Pot for iron-aluminum combined induction cooker and manufacture method thereof

A composite electromagnetic, iron-aluminum technology, applied in the direction of special materials for cooking utensils, etc., can solve the problems of pot weight, easy to rust, etc., and achieve the effect of high production efficiency, high bonding strength, and easy mass industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

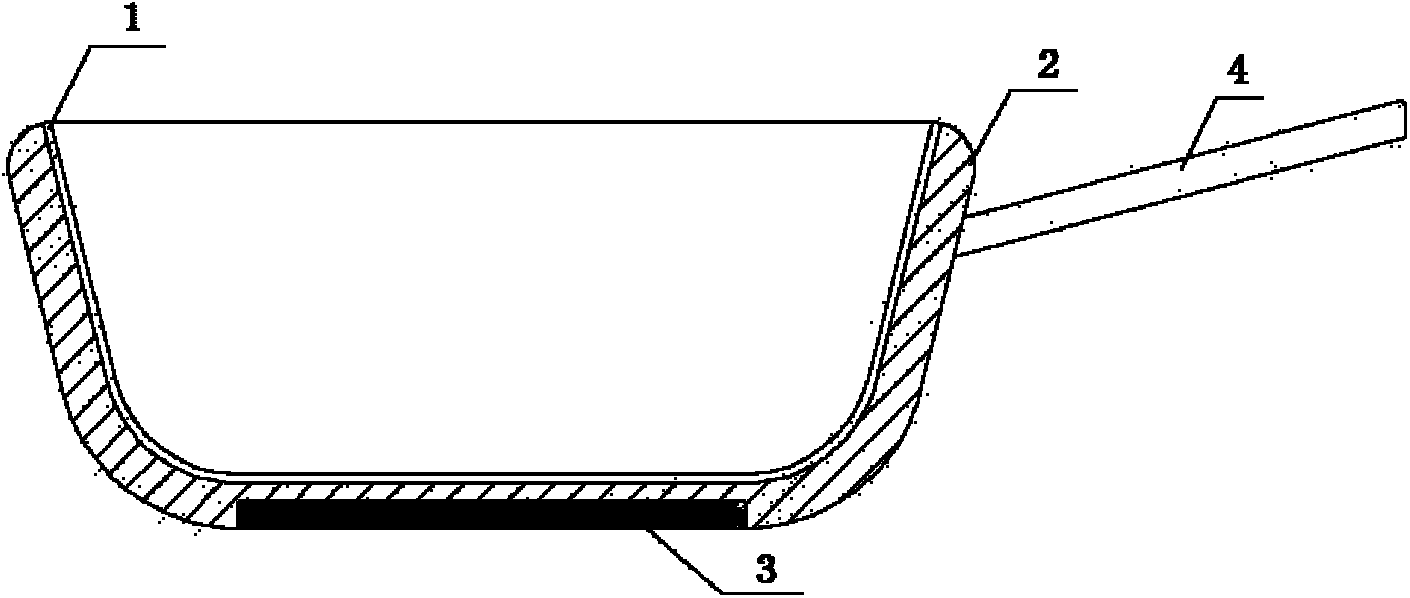

[0023] see figure 1 , the present embodiment provides the structure of a pot for an iron-aluminum composite induction cooker, including a pot body and a handle 4, the pot body is composed of pure iron plate 1 and pure aluminum plate 2, the pure iron plate 1 is the inner layer, and the pure aluminum plate 2 For the outer layer, the bottom of the pot body is embedded with a stainless steel plate 3.

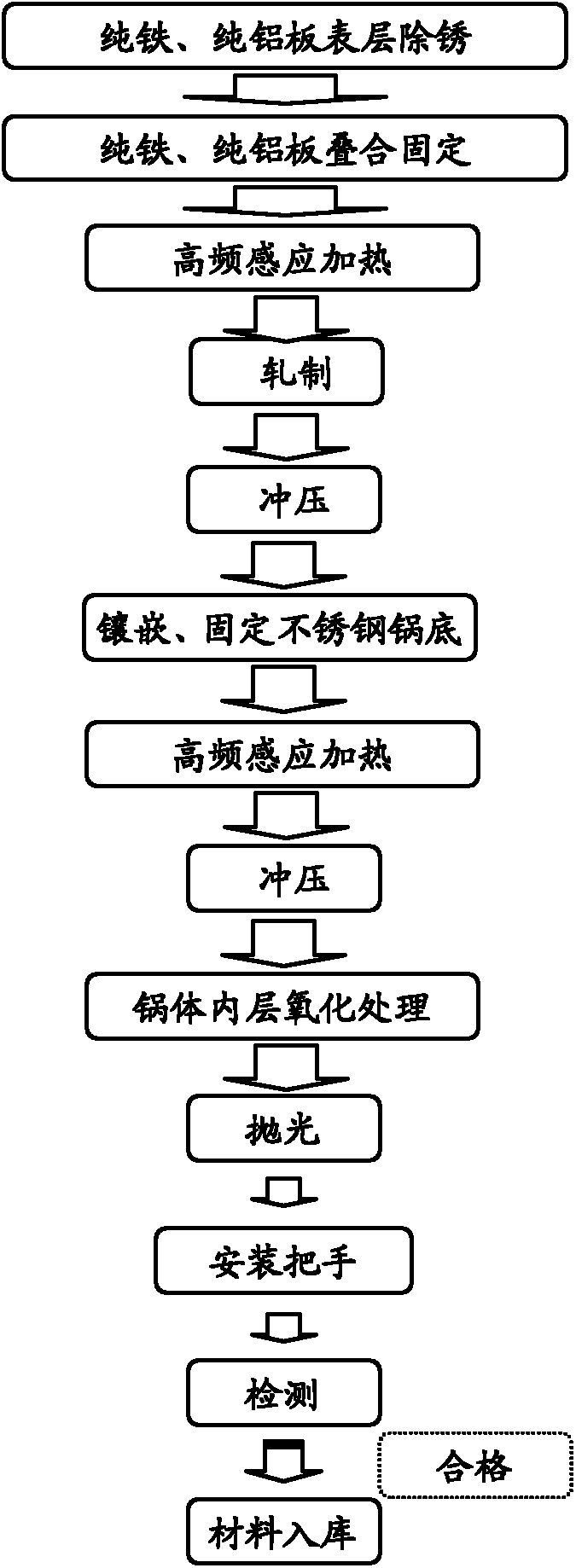

[0024] The preparation method adopts the method of hot rolling, and the pure iron plate and the aluminum plate are compounded, and then through rolling and stamping, a stainless steel plate is embedded on the outer bottom of the pot body.

[0025] The structure of this pot involves aluminum-pure iron composite and aluminum-stainless steel plate composite technology in the manufacturing process. Aluminum (aluminum alloy) steel composite plate (strip) refers to a bimetallic plate (strip) product that combines metal aluminum (or aluminum alloy) and steel plate (strip) through a specia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com