Nano calamine antibacterial silicone rubber, preparation method thereof and application of nano calamine antibacterial silicone rubber in antibacterial medical instruments

A technology of calamine and silicone rubber, which is applied in the field of antibacterial materials, can solve problems such as clinical application uncertainty, and achieve long-term antibacterial properties, good antibacterial properties, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] In some embodiments of the present invention, the preparation method of described nano calamine antibacterial silicone rubber comprises the steps:

[0072] S100 (wet ball milling): mixing calamine powder, balls and water, performing wet ball milling, drying, and sieving to obtain nano calamine with a particle size of nanometer;

[0073] S200 (banburying and blending): banburying and blending silicone rubber with the nano-calamine to obtain a nano-calamine / silicone rubber blend;

[0074] S300 (vulcanization): adding a vulcanizing agent to the nano-calamine / silicone rubber blend for vulcanization to prepare the nano-calamine antibacterial silicone rubber.

[0075] In some preferred embodiments of the present invention, the preparation method of described nano calamine antibacterial silicone rubber comprises the following steps:

[0076] mixing calamine powder, balls and water, performing wet ball milling, and drying to obtain nano calamine with an average particle size o...

specific Embodiment

[0126] Embodiments of the present invention will be described in detail below in conjunction with examples. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. For the experimental methods that do not indicate specific conditions in the following examples, give priority to the guidance given in the present invention, or according to the experimental manual or routine conditions in this field, or according to the conditions suggested by the manufacturer, or refer to the existing conditions in this field. known experimental methods.

[0127] In the following specific examples, the measurement parameters related to raw material components may have slight deviations within the weighing accuracy range unless otherwise specified. Involves temperature and time parameters, allowing for acceptable deviations due to instrumental test accuracy or operational accuracy.

[0128] In...

