Design method of lithium ion battery structure

A technology of lithium ion battery and design method, applied in secondary battery, non-aqueous electrolyte battery, electrolyte battery manufacturing and other directions, can solve problems such as low energy density and safety, achieve easy mass industrial production, weaken internal short circuit hidden danger, The effect of solving security problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

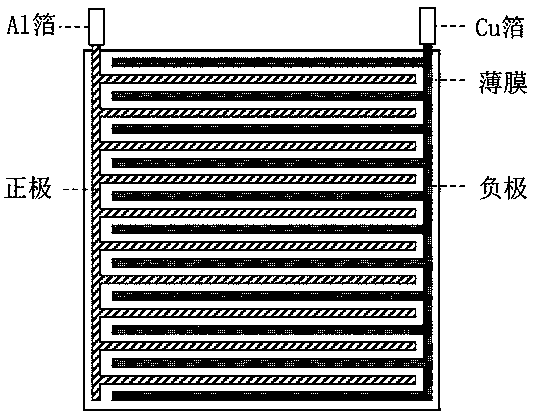

[0032] Such as figure 1 As shown, the schematic diagram of the cell obtained in this example uses a cellulose separator as a thin film separating the positive and negative materials, coats the positive and negative materials in a cross shape on the separator, and uses the electrolyte as the medium for lithium ion transmission.

[0033] A "planar" structure design method of a diaphragm / electrolyte / positive electrode / negative electrode of the present invention, according to the following steps:

[0034] (1) The nickel-cobalt-manganese ternary cathode material is figure 1 The shape shown is coated on both sides of the cellulose diaphragm, and dried at 80°C for 12 hours to solidify;

[0035] (2) The graphite anode material is figure 1 The shape shown is coated on both sides of the cellulose diaphragm, and dried at 100°C for 12 hours to solidify;

[0036] (3) The above materials are immersed in the electrolyte and packaged.

Embodiment 2

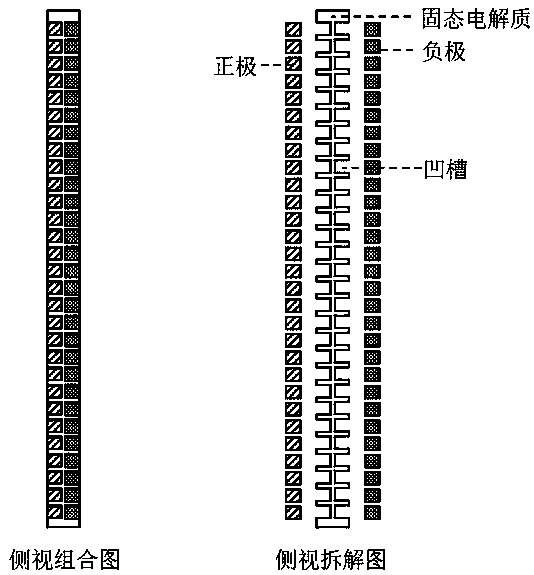

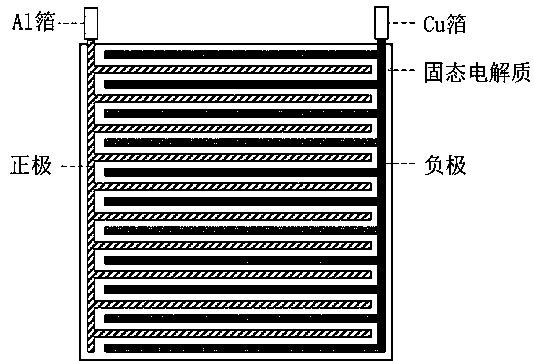

[0038] A "planar" structure design method of a solid electrolyte / positive electrode / negative electrode of the present invention, such as figure 2 It is a schematic diagram of the front view of the battery cell obtained in this embodiment, relying on the solid electrolyte as the separator separating the positive and negative electrode materials and the medium for lithium ion transmission; image 3 The schematic side view of the cell obtained in this example relies on the solid electrolyte as the separator separating the positive and negative electrode materials and the medium for lithium ion transmission.

[0039] Specifically follow the steps below:

[0040] (1) The nickel-cobalt-manganese ternary cathode material is figure 2 , image 3 The shape shown is filled into the empty tank of polyoxyethylene (PEO)-based electrolyte, and dried at 80°C for 12 hours to cure;

[0041] (2) The graphite anode material is figure 2 , image 3 The shape shown is filled into the polyoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com