A kind of silicon-based ceramic micro-nano fiber thermal insulation felt and preparation method thereof

A nanofiber and ceramic microtechnology, applied in the field of material science and engineering, can solve problems such as the need for binders, and achieve the effects of low cost, overcoming preparation difficulties, and easy mass industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

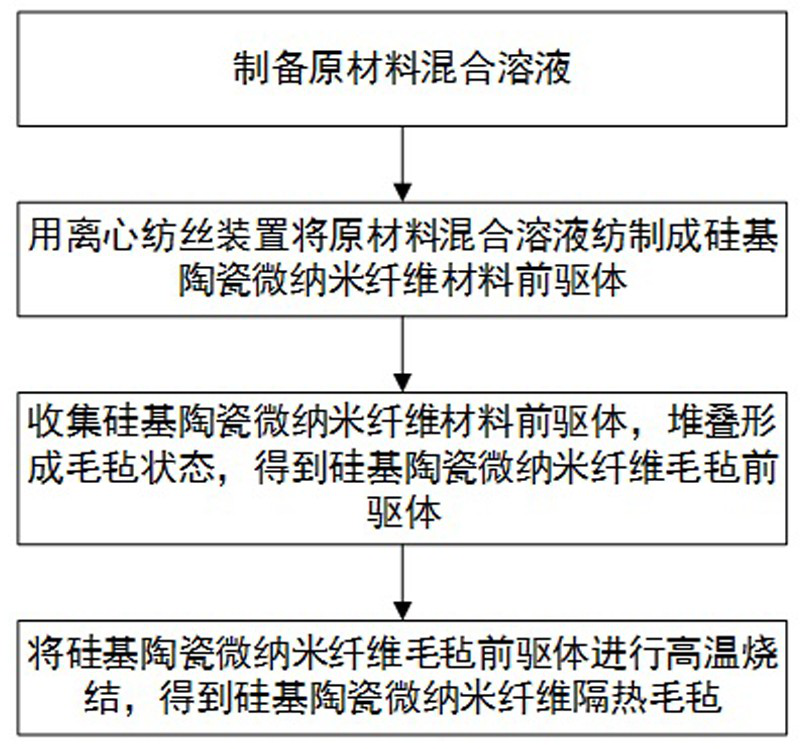

Method used

Image

Examples

Embodiment 1

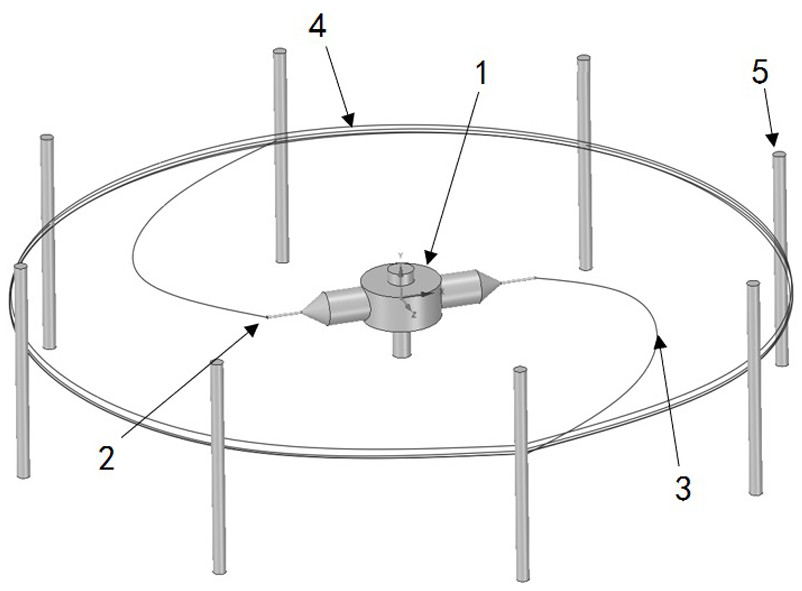

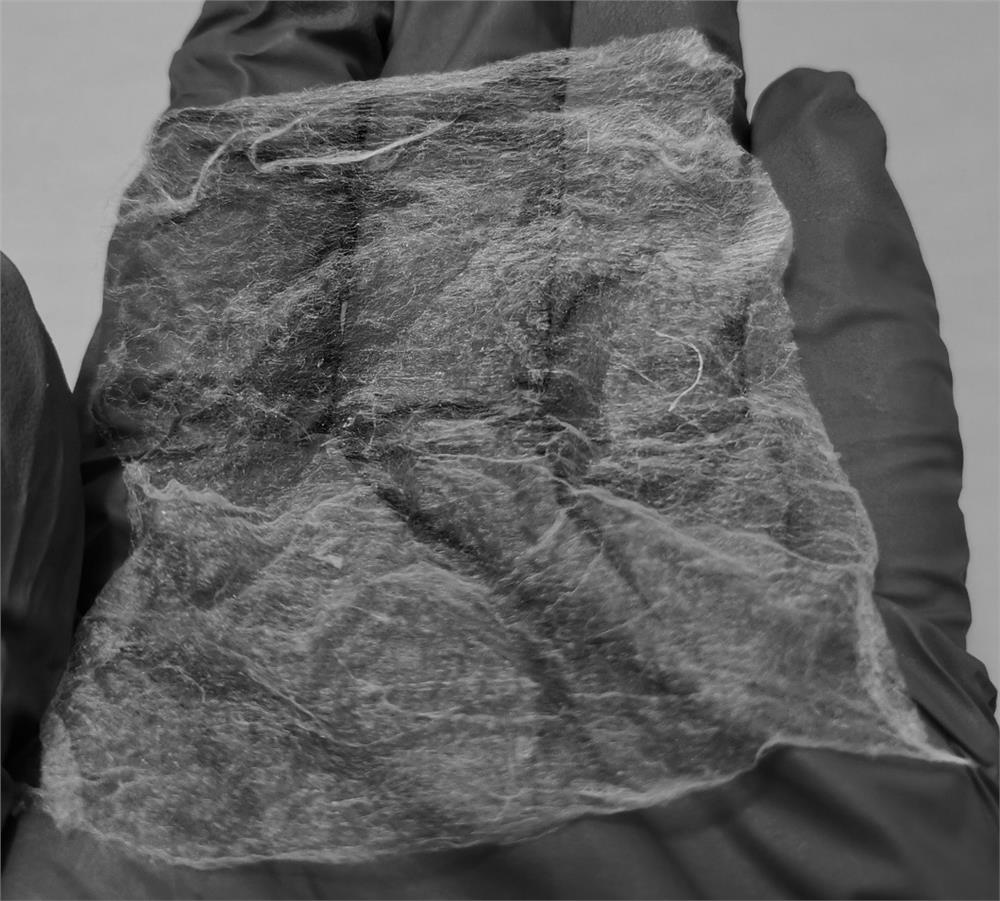

[0061] In this embodiment, the specific preparation method is as follows: firstly prepare a mixed solution of raw materials, firstly seal tetraethyl silicate, tetrabutyl titanate, water and acetic acid in a mass ratio of 1:0.5:9:0.01 Mix evenly in the bottle, then add the PEO powder particles into the uniformly mixed solution and continue to seal and stir for 8 hours. The nanometer graphene oxide sheet accounts for 3% of the weight of the organic salt, and the liquid sodium silicate accounts for 2% of the weight of the organic salt. Extract a certain amount of uniform raw material mixed solution and inject it into the liquid storage tank, control the rotational speed of the motor to 4000 rpm, and use the centrifugal force generated by the high-speed rotation of the liquid storage tank to spray the solution from the small needle installed on the liquid storage tank. The resulting solution is rapidly stretched in the air to form viscous solution filaments, and the solvent in the...

Embodiment 2

