A kind of titanium dioxide and preparation method thereof

A technology of titanium dioxide and weight ratio, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of decreased catalytic activity, loss of large specific surface area, and agglomeration of nanomaterials, and achieves a simple and large-scale preparation process. The specific surface area and the effect that the conditions are easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

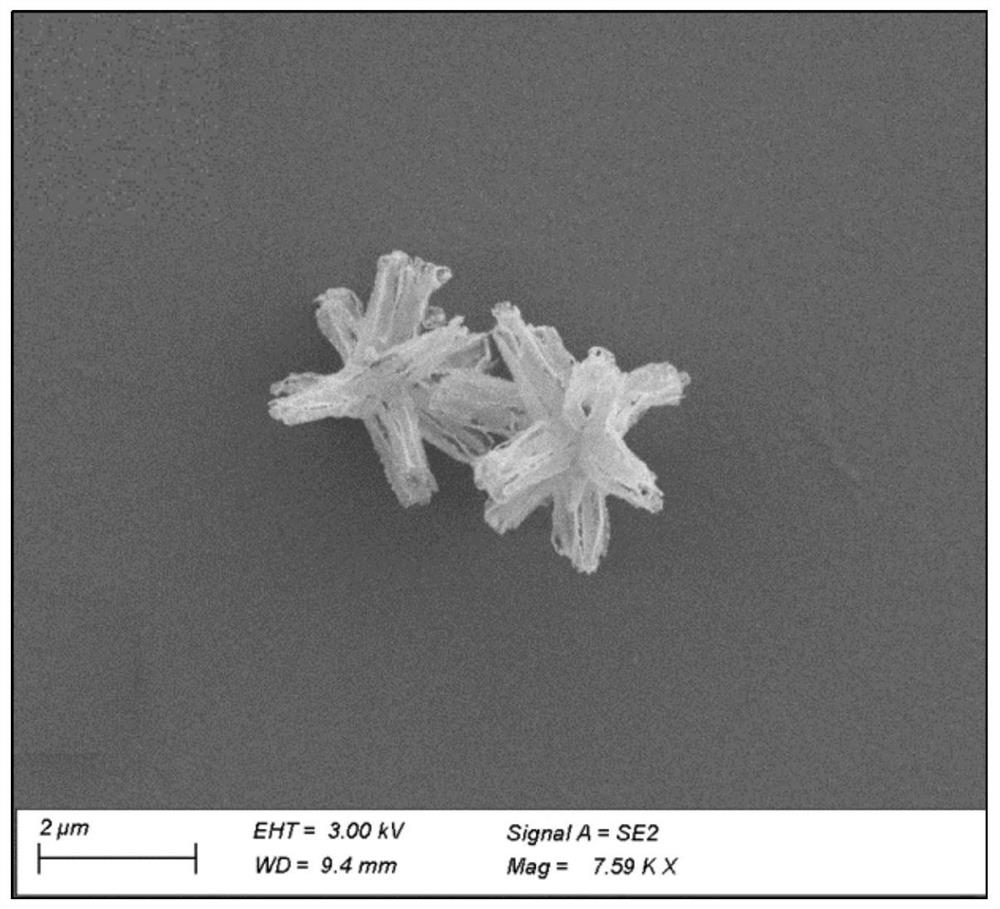

Image

Examples

Embodiment 1

[0034] A preparation method of titanium dioxide material, comprising the steps:

[0035] 1) dissolve 0.1 part (weight ratio) of zinc nitrate in 30 parts (weight ratio) of methanol, stir for 5 minutes to obtain solution 1;

[0036] 2) Dissolve 0.1 part (weight ratio) of 2-methylimidazole in 30 parts (weight ratio) of methanol, stir for 5 minutes to obtain solution 2;

[0037] 3) Mix and stir solution 1 and solution 2 for 1 minute, and leave standstill to react for 18 hours at a temperature of 3 degrees to obtain solution 3;

[0038] 4) adding 0.1 part (weight ratio) of titanium tetrachloride to solution 3, after stirring for 2 hours, adding 0.1 part (weight ratio) methanol solution to obtain solution 4, the methanol solution comprising 5 parts (weight ratio) water and 90 parts (weight ratio) methanol;

[0039] 5) After the solution 4 was stirred for 12 hours, centrifuged; the white product was washed three times with ethanol and deionized water to obtain a titanium dioxide ma...

Embodiment 2

[0043] A preparation method of titanium dioxide material, comprising the steps:

[0044] 1) dissolve 1 part (weight ratio) of zinc nitrate in 50 parts (weight ratio) of methanol, and stir for 15 minutes to obtain solution 1;

[0045] 2) 2 parts (weight ratio) of 2-methylimidazole are dissolved in 50 parts (weight ratio) of methanol, stirred for 15 minutes to obtain solution 2;

[0046] 3) Mix and stir solution 1 and solution 2 for 5 minutes, and leave standstill to react for 24 hours at a temperature of 5 degrees to obtain solution 3;

[0047] 4) adding 2 parts (weight ratio) of titanium tetrachloride to solution 3, after stirring for 4 hours, adding 5 parts (weight ratio) methanol solution to obtain solution 4, the methanol solution comprising 10 parts (weight ratio) water and 95 parts (weight ratio) methanol;

[0048] 5) After the solution 4 was stirred for 36 hours, centrifuged; the white product was washed three times with ethanol and deionized water to obtain a titanium...

Embodiment 3

[0050] A preparation method of titanium dioxide material, comprising the steps:

[0051] 1) dissolve 0.5 part (weight ratio) of zinc nitrate in 40 parts (weight ratio) of methanol, stir for 10 minutes to obtain solution 1;

[0052] 2) 1 part (weight ratio) of 2-methylimidazole was dissolved in 40 parts (weight ratio) of methanol, and stirred for 10 minutes to obtain solution 2;

[0053] 3) Mix and stir solution 1 and solution 2 for 3 minutes, and leave standstill to react for 21 hours at a temperature of 4 degrees to obtain solution 3;

[0054] 4) adding 1 part (weight ratio) of titanium tetrachloride to solution 3, after stirring for 3 hours, adding 3 parts (weight ratio) methanol solution to obtain solution 4, the methanol solution comprising 7 parts (weight ratio) water and 93 parts (weight ratio) methanol;

[0055] 5) After the solution 4 was stirred for 24 hours, centrifuged; the white product was washed three times with ethanol and deionized water to obtain a titanium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com