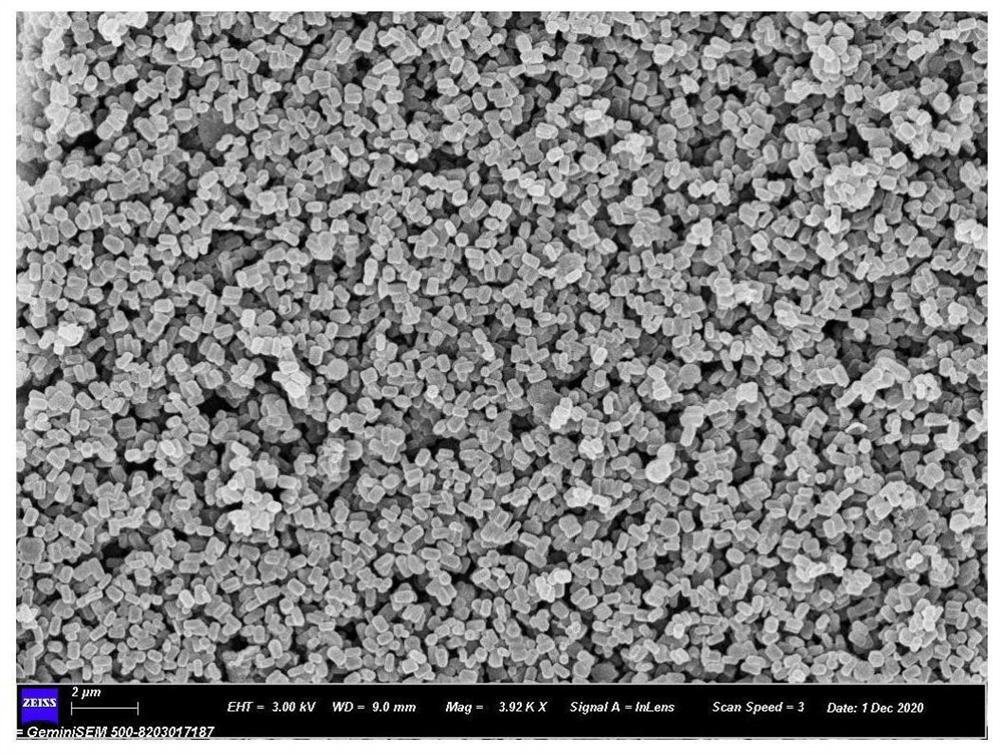

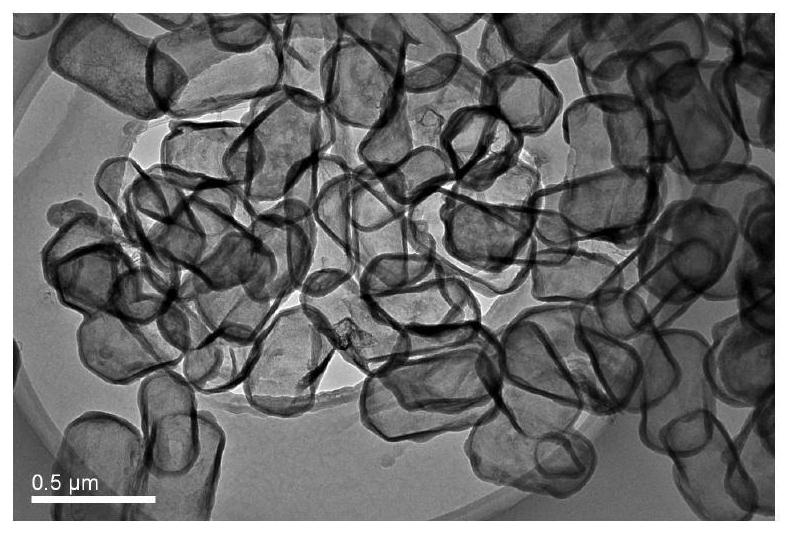

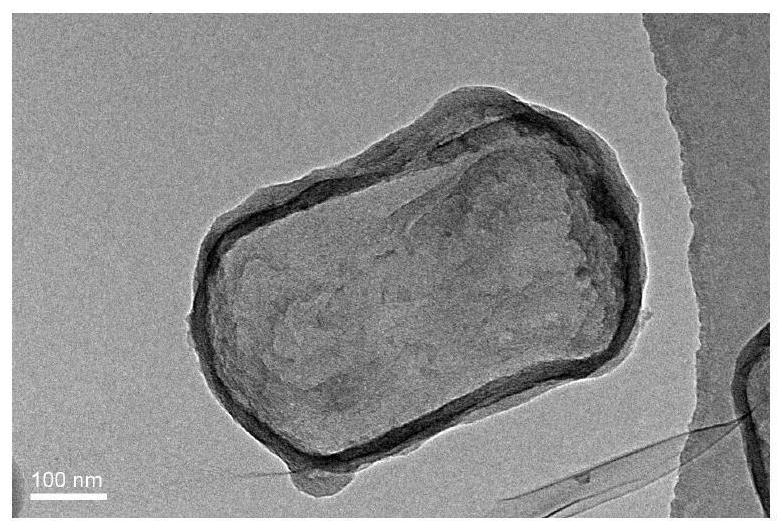

Preparation method of cylindrical titanium dioxide hollow particles

A titanium dioxide and hollow particle technology, which is applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of uneven particle size of titanium dioxide particles and low catalytic activity, and achieves a simple preparation process and improves catalytic activity. , the effect of widening the active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of cylindrical titanium dioxide hollow particles, comprising the steps of:

[0030] (1) Mix and stir 3-(4-toluene)propionic acid, p-methylphenylethylamine, polyethylene-polypropylene glycol and ultrapure water to form a transparent solution;

[0031] (2) Add organic titanate to the transparent solution of step (1), and stir;

[0032] (3) the solution of step (2) is placed in the reactor to react;

[0033] (4) After centrifugation, wash the white product;

[0034] (5) The product obtained in step (4) is transferred to the HCl / ethanol mixed solution, stirring;

[0035] (6) After centrifugal separation, the target product can be obtained by washing the precipitate.

[0036] Further, in step (1), in parts by weight, the addition of 3-(4-toluene)propionic acid is 0.3-0.7 parts, the addition of p-methylphenethylamine is 2-5.5 parts, polyethylene- The addition amount of polypropylene glycol is 0.1-0.4 part, and the addition amount of ultrapure water is...

Embodiment 1

[0045] This embodiment provides a method for preparing cylindrical titanium dioxide hollow particles, which specifically includes the following steps:

