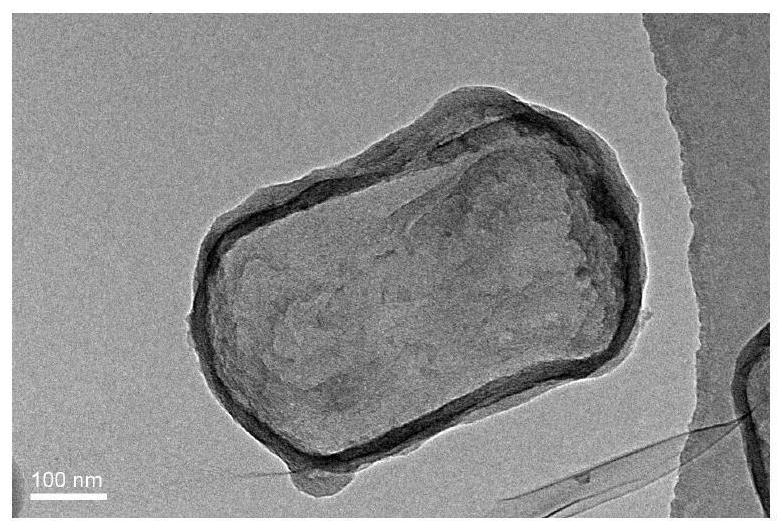

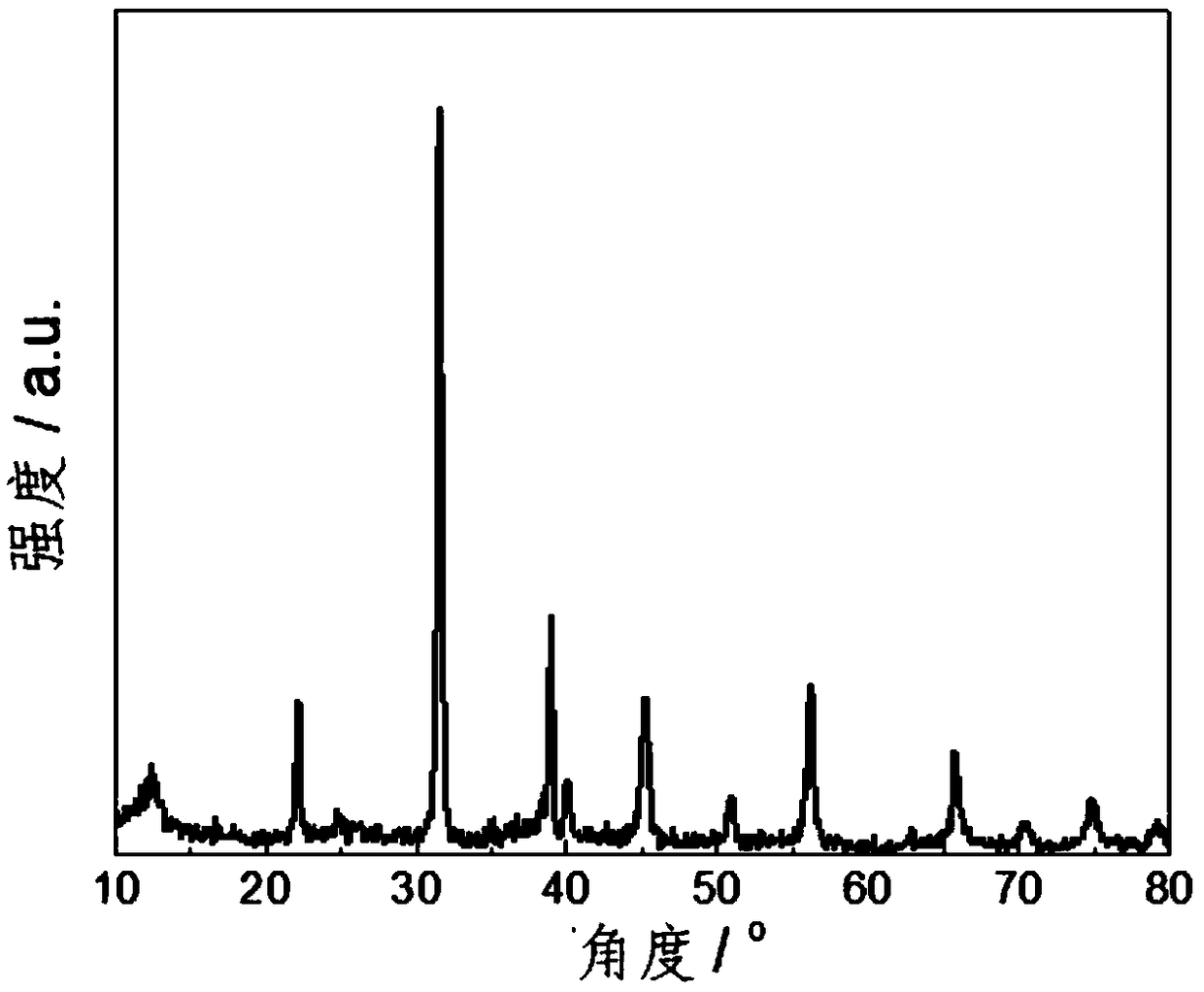

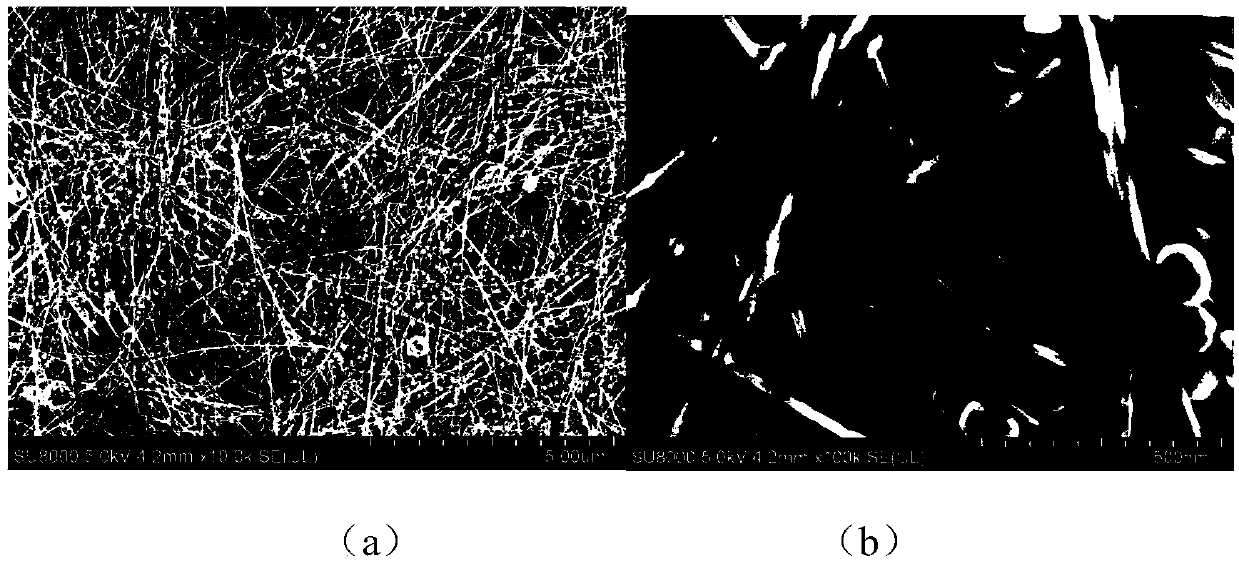

Calix[4]arene adenine derivative-oxidized graphene compound, preparation method and applications thereof

InactiveCN105823764ASimple manufacturing processEase of industrial production in large quantitiesFluorescence/phosphorescencePhotochemistryParticle suspension

The invention relates to a calix[4]arene adenine derivative-oxidized graphene compound, a preparation method and applications thereof. The compound is formed by connecting oxidized graphene and calix[4]arene adenine derivatives through amido bonds. The preparation method comprises the following steps: (1) subjecting oxidized graphene to chloroformylation; (2) dissolving excess calix[4]arene adenine derivatives by an organic solvent, adding chloroformylated oxidized graphene powder, stirring for 6 to 96 hours at a room temperature to obtain a black particle suspension liquid, carrying out centrifugal separation, carrying out saturated salt water washing, adding distilled water, carrying out centrifugal separation, and drying to obtain black powder namely the calix[4]arene adenine derivative-oxidized graphene compound, which can be used to recognize, combine, and stabilize cancer gene promoter region G-quadrome. Compared with the prior art, the preparation technology is simple and easy to perform, and a novel method is provided to detect G-quadrome through biological macro-cycle molecules.

Owner:TONGJI UNIV

Color transparent ceramic and preparation method thereof

InactiveCN110204327AImprove the sintering processLower sintering temperatureColoring agentsTransparent ceramics

The invention discloses a color transparent ceramic and a preparation method thereof. The preparation method comprises: completely mixing the power of a to-be-obtained color transparent ceramic, a coloring agent and a sintering aid by using a planetary ball milling process, carrying out ball milling for a predetermined time, drying, carrying out breaking screening on the dried powder, and sequentially carrying out pre-pressing molding, cold isostatic pressing treatment, high-temperature sintering and grinding / polishing to prepare the color transparent ceramic sample. According to the present invention, the color transparent ceramic can be prepared; by using the composite sintering aid, the sintering process of the ceramic is effectively promoted, the sintering temperature is reduced, and the light transmittance of the transparent ceramic is improved; and the preparation process is simplified by adding the coloring agent at one time.

Owner:深圳市丁鼎陶瓷科技有限公司

Preparation method of doped tin oxide transparent conducting film

InactiveCN106158997AHigh light transmittanceReduce sheet resistanceFinal product manufacturePhotovoltaic energy generationSolar cellHYDROSOL

The invention relates to a preparation method of a doped tin oxide transparent conducting film. Square resistance of a tin oxide transparent conducting film is reduced through a multi-element doping synergistic effect; a chemical composition of the doped tin oxide transparent conducting film formed by multi-element doping is as follows: Sn1-ySbyO2-xFxPz, wherein x is equal to 0.1 to 0.8, y is equal to 0.02 to 0.2 and z is equal to 0.02 to 0.2. A preparation process comprises six steps: coating a glass substrate with a silicon dioxide transition layer, preparing phosphorus-doped tin oxide nano sol, preparing a phosphorus-doped tin oxide gel film, filling a porous gel film with antimonic fluoride, sintering a multi-element-doped gel film at a high temperature and forming the dense transparent conducting film. The multi-element-doped tin oxide transparent conducting film provided by the invention has high light transmittance and low square resistance and can be used as a large-area film solar cell transparent electrode.