Embodiment 1

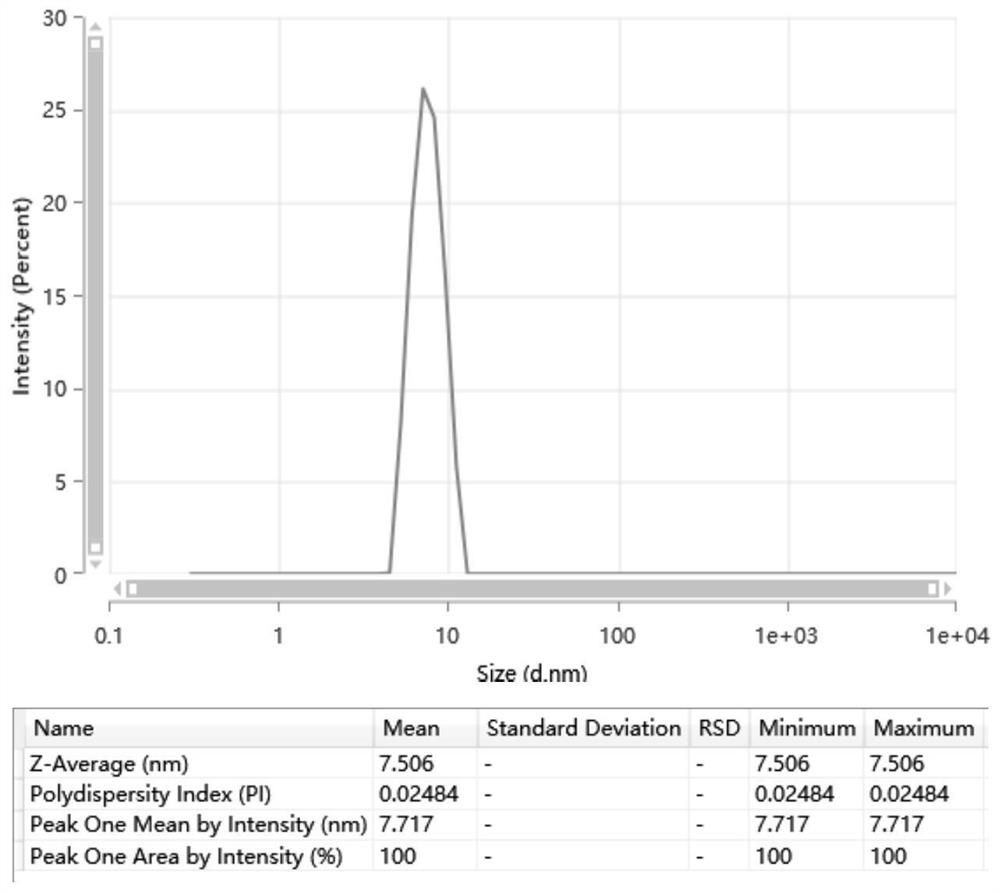

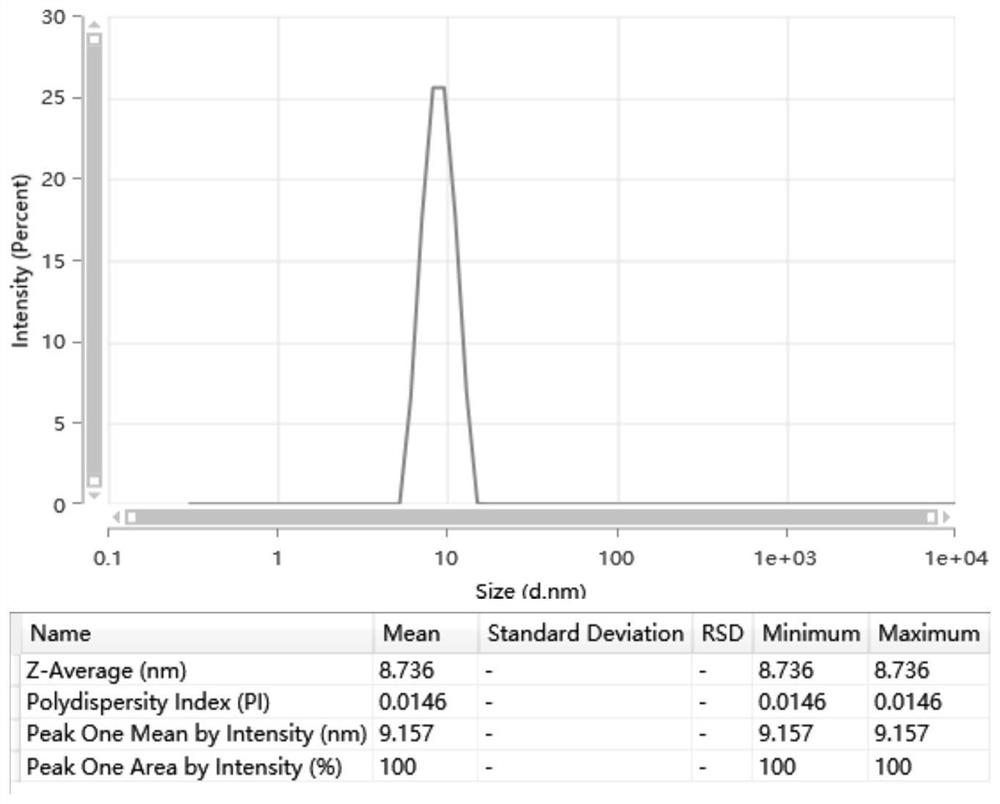

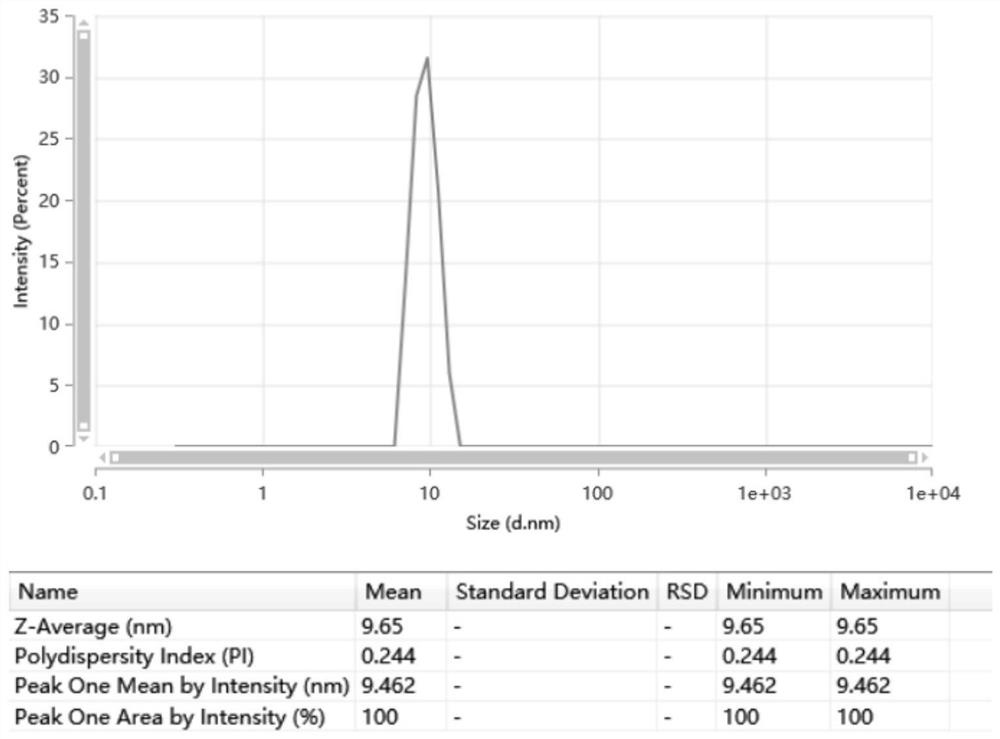

[0135] Sieve the calamine powder, the sieve mesh number is 50 mesh, add water, wherein the mass ratio of calamine: water is 1:5, wet ball milling with a ball mill, the mass ratio of calamine powder: zirconia beads is 1 :0.5, the ball milling time is 0.8h, and the ball milling speed is 240rpm to obtain nano calamine (the particle size is tested by a particle size analyzer, and parameters such as average particle size and polydispersity index can be measured). After the particle size test, the temperature Dry at 60°C for 12 hours, pass through a 200-mesh sieve, and set aside.

[0136] Blend dimethyl silicone rubber and nano calamine with an internal mixer, add vulcanizing agent 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, wherein silicone rubber: nano The mass ratio of calamine: vulcanizing agent is 100:0.2:0.8, and vulcanization is carried out to obtain nano calamine antibacterial silicone rubber. Among them, the blending temperature of the internal mixer is 28°C; the speed r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com