Method for preparing dry rice flour by using curdlan

A dry rice flour and a technology for rice flour, applied in the field of preparing dry rice flour, can solve the problems of insufficient toughness, easy to break, high brittleness, and achieve high commercial value, improve strength, elasticity and chewiness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: utilize curdlan gum to prepare rice noodles

[0032] The preparation process of ground rice is carried out as follows:

[0033] (1) Wash and dry the indica rice and pulverize it, and pass through a 100-mesh sieve;

[0034] (2) Add curdlan gum CG-01 to the indica rice powder obtained in (1), and mix evenly; the addition amount of curdlan gum is 0.6% of the indica rice powder mass;

[0035] (3) Put the mixture obtained in (2) into a twin-screw extruder, and make rice noodles through gelatinization and extrusion; , the temperature in the third zone is 80°C, the temperature in the fourth zone is 95°C, and the temperature in the fifth zone is 80°C;

[0036] (4) After finishing the rice flour obtained in (3), aging at 20° C. for 4 hours, and then drying at 60° C. for 1 hour to obtain a dried rice flour product.

Embodiment 2

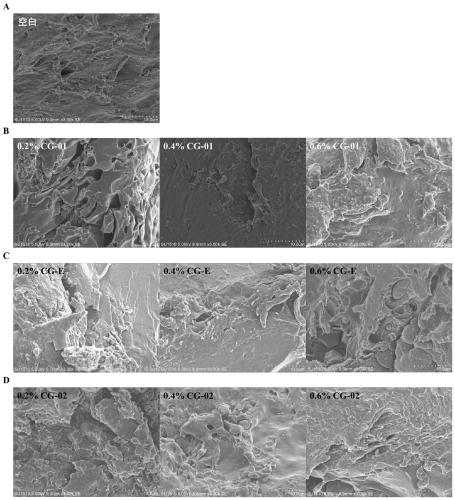

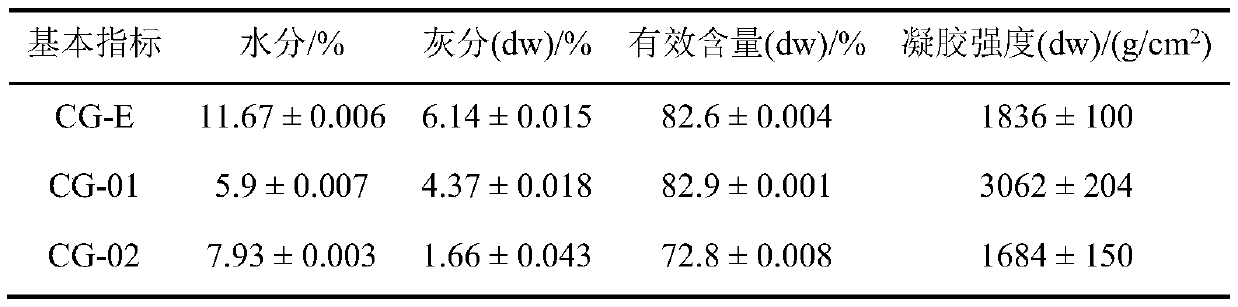

[0037] Embodiment 2: the influence of curdlan gum on the quality of rice noodles

[0038] Prepare rice noodles with reference to the method of Example 1, the difference is: change the type and amount of curdlan gum, respectively: 0.2% CG-E, 0.4% CG-E, 0.6% CG-E, 0.2% CG-01, 0.4% %CG-01, 0.6% CG-01, 0.2% CG-02, 0.4% CG-02 and 0.6% CG-02, rice flour without curdlan gum was used as blank control, and other conditions were the same as in Example 1.