Owner:TIANJIN VOCATIONAL INST

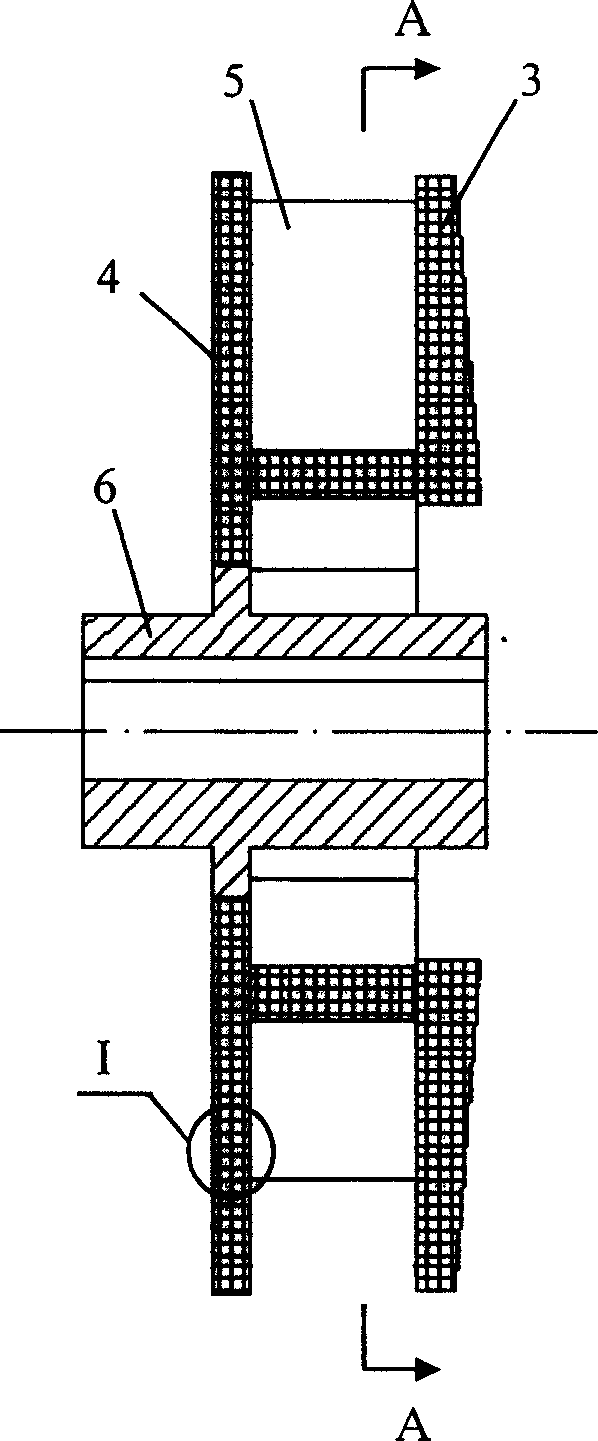

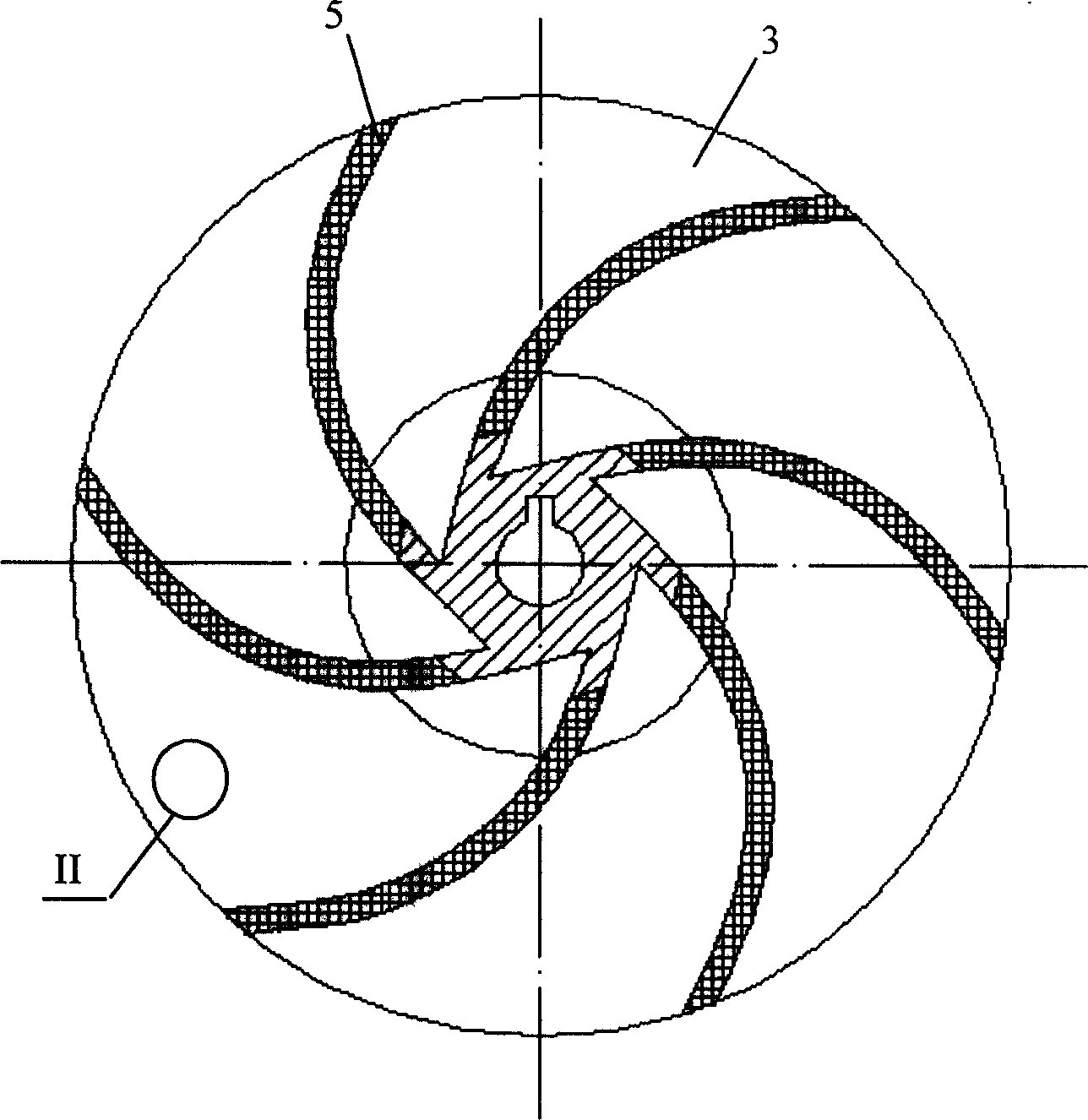

Nano structure metal screen-polyurethane composite anti-wear impeller and its preparing process

InactiveCN1648461AHigh strengthImprove toughnessSpecific fluid pumpsPump componentsImpellerPolyurethane elastomer

The impeller consists of front cover plate, back cover plate, blades and hub. The front cover plate, the back cover plate and the blades fixed on the hub are made of closely laminated nanometer structure metal screen and polyurethane composite material. The present invention has the advantages of high anti-cracking strength, lowered polyurethane consumption and low production cost. The polyurethane elastomer fixes and protects the nanometer structure metal screens against medium corrosion to result in high integral strength, high wear resistance, excellent damping performance and long service life.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Synthetic method of 2-amino-4-(ethylsulfonyl) phenol

ActiveCN105566182AEnhanced carbon bond activityHydrolysis reaction is easy to occurOrganic chemistryOrganic compound preparationSolventChemistry

The invention provides a synthetic method of 2-amino-4-(ethylsulfonyl) phenol. The method comprises the following steps that firstly, 4-ethylsulfonyl-2-nitro-chlorobenzene and alkali are subjected to a reaction in a solvent to obtain 4-(ethylsulfonyl)-2-nitro-phenol; then, the 4-(ethylsulfonyl)-2-nitro-phenol obtained in the last step is reduced to obtain 2-amino-4-(ethylsulfonyl) phenol. The novel synthesis route is designed, no high temperature or high pressure is needed in the reaction process, reaction conditions are mild, and the reaction yield and product purity are high, so that the production cost of the product is lowered, the product quality is improved, the preparation technology is more reasonable, and large batch industrial production is facilitated.

Owner:苏州正济药业有限公司

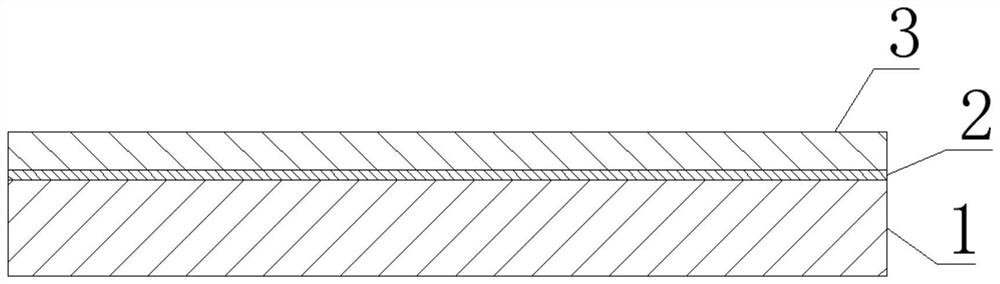

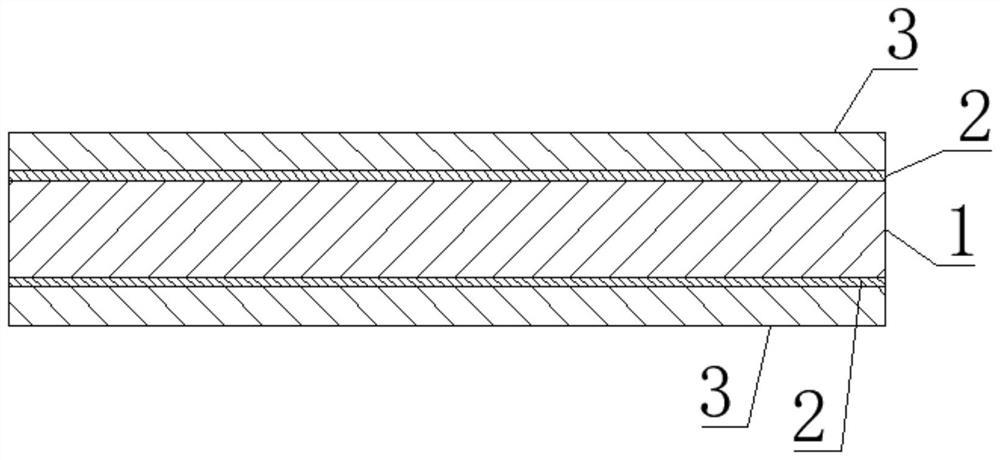

Thermal self-closing ceramic modified diaphragm and preparation method thereof

PendingCN111816823AStop passingHas thermal self-closing propertiesSecondary cellsCell component detailsCoated surfacePolyolefin

The invention discloses a thermal self-closing ceramic modified diaphragm and a preparation method thereof, and belongs to the technical field of lithium battery diaphragms, the thermal self-closing ceramic modified diaphragm comprises a polyolefin diaphragm substrate, at least one surface of the polyolefin diaphragm substrate forms a corona treatment surface, and the corona treatment surface is coated with a thermal self-closing ceramic coating. The invention discloses a preparation method of a thermal self-closing ceramic modified diaphragm. The method comprises the following steps: S1, preparing a thermal self-closing ceramic coating, S2, unwinding the polyolefin diaphragm base material; S3, carrying out corona treatment on the coated surface of the polyolefin diaphragm base material; after corona treatment is finished, coating the thermal self-closing ceramic coating prepared in the step S1; and S4, drying and shaping the coated polyolefin diaphragm base material; and S5, after drying is completed, conducting rolling, conducting standing and curing for 6-8 days at the normal temperature, and obtaining the thermal self-closing ceramic modified diaphragm. The thermal self-closingceramic modified diaphragm and the preparation method thereof have the advantages that the thermal self-closing performance is achieved, the safety is improved, the thermal curing performance is achieved, and the diaphragm breaking temperature is increased.

