An organic/inorganic ferroelectric composite material with ultra-high dielectric constant, its preparation method and application

A composite material and dielectric constant technology, applied in the direction of electrolytic capacitors, capacitor electrolytes/absorbents, circuits, etc., can solve problems such as difficulty in meeting conventional circuit requirements, complex processes, and comparable dielectric properties, and achieve easy mass industrialization The effect of simple production and operation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

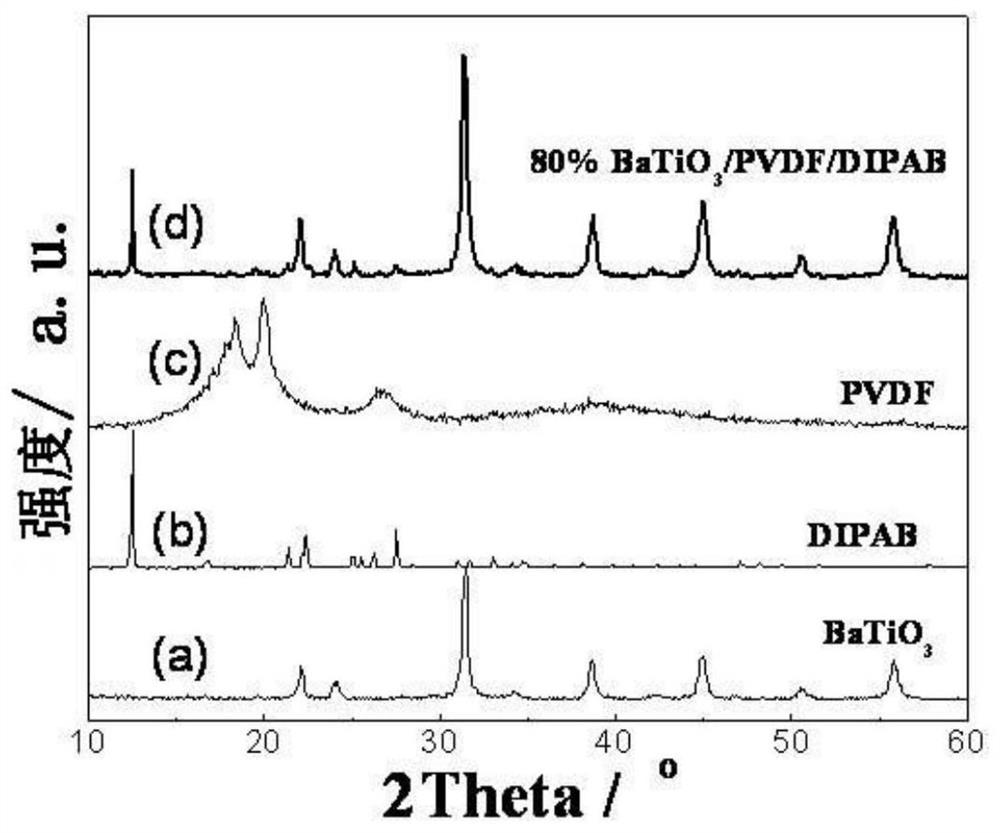

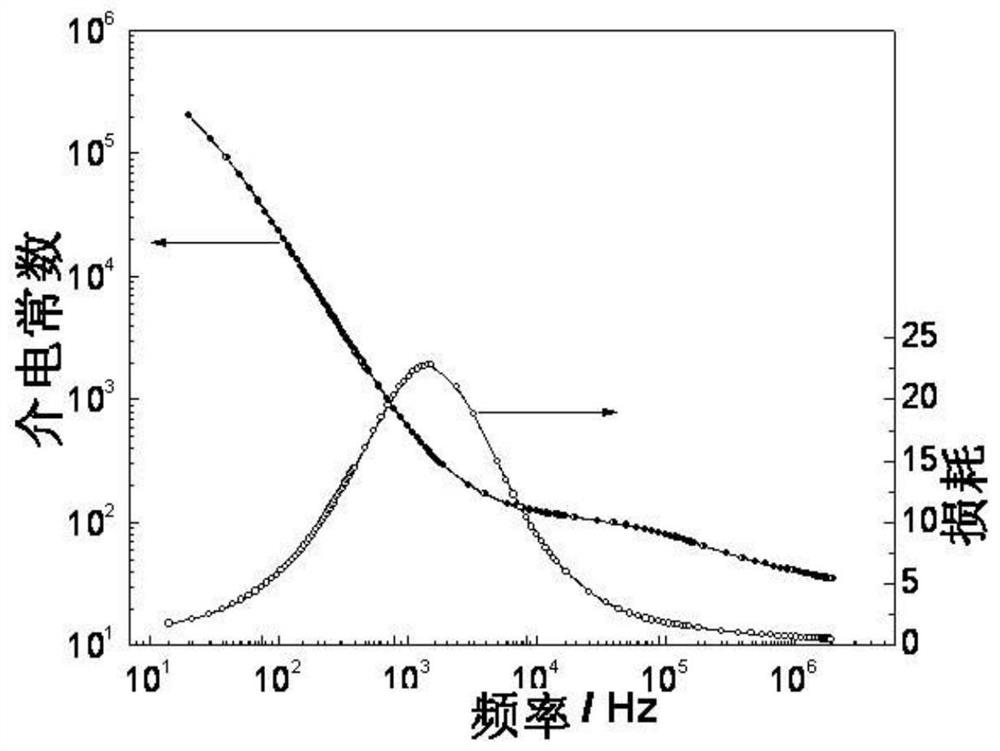

[0046] Weigh 0.2g PVDF and 0.2g DIPAB into a beaker, then add 20ml of absolute ethanol, and stir vigorously to obtain a clear PVDF / DIPAB mixed solution as an organic matrix solution. Then add 1.6g of BaTiO to the solution 3 Nano powder. Add a layer of plastic wrap on the beaker, after ultrasonic vibration for 30min, BaTiO 3 The powder was suspended in an absolute ethanol solution of PVDF and DIPAB. After removing the plastic wrap, the beaker was placed in a drying oven at 80°C for 24 hours to dry to obtain a white composite material powder. Its XRD such as figure 1 In (d) shown. It can be seen that in the XRD of the composite material powder, the XRD diffraction peaks of the three ferroelectrics exist at the same time, and the peak of the PVDF polymer is weaker, which is determined by its own crystallization status and its content is low. The ultra-high dielectric constant composite material powder is placed between two layers of aluminum foil, and pressed at room temperat...

