Composite material with ultra-high dielectric constant, and preparation method and application thereof

A dielectric constant and composite material technology, applied in chemical instruments and methods, circuits, capacitors, etc., can solve problems such as difficulty in chip capacitors and complicated manufacturing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

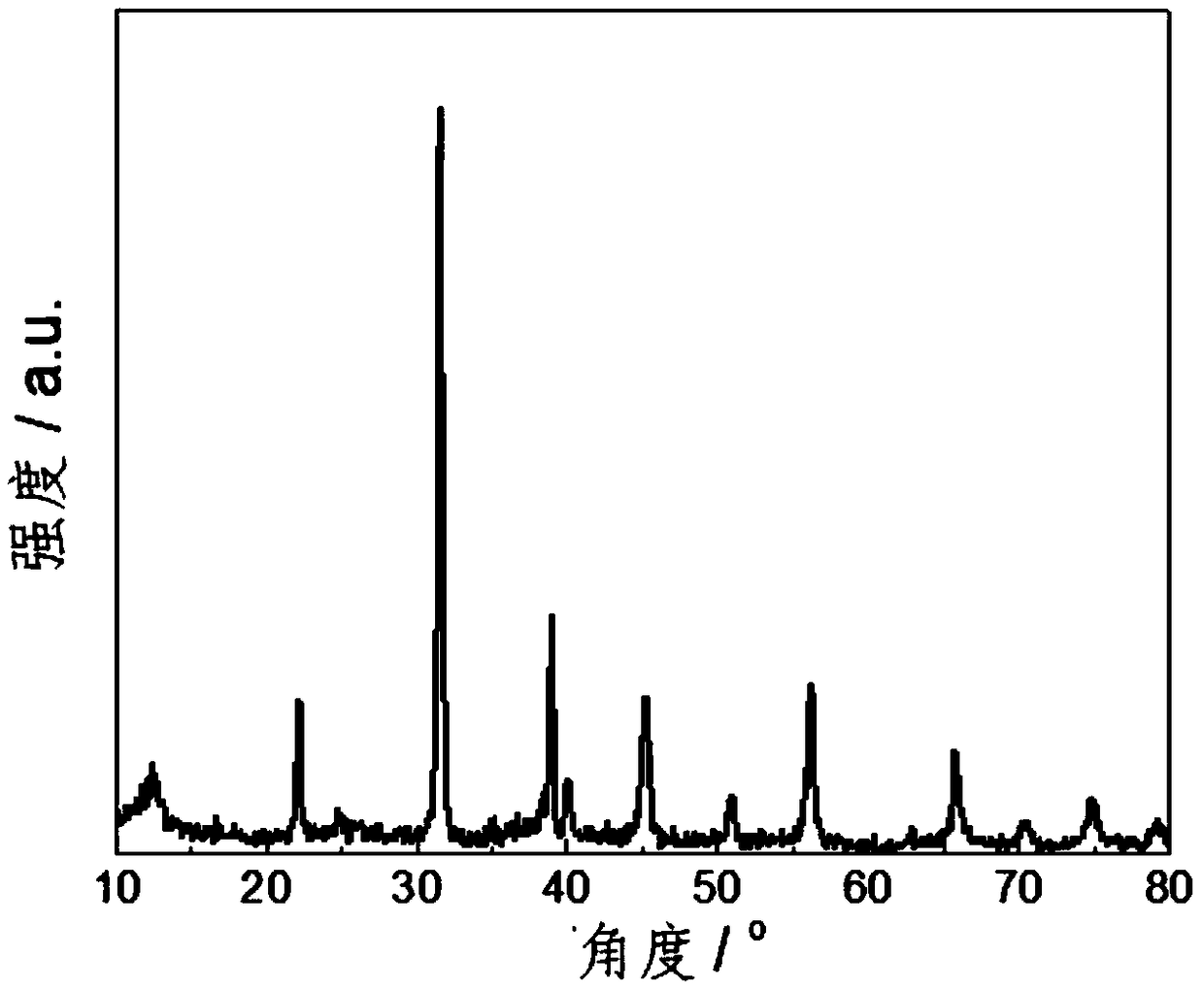

[0057] Composite materials with ultrahigh dielectric constant were prepared by chemical liquid phase precipitation, in which MnO 2 The synthesis of according to the chemical reaction equation:

[0058] MnSO 4 +H 2 o 2 +2NaOH=MnO 2 +2H 2 O+Na 2 SO 4

[0059] To be done.