Owner:联景(厦门)信息技术有限公司

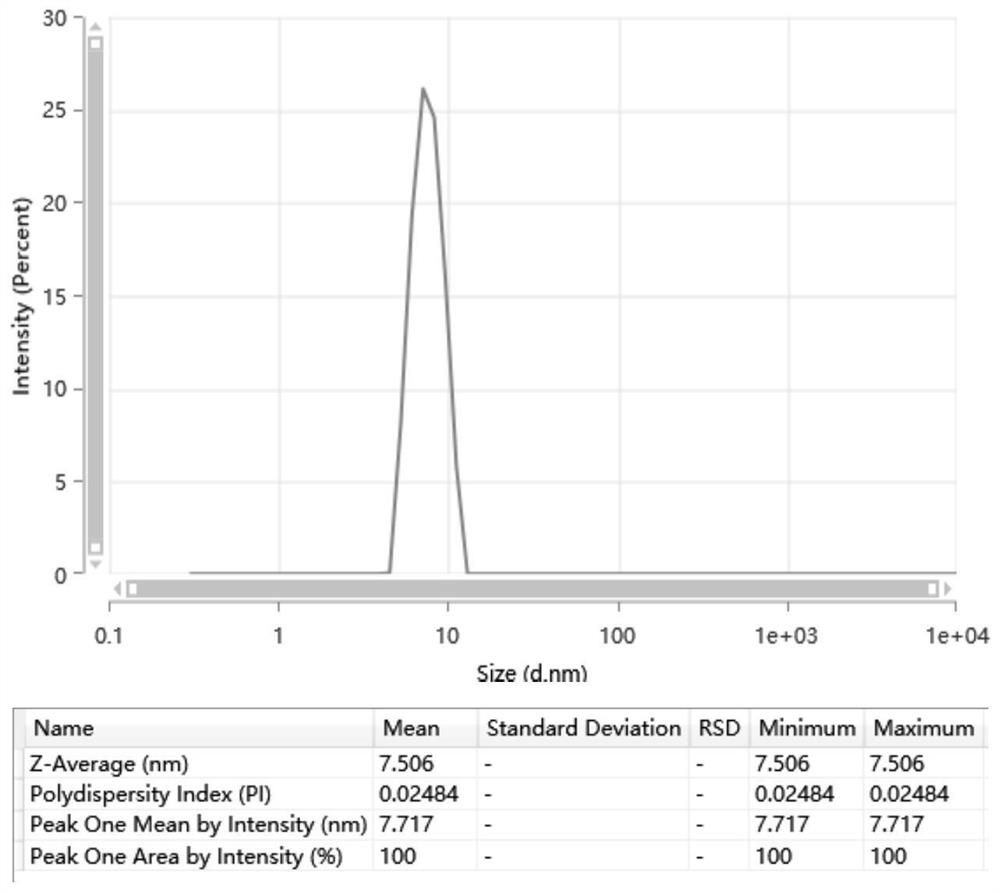

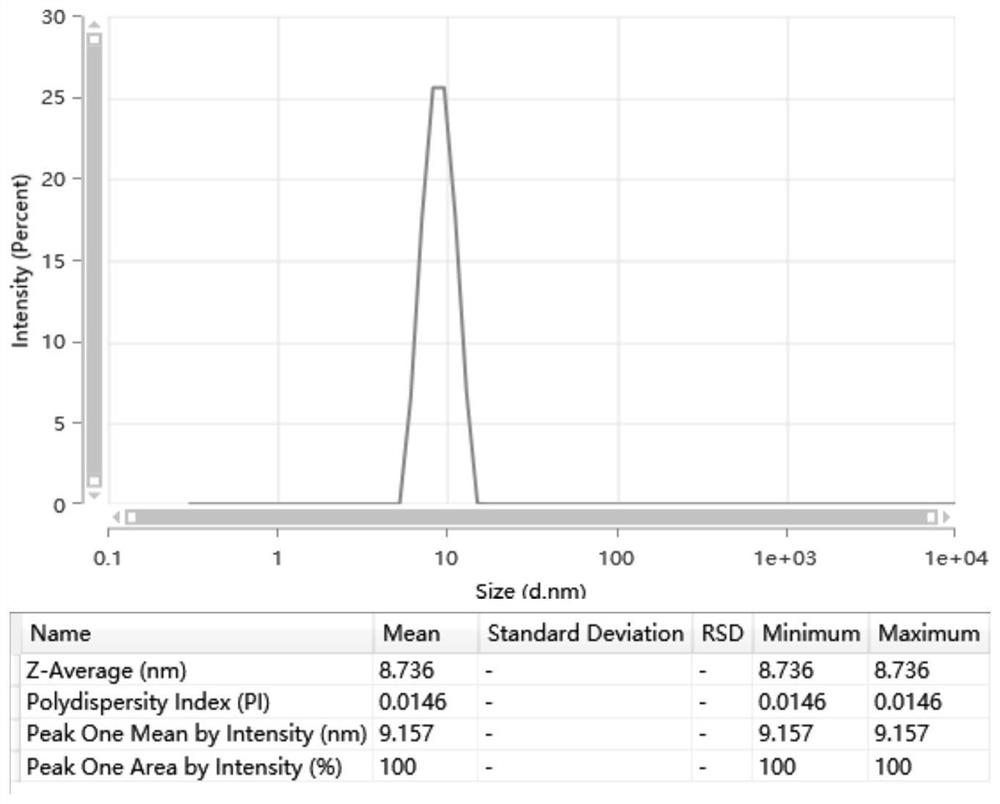

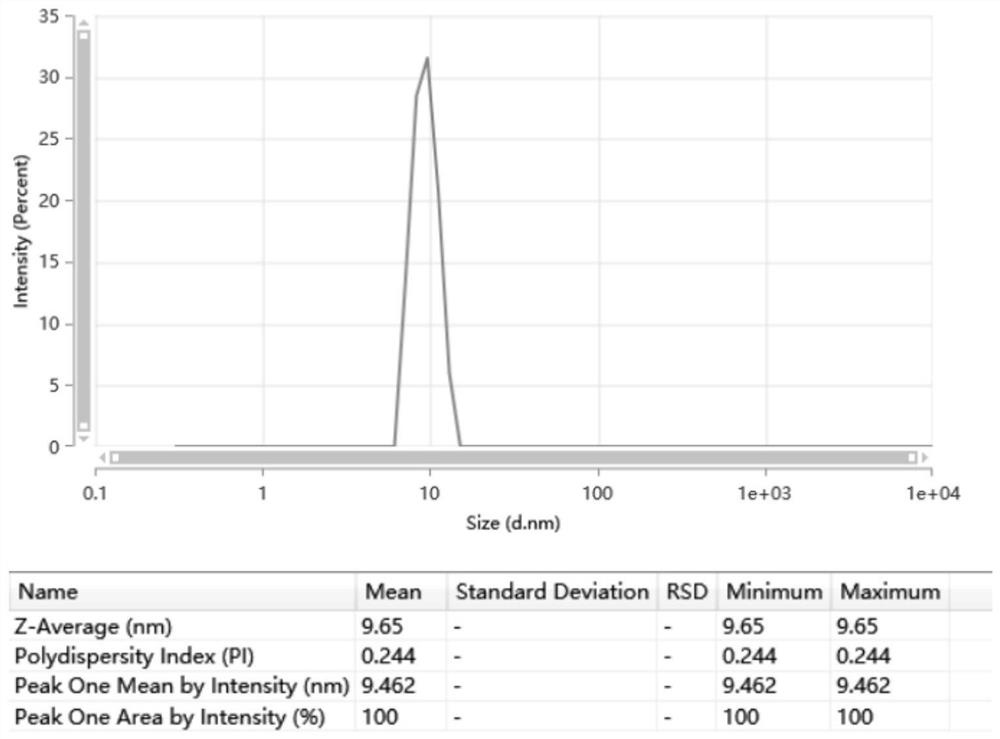

Nano calamine antibacterial silicone rubber, preparation method thereof and application of nano calamine antibacterial silicone rubber in antibacterial medical instruments

PendingCN114045035AImprove securityHas broad-spectrum antibacterial propertiesVulcanizationUrethral catheter

The invention relates to a preparation method of nano calamine antibacterial silicone rubber, which comprises the following steps of: preparing 1-50nm nano calamine with uniform size through wet ball milling, doping the nano calamine into silicone rubber, banburying and blending, vulcanizing, and carrying out hot press molding. Through cooperation of all the raw materials and all the steps, the nano calamine antibacterial silicone rubber which is high in safety, good in antibacterial property and long-acting can be obtained, and the nano calamine antibacterial silicone rubber has broad-spectrum antibacterial property and has high antibacterial rate on gram-negative bacteria and gram-positive bacteria. The invention also relates to an application of the provided nano calamine antibacterial silicone rubber in antibacterial medical instruments, including but not limited to urethral catheters.

Owner:THE GBA NAT INST FOR NANOTECHNOLOGY INNOVATION

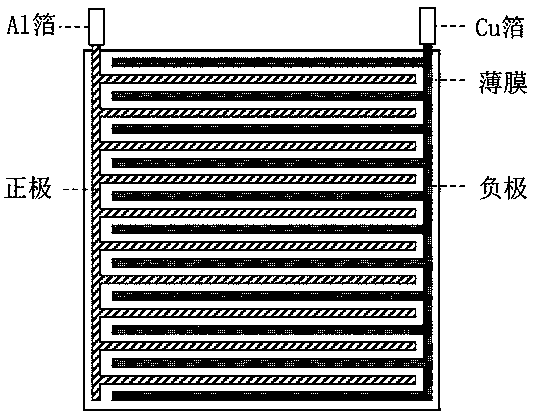

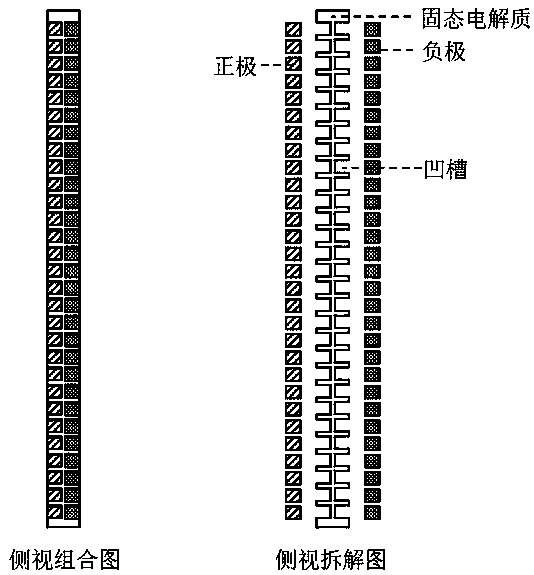

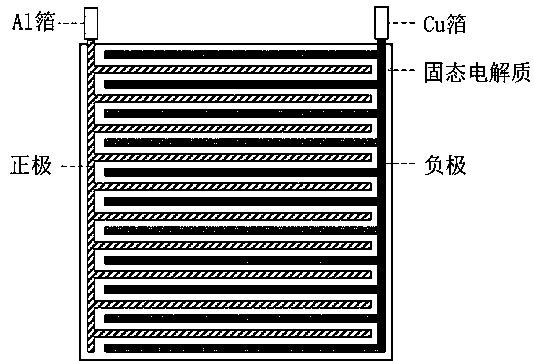

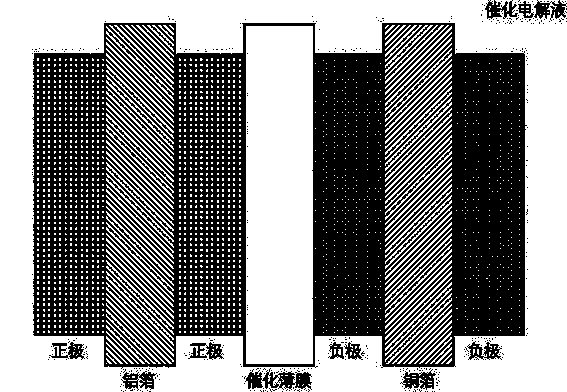

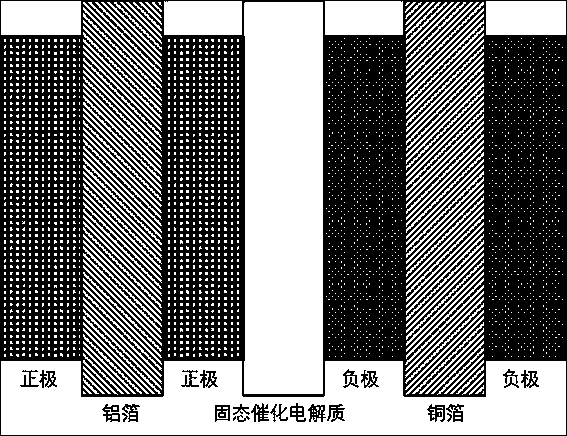

Design method of lithium ion battery structure

InactiveCN109687032AImprove the safety of useWeaken the hidden danger of internal short circuitFinal product manufactureElectrolyte accumulators manufactureSolid state electrolyteEngineering