Embodiment 2

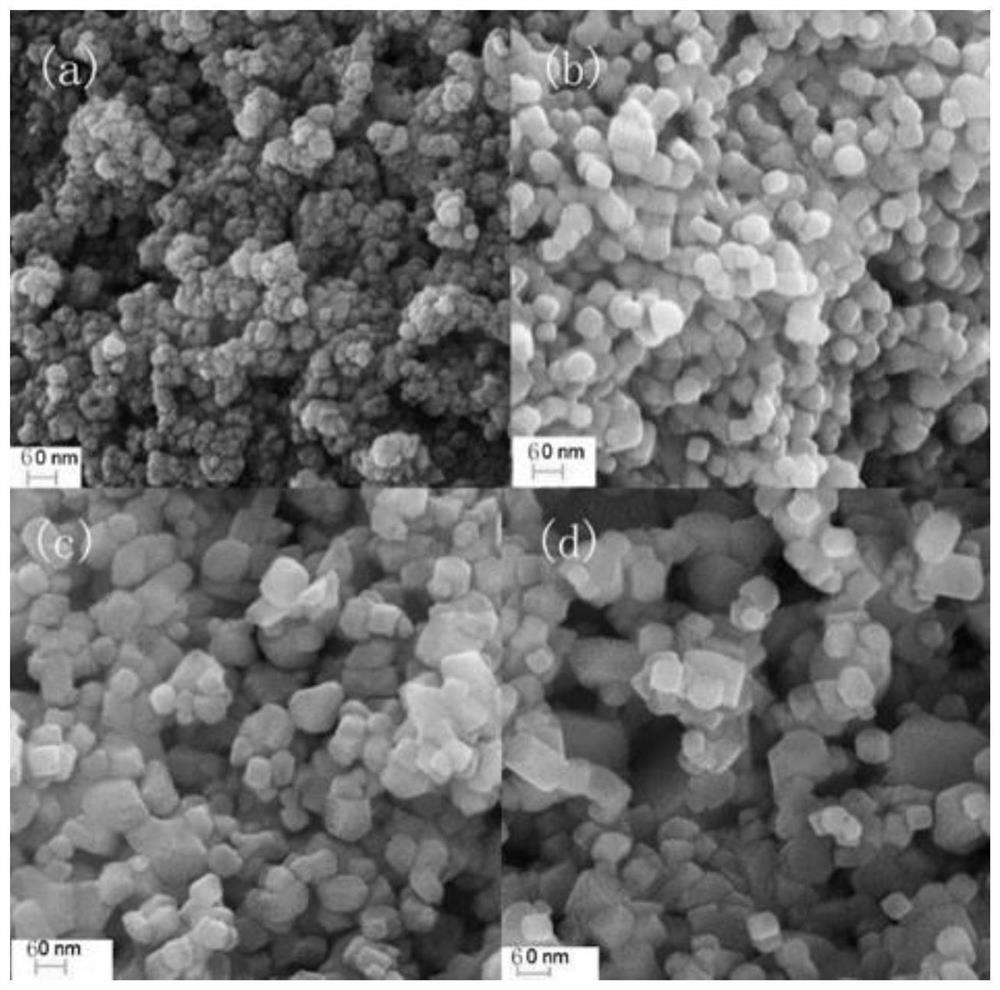

[0050] Nano BaTiO used 3 Powder, DIPAB and PVDF are the same as in Example 1. Nano-BaTiO obtained by direct solution synthesis 3 The powder was pre-fired at 800°C for 2 hours to make it ferroelectric, from figure 2 It can be seen that the size of the powder particles increases with the increase of the treatment temperature for the three samples with different treatment temperatures. For BaTiO 3 Nanoparticles, the scanning electron microscope SEM photo of this example is as follows figure 2 In (b) shown. Weigh 0.2g of PVDF and 0.2g of DIPAB into a beaker, then add 20ml of absolute ethanol, and stir vigorously to obtain a clear PVDF / DIPAB mixed solution as an organic matrix solution. Then add 1.6g of BaTiO pre-fired at 800°C to the solution 3 Nano powder. Add a layer of plastic wrap on the beaker, after ultrasonic vibration for 30min, BaTiO 3 The powder was suspended in an absolute ethanol solution of PVDF and DIPAB. After removing the plastic wrap, the beaker was pla...

Embodiment 3

[0052] Nano BaTiO used 3 Powder, DIPAB and PVDF are the same as in Example 1. Nano-BaTiO obtained by direct solution synthesis 3 The powder was pre-fired at 800°C for 2 hours. Weigh 0.3g PVDF and 0.3g DIPAB into a beaker, then add 20ml of absolute ethanol, and stir vigorously to obtain a clear PVDF / DIPAB mixed solution as an organic matrix solution. Then add 1.4g of BaTiO pre-fired at 800°C to the solution 3 Nano powder. Add a layer of plastic wrap on the beaker, after ultrasonic vibration for 30min, the BaTiO 3 The powder was suspended in an absolute ethanol solution of PVDF and DIPAB, and after the plastic wrap was removed, the beaker was placed in a drying oven at a temperature of 80°C for 24 hours to obtain a white composite material powder. The ultra-high dielectric constant composite material powder is placed between two layers of aluminum foil, and pressed into a required sheet with a pressure of 100 MPa, wherein the aluminum foil is used as the electrode material....

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com