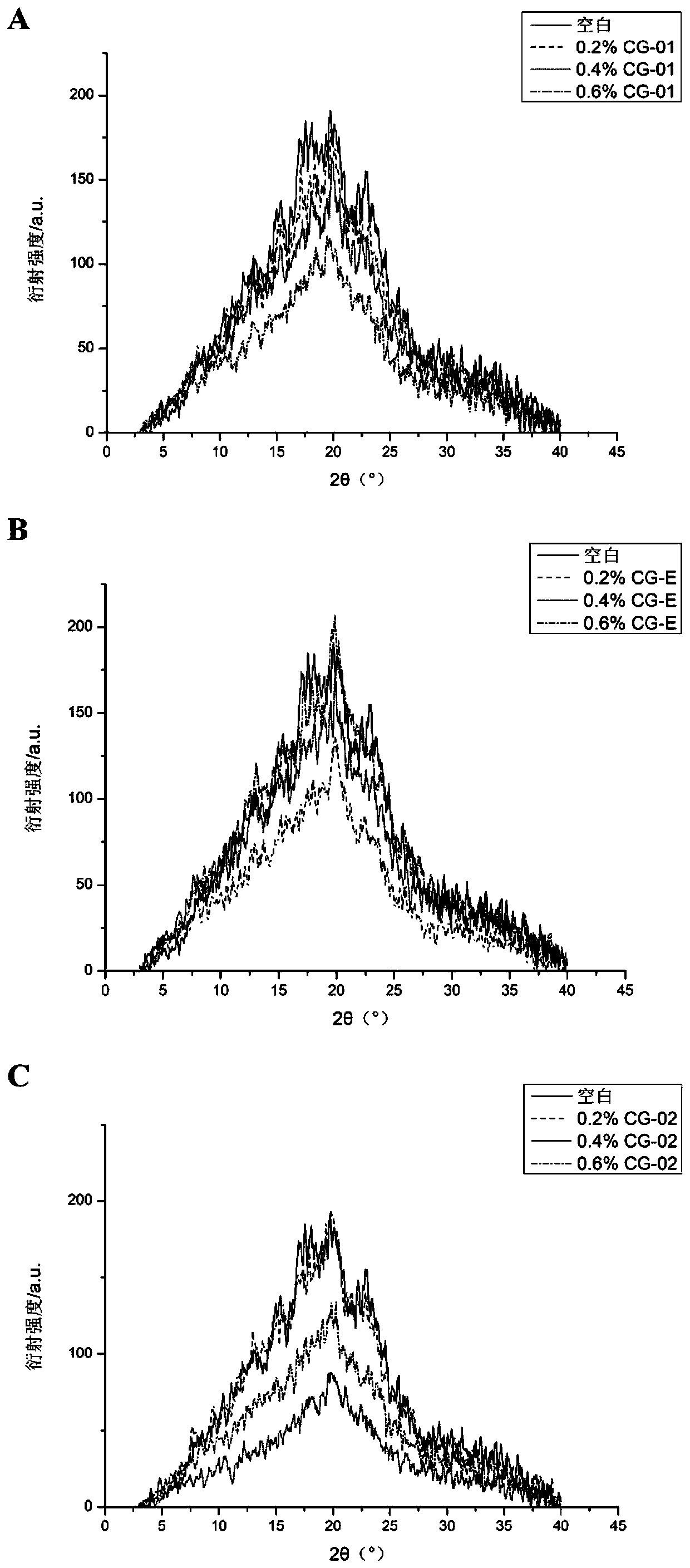

[0039] 1. Effect of curdlan gum on the pasting properties of rice flour RVA

[0040] The RVA gelatinization properties of rice flour are determined according to the following steps: Weigh 3g of indica rice powder into a lead bucket dedicated for RVA measurement, and add 0%, 0.2%, 0.4%, and 0.6% of three curdlan gums (relative to the mass of indica rice powder) and 25g of water, mix well. The viscosity of rice flour was measured with an RVA meter. The test method is in accordance with the national standard GB / T 24852-2010. Using th...

Embodiment 3

[0069] Embodiment 3: Compound curdlan gum on the influence of key quality of rice noodles

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com