The invention provides a novel lithium ion battery structure design method. A lithium ion battery structure is designed as that a positive electrode material and a negative electrode material are applied to the same side of a film, or the positive electrode material and the negative electrode material are embedded into a solid electrolyte material. The structure design method has the advantages that migration movement of lithium ions occur laterally in the film or solid electrolyte, thereby weakening the internal short-circuit hidden danger caused by film breakage or solid electrolyte breakdown, and improving the safety of the lithium ion battery in use. The method is novel in design and easy to produce in an industrialized way and has a good application prospect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

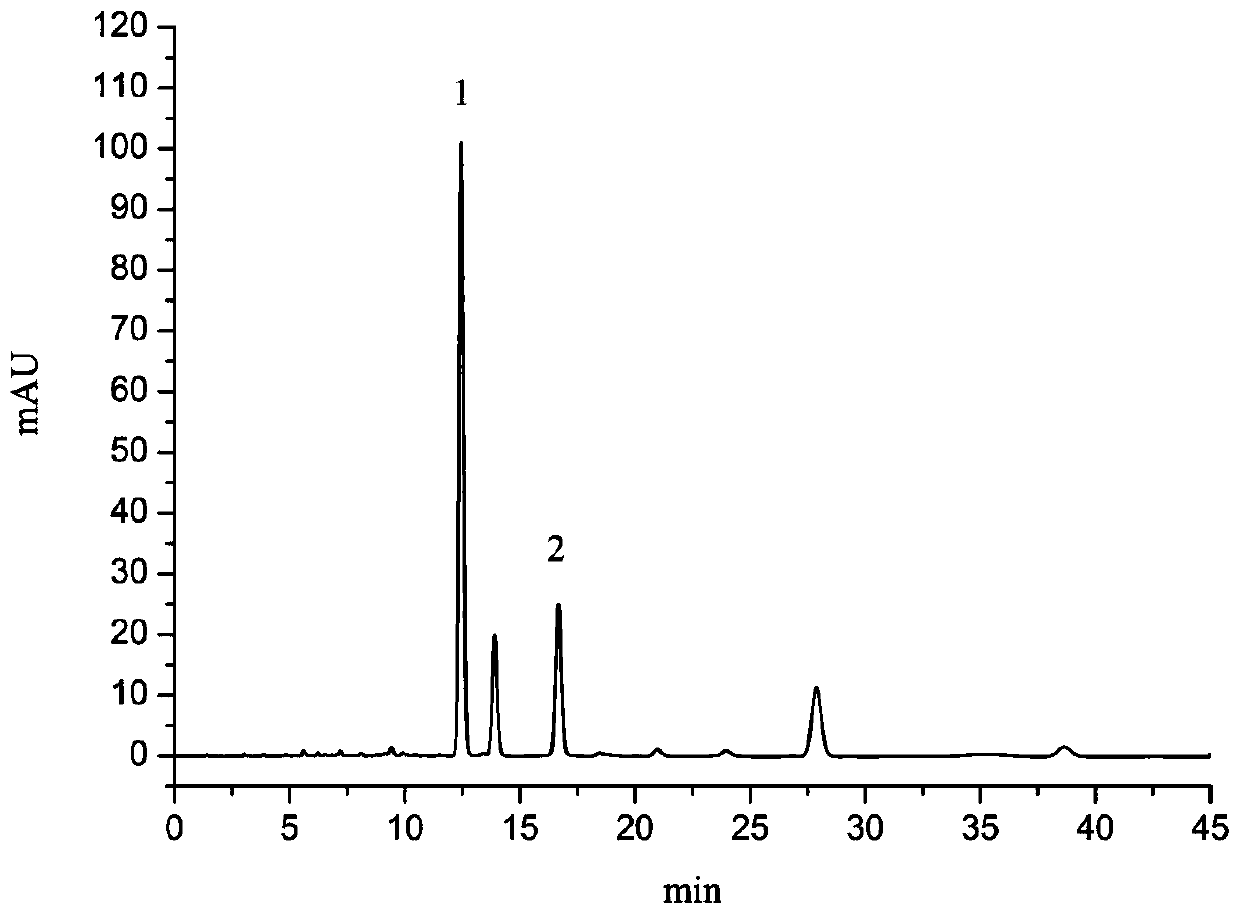

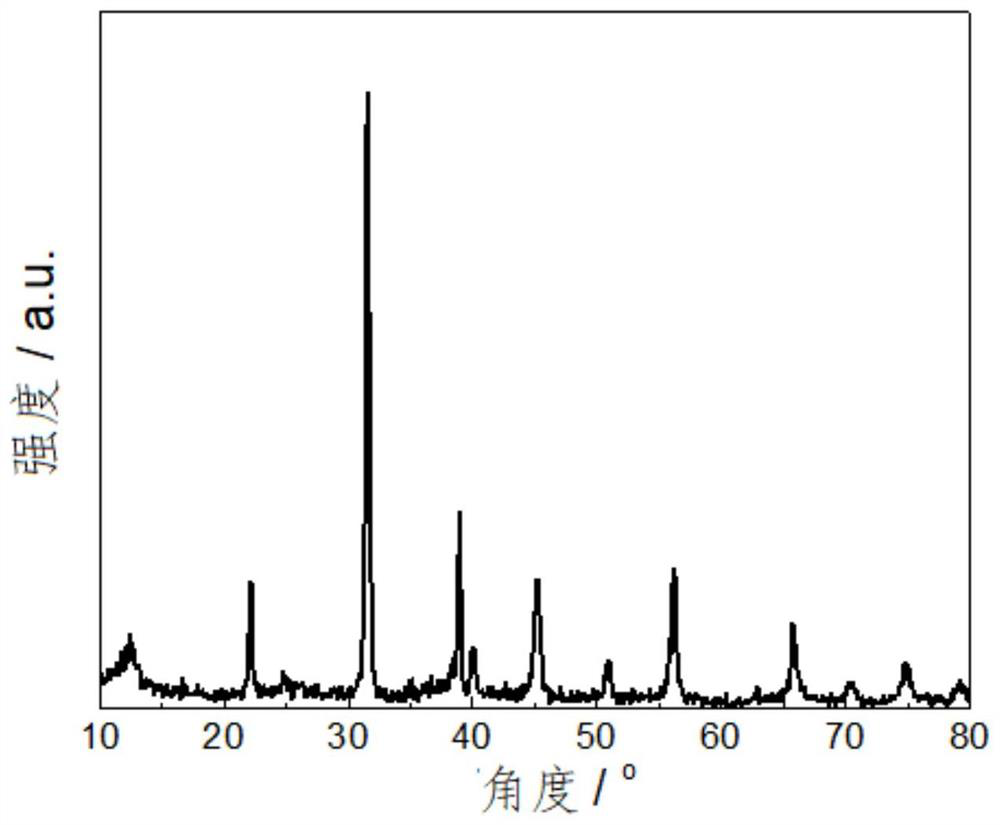

Method for extracting and separating Eupatorium adenophorum ketone compounds from Eupatorium adenophorum

ActiveCN110437053AHigh purityImprove transfer rateOrganic chemistry methodsCarbonyl compound separation/purificationDistillationKetone

The invention discloses a method for extracting and separating Eupatorium adenophorum compounds from Eupatorium adenophorum. The method comprises the following steps: medicinal material air-drying andcrushing, supercritical CO2 extraction, molecular distillation separation, and industrial chromatographic purification for finally obtaining euptox A and 9-oxoageraphorone. The method has the advantages of high purity of the obtained products, high transfer rate, reasonable and feasible whole technology, simple process, simplicity and easy recovery of a solvent, suitableness for large-batch industrial production, and very strong practical values.

Owner:SUN YAT SEN UNIV

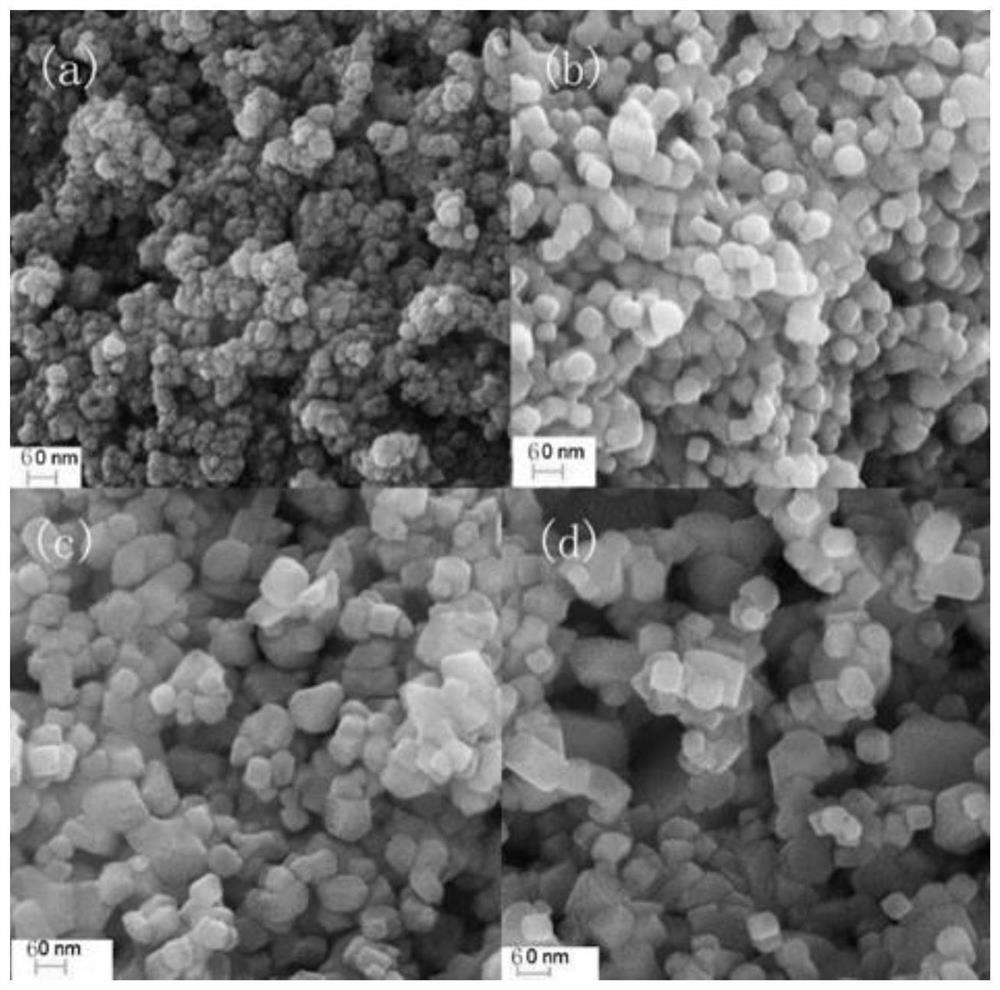

A kind of ultra-high dielectric constant composite material, its preparation method and application

InactiveCN109003821BEasy to operateLow priceAlkaline earth titanatesZinc oxides/hydroxidesDielectricOxide composite

The invention relates to a new type of ultra-high dielectric constant composite material, preparation method and application. It is an oxide composite material formed by n-type semiconducting metal oxide and p-type semiconducting metal oxide with pn junction. Relative permittivity exceeds 10 5 above. The present invention also provides a method for preparing the ultra-high dielectric constant composite material, which involves combining p-type semiconducting metal oxide powder and n-type semiconducting oxide powder through physical or chemical methods to oxidize p-type pn junctions are formed between material particles and n-type oxide particles. These oxide particles with pn junctions are pressed or sintered to form new composite materials with ultra-high dielectric constants.