[0046] (1) In parts by weight, 0.3 parts of 3-(4-toluene) propionic acid, 2 parts of p-methylphenethylamine, 0.1 parts of polyethylene-polypropylene glycol and 10-20ml of ultrapure water are mixed and stirred for 3 -5 hours, a transparent solution is formed;

[0047] (2) Add 0.3 parts of butyl orthotitanate to the transparent solution in step (1), and stir for 3-10 minutes;

[0048] (3) Place the solution in an autoclave and treat it under hydrothermal conditions of 160-180 degrees for 24-48 hours.

[0049] (4) After centrifugation, the white product was washed three times with ethanol and deionized water.

[0050] (5) The product was transferred to a mixed solution of HCl / ethanol with a volume ratio of 1:10, and stirred overnight.

[0051] (6) After centrifugation, the target product can be obtained after washing the preci...

Embodiment 2

[0053] This embodiment provides a method for preparing cylindrical titanium dioxide hollow particles, which specifically includes the following steps:

[0054] (1) In parts by weight, 0.5 parts of 3-(4-toluene) propionic acid, 4 parts of p-methylphenethylamine, 0.3 parts of polyethylene-polypropylene glycol and 10-20ml of ultrapure water are mixed and stirred for 3 -5 hours, a transparent solution is formed;

[0055] (2) Add 0.6 parts of butyl orthotitanate to the transparent solution in step (1), and stir for 3-10 minutes;

[0056] (3) Place the solution in an autoclave and treat it under hydrothermal conditions of 160-180 degrees for 24-48 hours.

[0057] (4) After centrifugation, the white product was washed three times with ethanol and deionized water.

[0058] (5) The product was transferred to a mixed solution of HCl / ethanol with a volume ratio of 1:10, and stirred overnight.

[0059](6) After centrifugation, the target product can be obtained after washing the precip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com