Composite material having pn junction structure for supercapacitor, supercapacitor electrode material and preparation method thereof

A technology of supercapacitors and composite materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of internal resistance drop, working voltage drop, unfavorable supercapacitor energy storage density, etc., and increase the energy storage density , increase the resistance, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] MnO in this example 2 The synthesis of according to the chemical reaction equation:

[0048] MnSO 4 +H 2 o 2 +2NaOH=MnO 2 +2H 2 O+Na 2 SO 4

[0049] To be done.

[0050] First 4.66gBaTiO 3 powder in H 2 Heat treatment at 900°C for 8 hours in air.

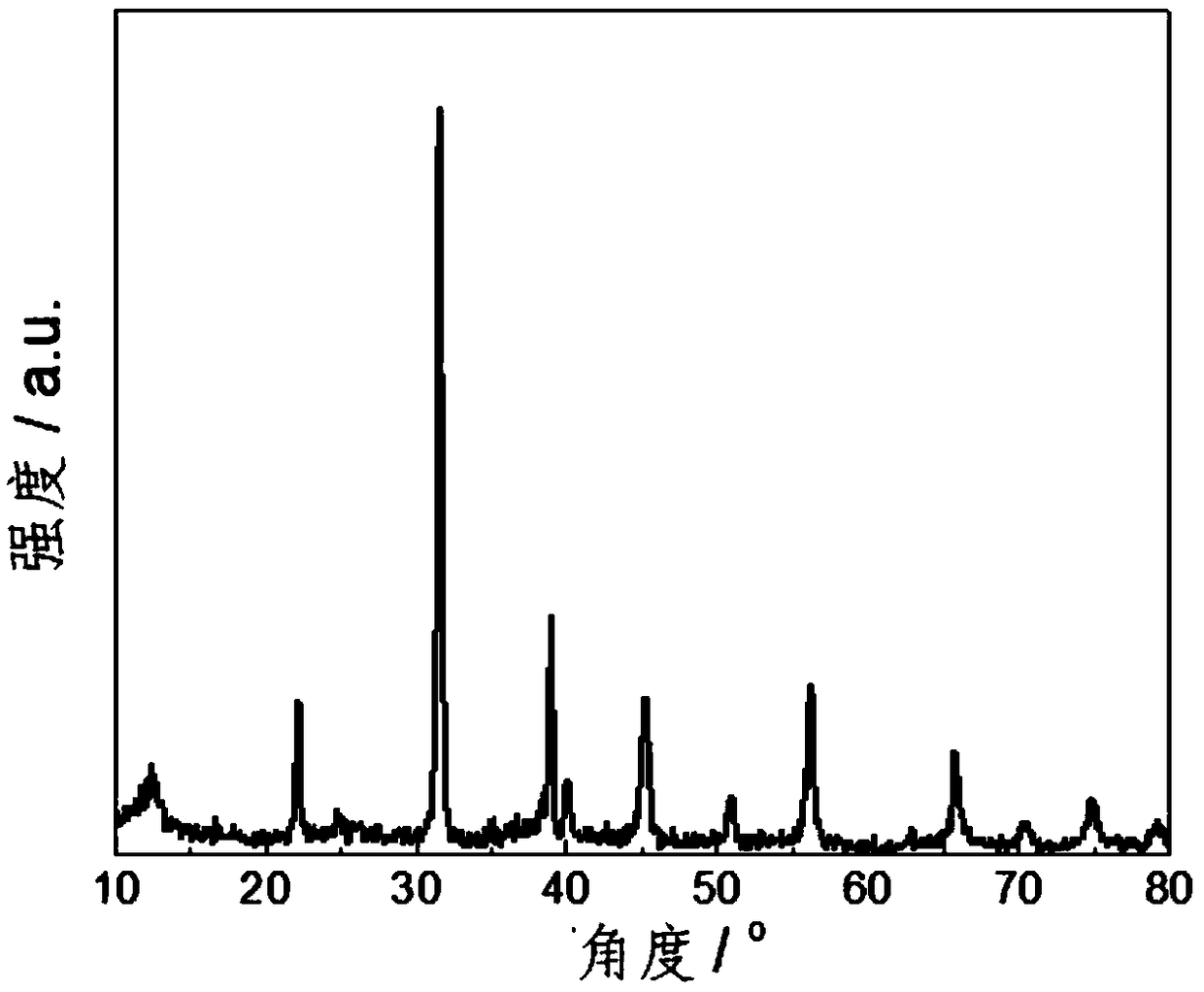

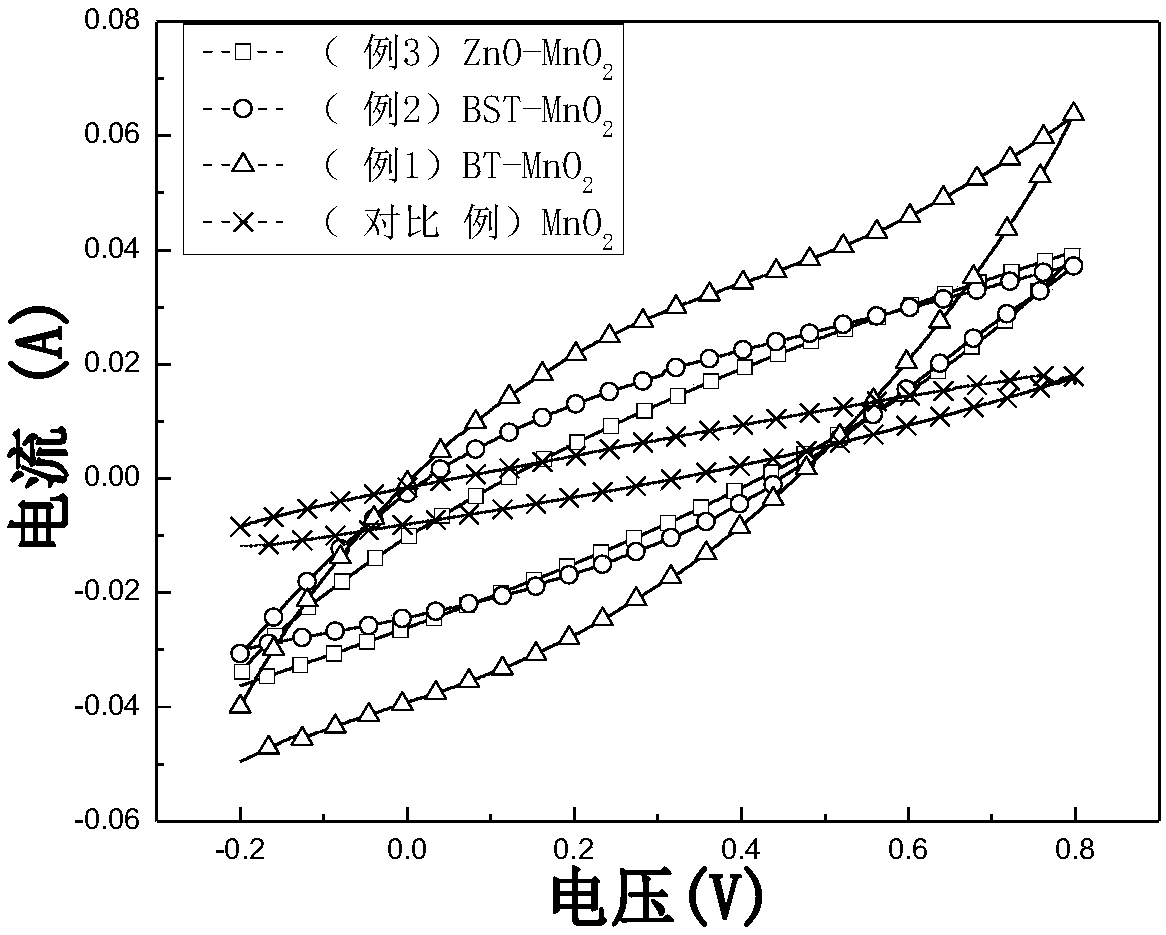

[0051] Composite materials with pn junctions were obtained by in situ synthesis. Weigh 1.6g NaOH into a beaker, add 200ml deionized water to dissolve, and put the semiconducted BaTiO 3 The powder was transferred to the prepared NaOH solution, stirred vigorously and heated to 60°C as the base liquid. Weigh 3.38gMn(SO 4 )·H 2 O, put it into a small beaker, add 50mlH 2 O and 5ml 30% HO 2 o 2 Let it dissolve to form a titration solution. Add the titrant solution dropwise to the base solution, keep at 60°C and stir vigorously. After the titration is completed, a dark brown precipitate is obtained. After filtering and drying, the obtained composite powder is subjected to X-ray diffraction (XRD), and the diffracti...

Embodiment 2

[0054] MnO in this example 2 The synthesis of according to the chemical reaction equation:

[0055] MnSO 4 +H 2 o 2 +2NaOH=MnO 2 +2H 2 O+Na 2 SO 4

[0056] To be done.

[0057] The specific operation is as follows:

[0058] (1) First put 0.0226gY 2 o 3 (yttrium oxide) and 4.46g Ba 0.9 Sr 0.1 TiO 3 (BST) The powder was uniformly mixed and ground with an agate mortar for 1 h, then compacted at 1 Mpa, and sintered in air at 1280 ° C for 1 h to make it semiconducting. The cooled porcelain body is pulverized and passed through a 300-mesh sieve. The powder is light blue.

[0059] (2) The composite material with pn junction was obtained by in situ synthesis. Weigh 1.6g NaOH into a beaker, add 200ml deionized water to dissolve; transfer the BST powder that has been semiconducted in step (1) into the prepared NaOH solution, stir vigorously and heat to 80°C as the base liquid. Weigh 3.38gMnSO 4 ·H 2 O, put it into a small beaker, add 50mlH 2 O and 5ml 30% H 2 o 2...

Embodiment 3

[0062] Composite materials with ultrahigh dielectric constant were prepared by chemical liquid phase precipitation, in which MnO 2 The synthesis of according to the chemical reaction equation:

[0063] MnSO 4 +H 2 o 2 +2NaOH=MnO 2 +2H 2 O+Na 2 SO 4

[0064] To be done.

[0065] The specific operation is as follows:

[0066] (1) First, heat-treat 1.628g of ZnO in hydrogen at 800°C for 1h to make it semiconducting.

[0067] (2) The composite material with pn junction was obtained by in situ synthesis. Weigh 1.6g NaOH into a beaker, add 500ml deionized water to dissolve; transfer the ZnO powder that has been semiconducted in step (1) into the prepared NaOH solution, stir vigorously and heat to 60°C as the base liquid. Weigh 3.38gMnSO 4 ·H 2 O, put it into a small beaker, add 50mlH 2 O and 5ml 30% H 2 o 2 Let it dissolve to form a titration solution. Add the titrant solution dropwise to the base solution, keep at 60°C and stir vigorously. After the titration is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com