Owner:NORTHEASTERN UNIV LIAONING

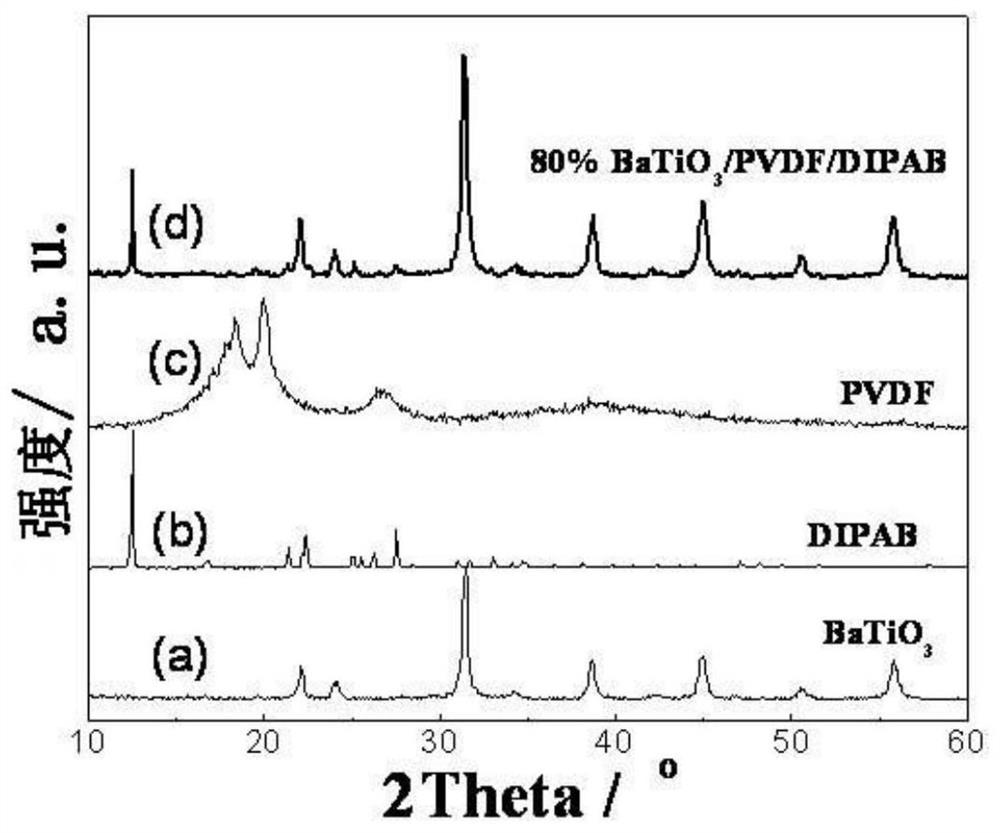

An organic/inorganic ferroelectric composite material with ultra-high dielectric constant, its preparation method and application

InactiveCN110164694BEasy to operateLow priceCapacitor electrolytes/absorbentsPolymer sciencePolymer chemistry

The invention relates to an organic / inorganic ferroelectric composite material with ultra-high dielectric constant, its preparation method and application, which involves filling organic ferroelectric macromolecules and ferroelectric polymers with inorganic powder fillers with ferroelectric properties. In the formed matrix composite, a new type of organic / inorganic ferroelectric composite material is formed. At room temperature, its relative dielectric constant at power frequency is greater than 10 5 . Its preparation method is simple to operate, low in price, and easy to be industrially produced in large quantities. This new ultra-high dielectric material can be used to prepare new high-capacity all-solid-state capacitor materials suitable for surface mounting. It has a variety of interface charge polarizations, breaking through the current pre-percolation theory of dielectric theory and providing new ways for material applications and further research.

