Pyrolysis synthesis method of TiO2 nano-particles under control of electric field

A nanoparticle and synthesis method technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of increasing preparation cost and difficulty, cumbersome preparation methods, and inability to realize nanostructure control. Achieve the effects of easy mass industrial production, avoid grain growth and agglomeration, and avoid the introduction of toxic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

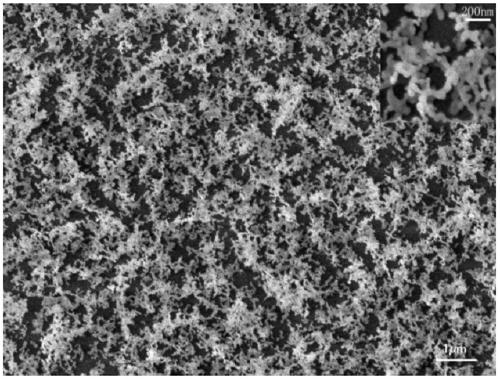

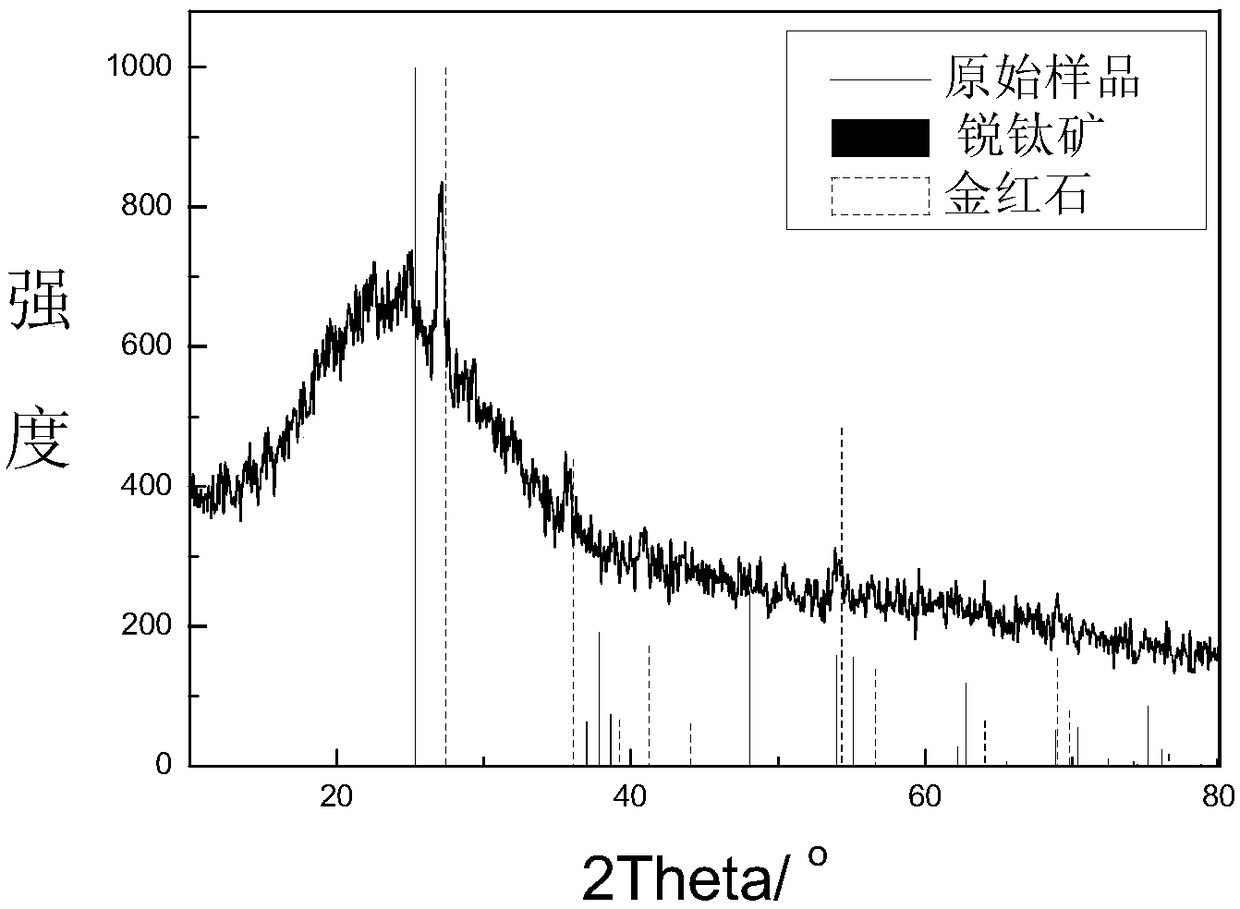

Embodiment 1

[0024] Dissolve 3.40 g of tetrabutyl titanate in 10 ml of absolute ethanol to obtain Injection A. Inhale liquid A into a 10ml syringe and place it on the syringe pump. Set the syringe pump to an infusion rate of 100 mL / min. Connect the needle of the syringe to the high-voltage electrode of the high-voltage power supply, the collector is a stainless steel mesh, and its electrode is grounded. The high-voltage power supply is set to +5000V, the syringe pump starts to run, and liquid A is ejected from the syringe under high pressure, and an alcohol lamp is placed under the ejection port to continuously heat and ignite the ejected liquid. At this time, the ejected liquid forms a nano-beam due to combustion to form an ejected flame, and the solid nano-particles formed by the flame are collected by a grounded collector. After the reaction is over, turn off the high-voltage power supply and the syringe pump, remove the collector, and directly obtain TiO 2 nanoparticles. Such as ...

Embodiment 2

[0026] Dissolve 3.40 g of titanium tetrachloride in 10 ml of acetone to obtain liquid A for injection. Inhale liquid A into a 10ml syringe and place it on the syringe pump. Set the syringe pump to an infusion rate of 100ml / min. Connect the needle of the syringe to the high-voltage electrode of the high-voltage power supply, the collector is a stainless steel mesh, and its electrode is grounded. The high-voltage power supply is set to +5000V, the syringe pump starts to run, and liquid A is ejected from the syringe under high pressure, and a drying oven is placed under the ejection port, and the heating temperature is 600°C, so that the ejected liquid is continuously heated and ignited. At this time, the ejected liquid forms a nano-beam due to combustion to form an ejected flame, and the solid nano-particles formed by the flame are collected by a grounded collector. After the reaction is over, turn off the high-voltage power supply and the syringe pump, remove the collector, a...

Embodiment 3

[0028] Dissolve 3.80 g of titanium isopropoxide in 20 ml of water to obtain liquid A for injection. Inhale liquid A into a 10ml syringe and place it on the syringe pump. Set the syringe pump to an infusion rate of 800ml / min. Connect the needle of the syringe to the high-voltage electrode of the high-voltage power supply, the collector is a stainless steel mesh, and its electrode is grounded. The high-voltage power supply is set to +7000V, the syringe pump starts to run, and liquid A is ejected from the syringe under high pressure, and an alcohol lamp is placed under the ejection port to continuously heat and ignite the ejected liquid. At this time, the ejected liquid forms a nano-beam due to combustion to form an ejected flame, and the solid nano-particles formed by the flame are collected by a grounded collector. After the reaction is over, turn off the high-voltage power supply and the syringe pump, remove the collector, and directly obtain TiO 2 nanoparticles. Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com