[0060] The specific operation is as follows:

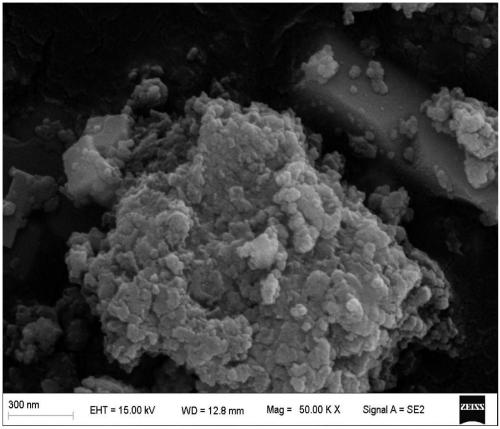

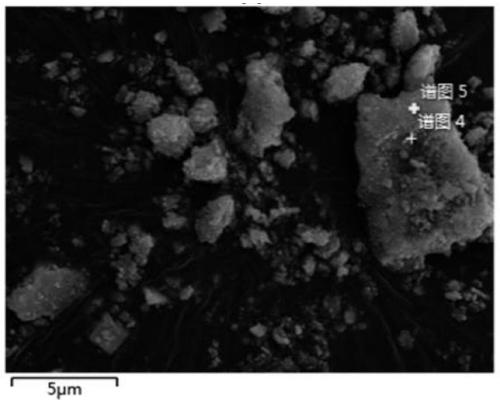

[0061] (1) First, 4.66g BaTiO 3 powder in H 2 Heat treatment at 900°C in air for 8 hours to make it semi-conductive.

[0062] (2) The composite material with pn junction was obtained by in situ synthesis. Weigh 1.6g NaOH and put it into a beaker, add 200ml deionized water to dissolve; 3 The powder was transferred to the prepared NaOH solution, stirred vigorously and heated to 60°C as the base liquid. Weigh 3.38gMnSO 4 ·H 2 O, put it into a small beaker, add 50mlH 2 O and 5ml 30% HO 2 o 2 Let it dissolve to form a titration solution. Add the titrant solution dropwise to the base solution, keep at 60°C and stir vigorously. After the titration is ...

Embodiment 2

[0070]Composite materials with ultrahigh dielectric constant were prepared by chemical liquid phase precipitation, in which MnO 2 The synthesis of according to the chemical reaction equation:

[0071] 2KMnO 4 +4NaOH+3MnSO 4 =5MnO 2 +2H 2 O+2Na 2 SO 4 +K 2 SO 4

[0072] To be done.

[0073] (1), first 4.66gBaTiO 3 powder in H 2 Heat treatment at 900°C for 8 hours in air.

[0074] (2) The composite material with pn junction is obtained by in-situ synthesis method. Weigh 1.58g KMnO 4 and 0.8gNaOH into a beaker, add 200mlH 2 O dissolved, the semiconducting BaTiO 3 The powder was transferred to the prepared above solution, vigorously stirred and heated to 70°C as the base liquid. Weigh 2.54g MnSO 4 ·H 2 O, put it into a small beaker, add 50ml H 2 O dissolves it to form a titrant. The titration solution was added dropwise to the base solution, kept at 70°C and vigorously stirred, and a dark brown precipitate was obtained after the titration was completed. After ...

Embodiment 3

[0077] Composite materials with ultrahigh dielectric constant were prepared by chemical liquid phase precipitation, in which MnO 2 The synthesis of according to the chemical reaction equation:

[0078] MnSO 4 +H 2 o 2 +2NaOH=MnO 2 +2H 2 O+Na 2 SO 4 To be done.

[0079] The specific operation is as follows:

[0080] (1) First, 3.07g BaTiO 3 powder in H 2 Heat treatment at 900°C in air for 8 hours to make it semi-conductive.

[0081] (2) The composite material with pn junction was obtained by in situ synthesis. Weigh 1.6g NaOH and put it into a beaker, add 200ml deionized water to dissolve; 3 The powder was transferred to the prepared NaOH solution, stirred vigorously and heated to 60°C as the base liquid. Weigh 3.38gMnSO 4 ·H 2 O, put it into a small beaker, add 50mlH 2 O and 5ml 30% HO 2 o 2 Let it dissolve to form a titration solution. Add the titrant solution dropwise to the base solution, keep at 60°C and stir vigorously. After the titration is completed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com