Owner:NORTHEASTERN UNIV LIAONING

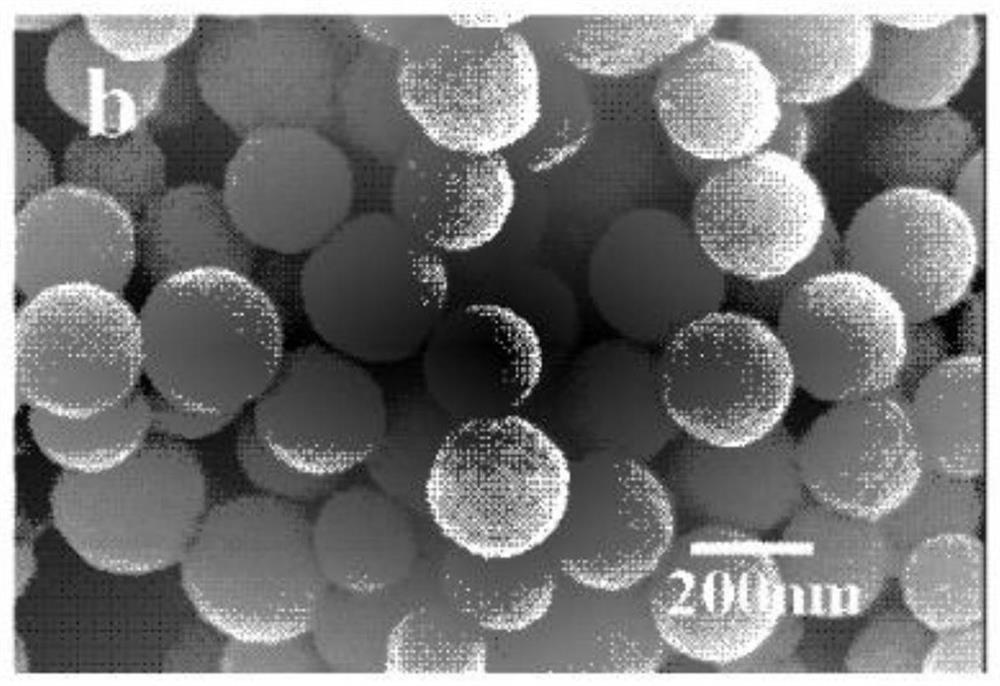

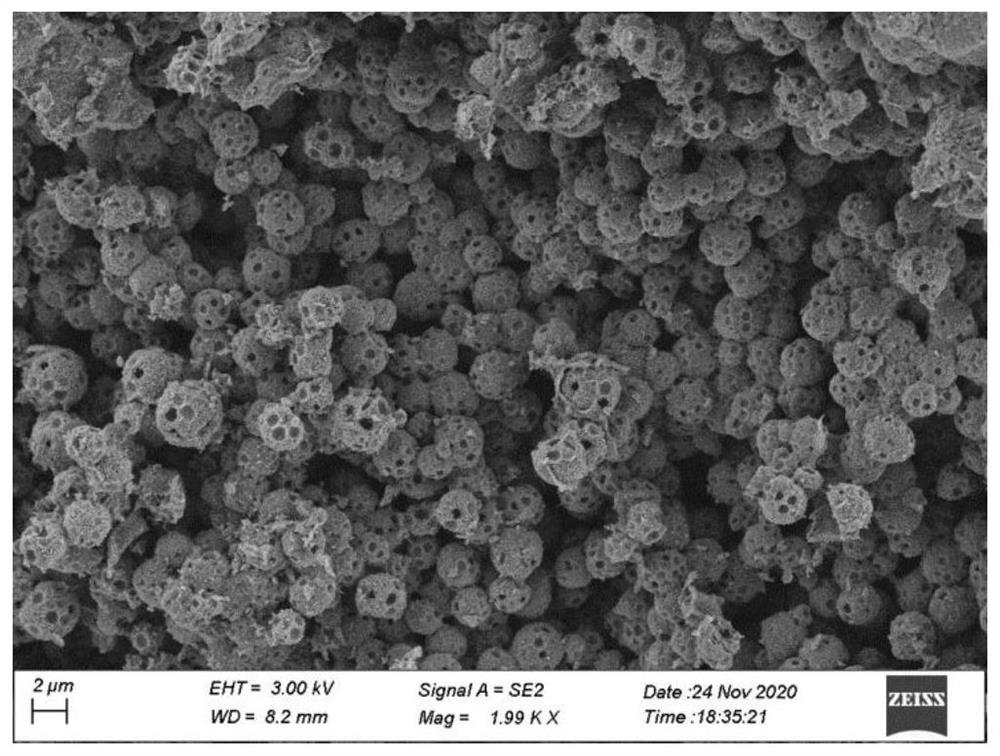

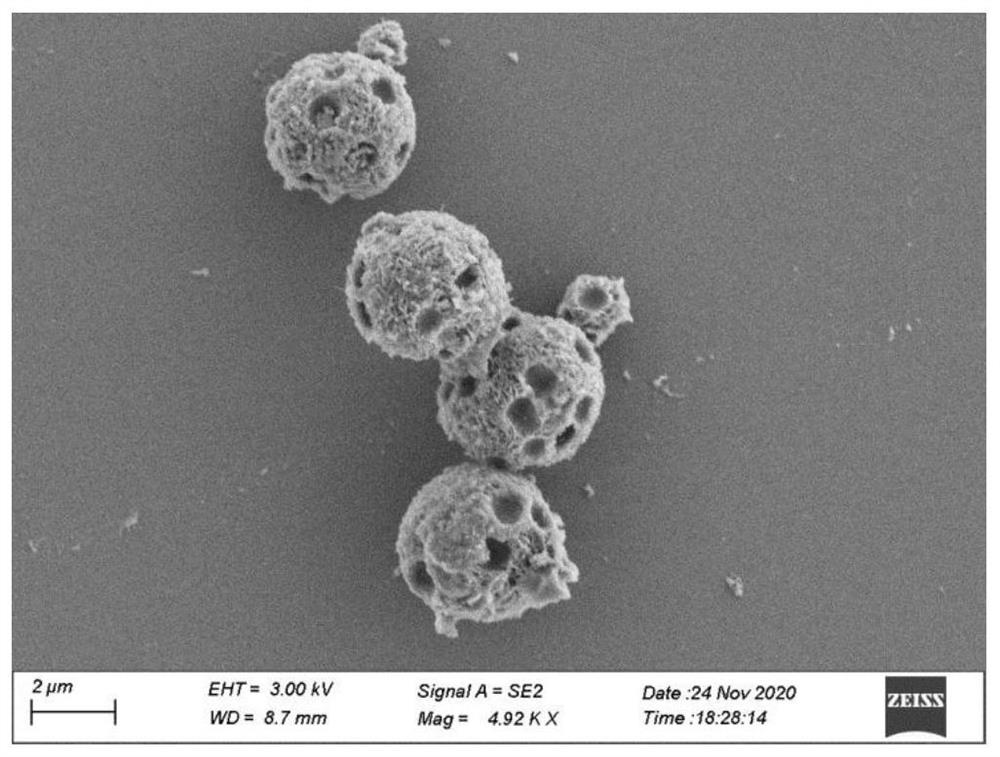

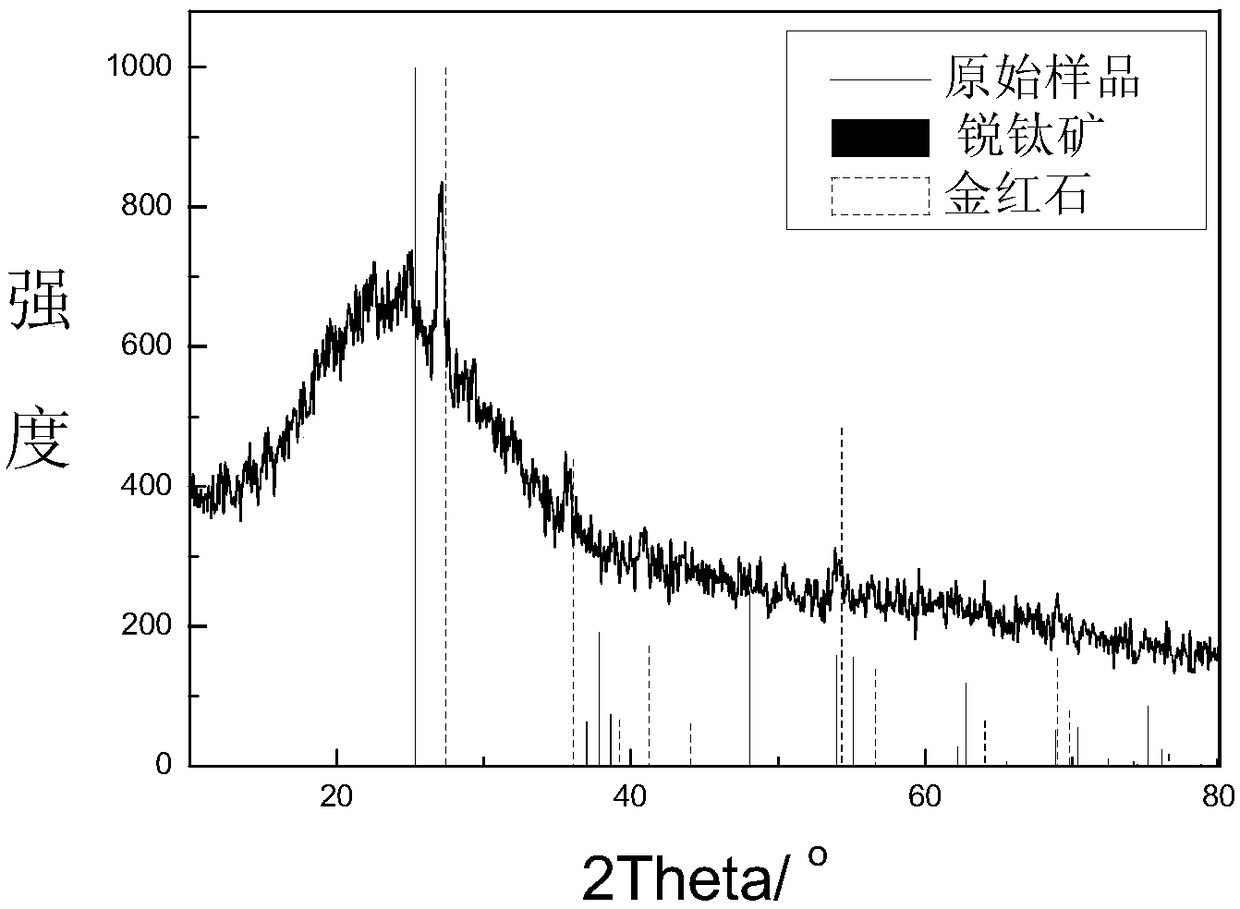

Preparation method of titanium dioxide porous spheres

PendingCN114162860AAdvantages of preparation methodIncreased active surfaceTitanium dioxideSodium phosphatesWater chlorination

The invention provides a preparation method of titanium dioxide porous spheres, which comprises the following steps: (1) sequentially adding ultrapure water, hydroquinone and sodium hexametaphosphate into a reagent bottle for shading preservation, and stirring for 30-150 minutes to obtain a solution 1; (2) adding titanium trichloride into a hydrochloric acid solution with the concentration of 30%, and stirring for 10-60 minutes to obtain a solution 2; (3) dropwise adding the solution 2 into the solution 1, and stirring for 24-72 hours to obtain a solution 3; (4) transferring the solution 3 into a hydrothermal kettle, and treating for 12-24 hours; and (5) centrifugally separating the product, washing for three times, and finally drying for 12 hours to obtain the target product. Through the synergistic effect of specific organic matter hydroquinone and sodium hexametaphosphate, in the process of regulating and controlling titanium trichloride to generate titanium dioxide particles in a hydrothermal mode, micron-sized titanium dioxide porous balls with the surfaces rich in nanopores are generated, the active surface of a catalytic reaction is widened, the catalytic activity is improved, the product preparation process is simple, and the preparation method is suitable for industrial production. And large-scale industrial production is facilitated.

Owner:耐酷时(北京)科技有限公司

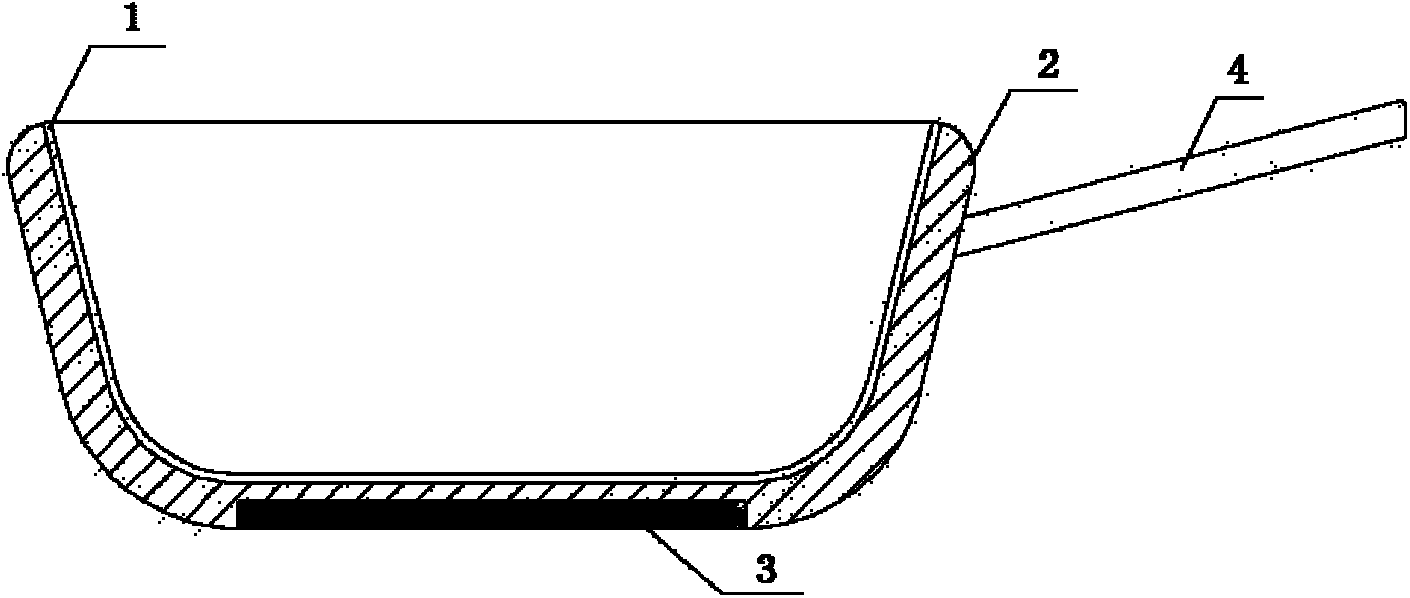

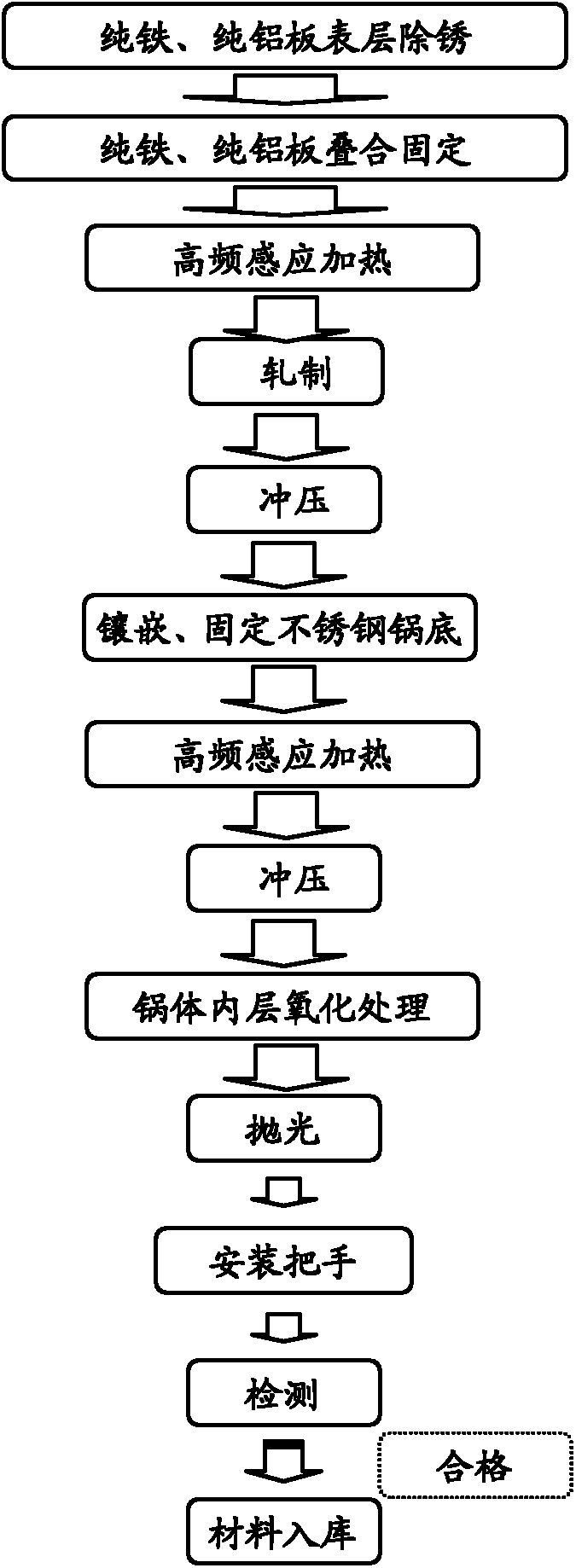

Pot for iron-aluminum combined induction cooker and manufacture method thereof

InactiveCN102389266BHigh bonding strengthIncrease productivityCooking-vessel materialsSurface oxidationEnergy conservation

The invention discloses a pot for an iron-aluminum combined induction cooker and a manufacture method thereof. The manufactured entire pot body is composed of a two-layer material, wherein the inner layer is a thin pure-iron material which is subjected to surface oxidation treatment, and the outer layer is composed of pure aluminum or an aluminum alloy. A stainless steel heating element for the induction cooker is embedded in the bottom of the pot. The preparation method comprises the following steps: performing hot rolling to combine a pure iron plate and a pure aluminum plate, then rolling, and stamping to embed a stainless steel plate in the outer bottom of the pot body. The prepared pot is as light as the aluminum pot, the dish cooked by using the pot has the same taste of that cooked by using the iron pot and is as healthy and environmentally-friendly as the iron pot, the pot is suitable to be heated by various heat sources and can be used on the induction cooker or other stoves; and the pot has the advantages of high production efficiency, energy conservation, low production cost, easy large-scale industrial production and the like. A set of equipment can be used to produce the existing combined pot bodies with different specifications and the dimension can be completely adjusted according to the needs of customers.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

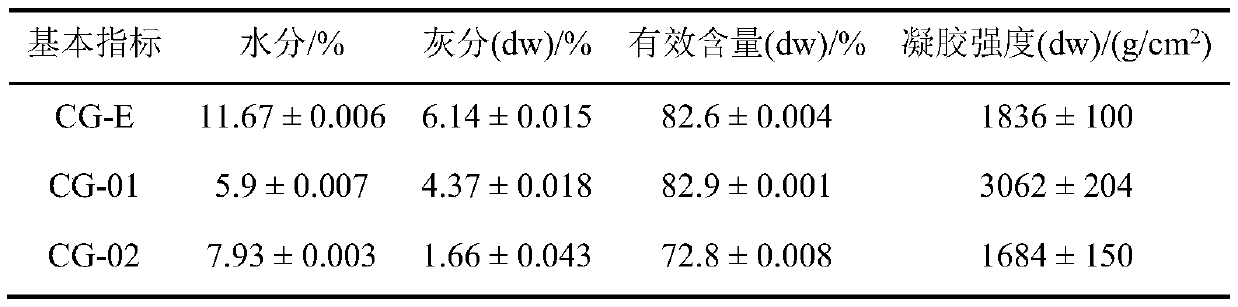

Method for preparing dry rice flour by using curdlan

PendingCN111296740ARaw materials are easy to getSimple and fast operationFood ingredient as gelling agentProcess engineeringFood processing

The invention discloses a method for preparing dry rice flour by using curdlan, and belongs to the technical field of food processing. The preparation method comprises the following steps: cleaning indica rice, performing drying, performing pulverizing, and performing sieving; adding curdlan into the indica rice powder, and performing uniform mixing; putting the obtained mixture into a double-screw extruder, and performing gelatinizing and extruding formation to obtain rice flour; and finishing the rice flour, and performing aging and drying to obtain the dry rice flour product. The method issimple and feasible and is low in cost, and the prepared dry rice flour has better cooking characteristics and higher strength, elasticity, chewiness and aging performance, so that the defects of highbrittleness, easy breaking and insufficient toughness of existing dry rice flour are well overcome. Therefore, the method provided by the invention has a wide market prospect.