[0064] In this embodiment, the specific preparation method is as follows: firstly prepare a mixed solution of raw materials, firstly put tetraethyl silicate, tin tetrachloride, water and acetic acid in a sealed bottle according to the mass ratio of 1:0.3:11:0.01 Mix well, then add the PEO powder particles into the uniformly mixed solution and continue to seal and stir for 8 hours, the mass percentage of PEO in the raw material mixed solution is 8%, and then add nano graphene oxide sheets and liquid sodium silicate. The nanometer graphene oxide sheet accounts for 4% of the weight of the organic salt, and the liquid sodium silicate accounts for 3% of the weight of the organic salt. Extract a certain amount of uniform raw material mixed solution and inject it into the liquid storage tank, control the rotational speed of the motor to 8000rpm, and use the centrifugal force generated by the high-speed rotation of the liquid storage tank to spray the solution from the small needle ins...

Embodiment 3

[0067] In this embodiment, the specific preparation method is as follows: firstly prepare a mixed solution of raw materials, first put tetraethyl silicate, water, ethanol and acetic acid in a sealed bottle in a mass ratio of 1:0.2:11:1:0.01 Mix evenly, then add the PVA powder particles into the mixed solution, continue to seal and stir for 2 hours under the condition of a water bath at 80 ° C, the mass percentage of PVA in the raw material mixed solution is 30%, and then add nano graphene oxide sheets and liquid sodium silicate, the nano graphene oxide sheet accounts for 4% by weight of the organic salt, and the liquid sodium silicate accounts for 5% by weight of the organic salt. Extract a certain amount of uniform raw material mixed solution and inject it into the liquid storage tank, control the rotational speed of the motor to 8000rpm, and use the centrifugal force generated by the high-speed rotation of the liquid storage tank to spray the solution from the small needle in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com