Owner:JIANGNAN UNIV

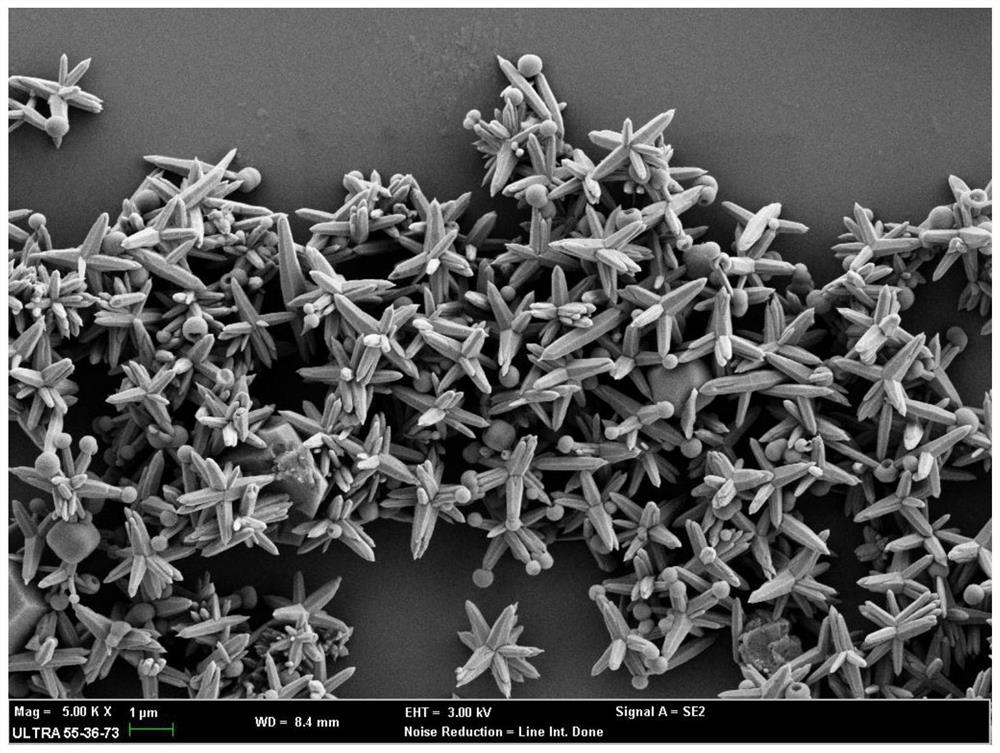

Titanium dioxide/zinc oxide heterojunction material with dendritic structure and preparation method thereof

ActiveCN113083276AEasy to separateHigh catalytic efficiencyMetal/metal-oxides/metal-hydroxide catalystsHexamethylenetetraminePolyethylene-polypropylene glycol

The invention discloses a titanium dioxide / zinc oxide heterojunction material with a dendritic structure and a preparation method thereof. The preparation method comprises the following steps: 1) mixing 1-7 parts by weight of p-methyl phenylethylamine, 1-7.4 parts by weight of polyethylene-polypropylene glycol and 10-40ml of water to obtain a solution 1; 2) adding 1 to 5 parts (by weight) of zinc nitrate (Zn(NO3)<2>.6 H2O) and 0.5 to 7 parts (by weight) of hexamethylenetetramine ((CH2)6N4) into 5 to 15 ml of ethylenediamine (C2H8N2) solution, so as to obtain a solution 2; 3) adding the solution 2 into the solution 1, and adding 0.2-0.7 part (weight ratio) of n-butyl titanate while stirring; (4) carrying out hydrothermal treatment on the solution obtained in the step (3) to obtain a solution containing the dendritic heterojunction material. The unique titanium dioxide / zinc oxide heterojunction material with the dendritic structure is obtained, the preparation process is relatively simple and easy to control, and large-scale industrial production is facilitated.

Owner:ZHEJIANG SCI-TECH UNIV

A kind of titanium dioxide and preparation method thereof

ActiveCN113087013BLarge specific surface areaMaintain catalytic activityTitanium dioxideZinc nitrateTitanium tetrachloride

Owner:ZHEJIANG SCI-TECH UNIV

Lithium-ion battery structure design method

InactiveCN110459811AImprove the safety of useSolve the problem of internal short circuitFinal product manufactureSecondary cells manufactureSolid state electrolyteElectrical battery

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Pyrolysis synthesis method of TiO2 nano-particles under control of electric field

InactiveCN109319836AAchieve controlled growthAvoid growing upMaterial nanotechnologyTitanium dioxideSynthesis methodsDissolution

The invention discloses a novel synthetic method of TiO2 nano-particles and belongs to the technical field of preparation of oxides with nanostructures. The method comprises the following steps of adding titanium salt in a proper solvent, performing dissolution to obtain an injection, adding the injection in an injector, performing pouring with an injection pump, enabling droplets out of a needleto form a nanometer beam flow under the effect of a certain external electric field, and performing pyrolysis on the nanometer beam flow to produce required TiO2 nano-particles. The synthetic method does not need to perform reaction with solution or high-temperature calcination and can be very convenient to prepare the TiO2 nano-particles with the diameter being 10-100 nm. Without high-temperaturecalcination, the method avoids growth and aggregation of crystal grains and keeps high activity of the crystal grains. Compared with the hydrothermal synthesis method, the method does not need high-temperature and high-pressure super-critical state, simplifies the technology, is simple to operate and low in cost, greatly lowers the equipment requirement and is easy in mass industrial production.

Owner:东北大学秦皇岛分校

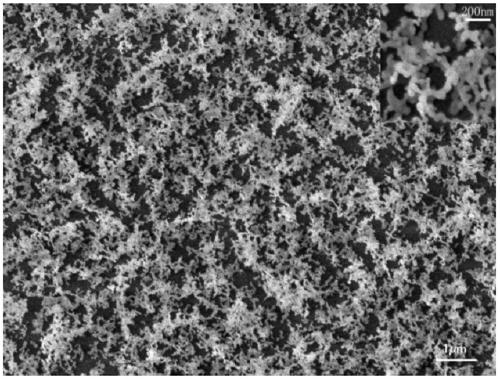

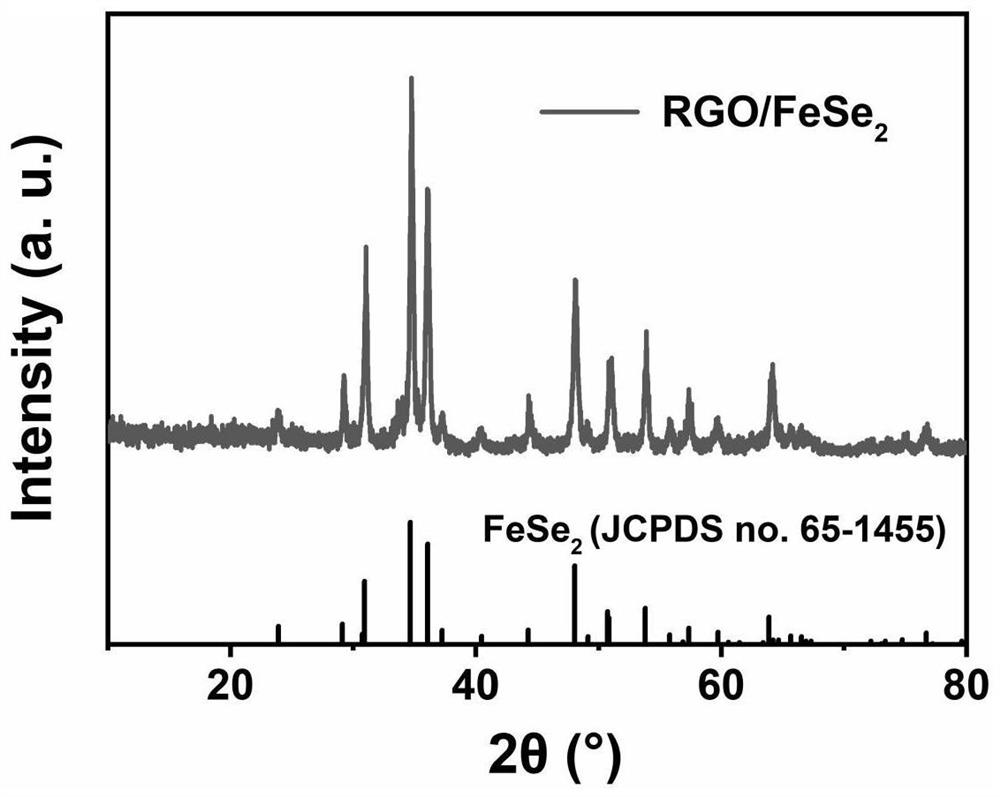

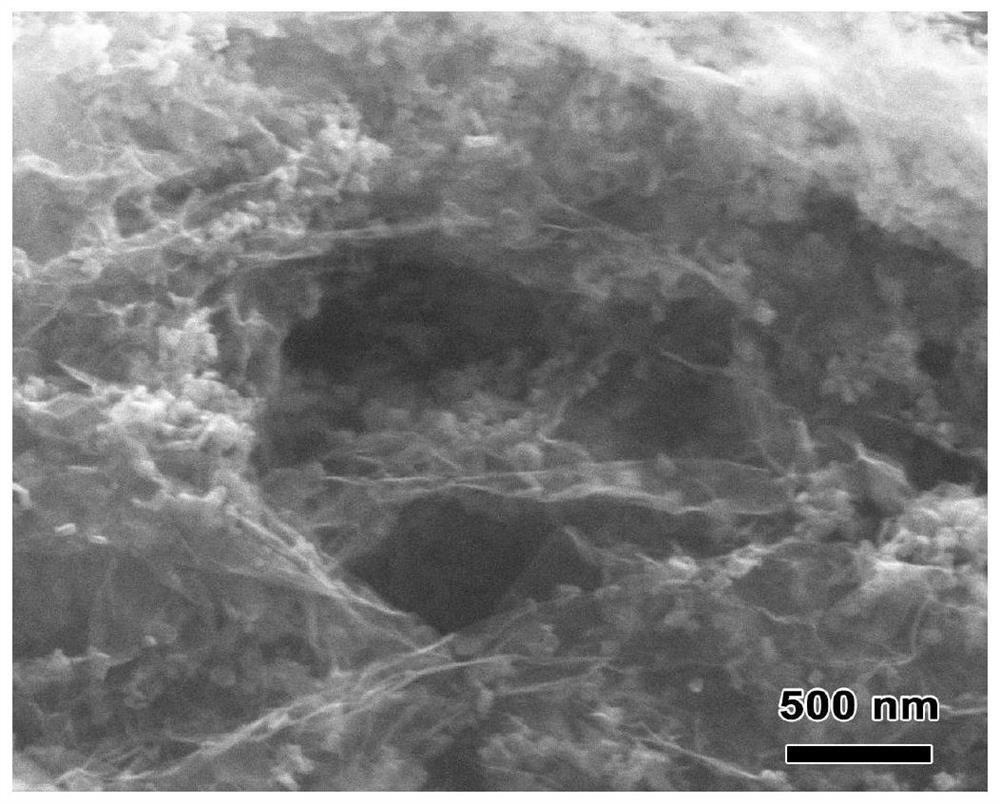

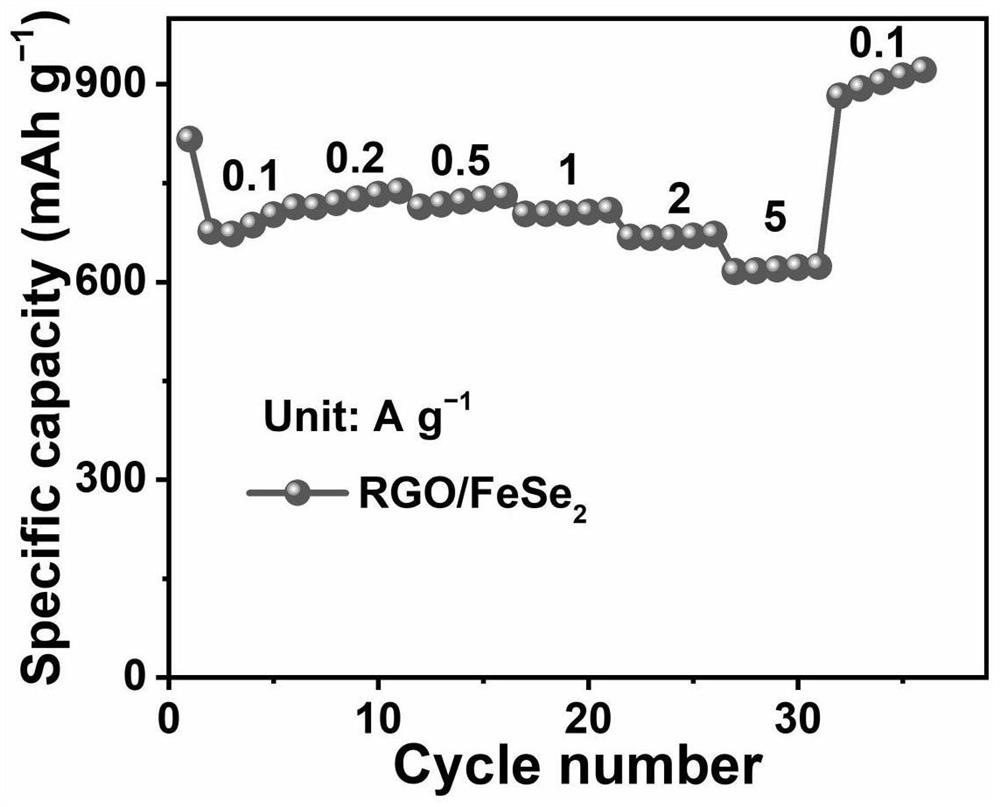

Graphene/iron diselenide composite material for lithium ion battery negative electrode material, and preparation method thereof

ActiveCN113745475AAvoid problemsAvoid volumeMaterial nanotechnologySecondary cellsNanoparticleGraphite

The invention discloses a graphene / iron diselenide composite material for a lithium ion battery negative electrode material, and a preparation method thereof, and belongs to the field of lithium ion battery negative electrode materials and preparation thereof. The invention aims to solve the technical problem that the capacity is rapidly attenuated and even the battery is invalid due to the violent volume change of the existing iron diselenide negative electrode material in the lithium intercalation process. The graphene / iron diselenide composite material disclosed by the invention is composed of a wrinkled graphene nanosheet, iron diselenide nanoparticles uniformly distributed on the wrinkled graphene nanosheet, and iron diselenide nanoparticles wrapped by the wrinkled graphene nanosheet. When the prepared composite material is used as a lithium ion battery negative electrode material, the volume expansion of iron diselenide during lithium intercalation can be effectively reduced, the specific capacity and the rate capability of the electrode material are remarkably improved, the defects of a single iron diselenide material are well overcome, and the preparation method is short in technological process, simple and controllable to operate, low in cost and easy in large-scale industrial production.

Owner:HARBIN ENG UNIV

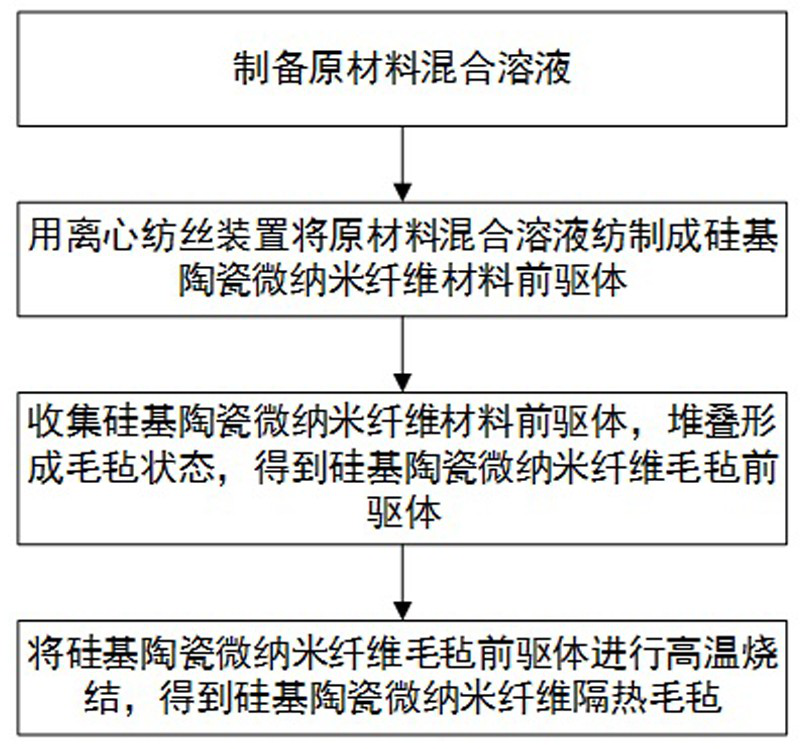

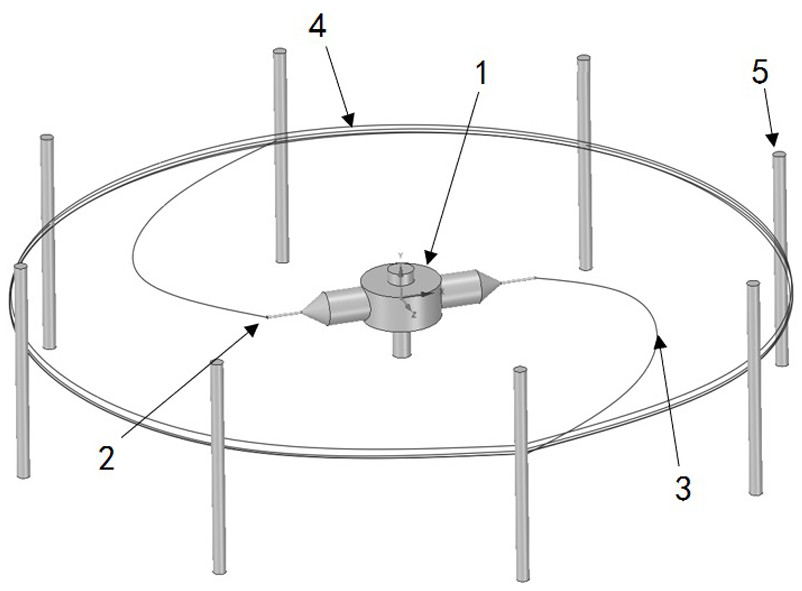

A kind of silicon-based ceramic micro-nano fiber thermal insulation felt and preparation method thereof

Owner:佛山市中柔材料科技有限公司

Manufacturing technology of electrolyte used for emergency power supply equipment

InactiveCN107221703AFast dryingReduce generationOrganic electrolyte cellsSecondary cellsManufacturing technologyWater of crystallization

The invention provides a manufacturing technology of an electrolyte used for emergency power supply equipment. The manufacturing technology comprises the following steps: a, putting a lithium iodide salt with crystal water in a vacuum environment for drying; b, adding the dried lithium iodide salt into an organic solvent for uniform stirring to obtain an electrolyte mother solution; c, adding the electrolyte mother solution into an electrolytic tank, and adopting a constant current for electrolysis for 5 to 8 h to obtain a crude electrolyte I; d, adding a stabilizer into the crude electrolyte I, and reacting for 8 to 10 h at the temperature of 40 to 60 DEG C to obtain a crude electrolyte II; and e, adding a water removing agent into the crude electrolyte II, stirring for 1 to 2 h, and filtering to obtain the electrolyte finished product. The manufacturing flow of the electrolyte is simple, the reaction condition is easy to control, the production cost is low, the electrolyte is stable in concentration performance and stable in viscosity, the internal instance of a battery can be effectively reduced, the using temperature range is wide, and the electrolyte is easy for large-scale industrial production.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Preparation method of cylindrical titanium dioxide hollow particles

ActiveCN114162859AIncrease active areaHigh catalytic activityPhysical/chemical process catalystsWater/sewage treatment by irradiationPropanoic acidPolyethylene-polypropylene glycol

The invention provides a preparation method of cylindrical titanium dioxide hollow particles, which comprises the following steps: (1) mixing and stirring 3-(4-toluene) propionic acid, p-methyl phenylethylamine, polyethylene-polypropylene glycol and 10-20ml of ultrapure water for 3-5 hours to form a transparent solution; (2) adding organic titanate into the transparent solution obtained in the step (1), and stirring for 3-10 minutes; (3) putting the solution in the step (2) into a high-pressure kettle, and reacting for 24-48 hours; (4) after centrifugal separation, washing a white product; (5) transferring a product obtained in the step (4) into an HCl / ethanol mixed solution, and stirring; and (6) after centrifugal separation, washing the precipitate to obtain a target product. Under a hydrothermal condition, tetrabutyl titanate is hydrolyzed into crystals through a specific ternary induction system, and unique cylindrical titanium dioxide hollow particles are obtained. The active area of catalytic reaction is greatly expanded, and the catalytic activity is improved. The preparation process of the product is relatively simple, conditions are easy to control, and large-scale industrial production is easy.

Owner:耐酷时(北京)科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Calix[4]arene adenine derivative-oxidized graphene compound, preparation method and applications thereof Calix[4]arene adenine derivative-oxidized graphene compound, preparation method and applications thereof](https://images-eureka.patsnap.com/patent_img/80827070-760f-47a7-bf49-b957909f97d2/HDA0000943785520000011.PNG)

![Calix[4]arene adenine derivative-oxidized graphene compound, preparation method and applications thereof Calix[4]arene adenine derivative-oxidized graphene compound, preparation method and applications thereof](https://images-eureka.patsnap.com/patent_img/80827070-760f-47a7-bf49-b957909f97d2/HDA0000943785520000012.PNG)

![Calix[4]arene adenine derivative-oxidized graphene compound, preparation method and applications thereof Calix[4]arene adenine derivative-oxidized graphene compound, preparation method and applications thereof](https://images-eureka.patsnap.com/patent_img/80827070-760f-47a7-bf49-b957909f97d2/HDA0000943785520000021.PNG)