High length-diameter ratio silver nanowire and preparation method thereof

A silver nanowire, high aspect ratio technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve silver nanoparticles and nanowire aspect ratio is not enough to meet practical application, Silver nanowires are easily doped and the yield of silver nanowires is low, so as to achieve the effects of easy mass industrial preparation, good repeatability, and inhibition of the formation of silver particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

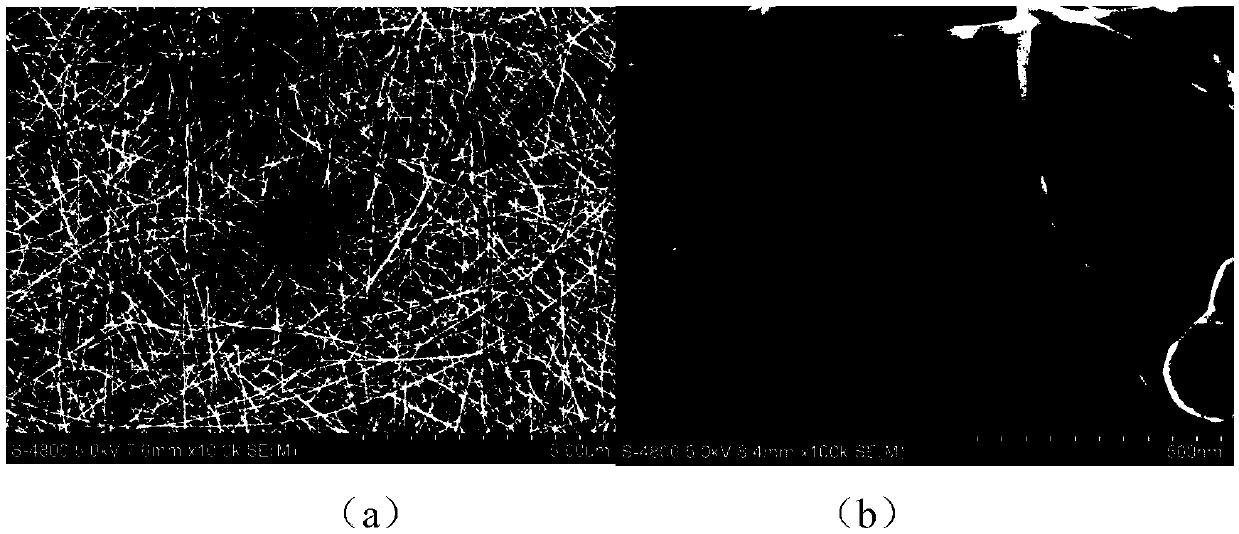

Embodiment 1

[0037] (1) Pretreatment of ethylene glycol solution: add anhydrous magnesium sulfate to the ethylene glycol solution, put it in an electronic moisture-proof cabinet and let it stand overnight, then distill under reduced pressure to obtain a dry ethylene glycol solution and place it in an electronic moisture-proof cabinet spare.

[0038] (2) Silver nitrate pretreatment: Silver nitrate is sieved with a 16-mesh stainless steel screen to remove large particles therein.

[0039] (3) Prepare the ethylene glycol solution of PVP: Weigh the powdered PVP, dissolve it in the ethylene glycol that has been pretreated in advance, put it on the heating plate and stir it to dissolve, the heating temperature is 120 °C, the concentration of the prepared solution 0.005g / mL. The molecular weight of the PVP used therein is between 55,000 and 1,300,000.

[0040] (4) Preparation of ethylene glycol solutions of A and B: weigh A and B respectively and dissolve them in ethylene glycol, put them on a ...

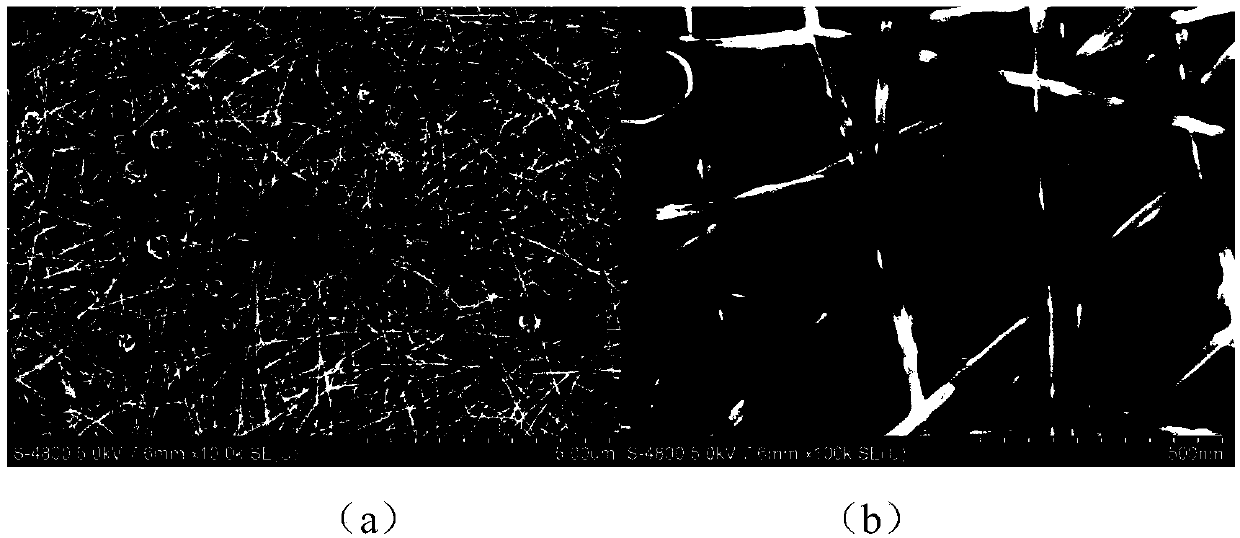

Embodiment 2

[0048] (1) Pretreatment of ethylene glycol solution: add anhydrous magnesium sulfate to the ethylene glycol solution, put it in an electronic moisture-proof cabinet and let it stand overnight, then distill under reduced pressure to obtain a dry ethylene glycol solution and place it in an electronic moisture-proof cabinet spare.

[0049] (2) Silver nitrate pretreatment: Silver nitrate is sieved with a 16-mesh stainless steel screen to remove large particles therein.

[0050] (3) Prepare the ethylene glycol solution of PVP: Weigh the powdered PVP, dissolve it in the ethylene glycol that has been pretreated in advance, put it on the heating plate and stir it to dissolve, the heating temperature is 120 °C, the concentration of the prepared solution It is 0.0055g / mL. The molecular weight of the PVP used therein is between 55,000 and 1,300,000.

[0051] (4) Preparation of ethylene glycol solutions of A and B: weigh A and B respectively and dissolve them in ethylene glycol, put the...

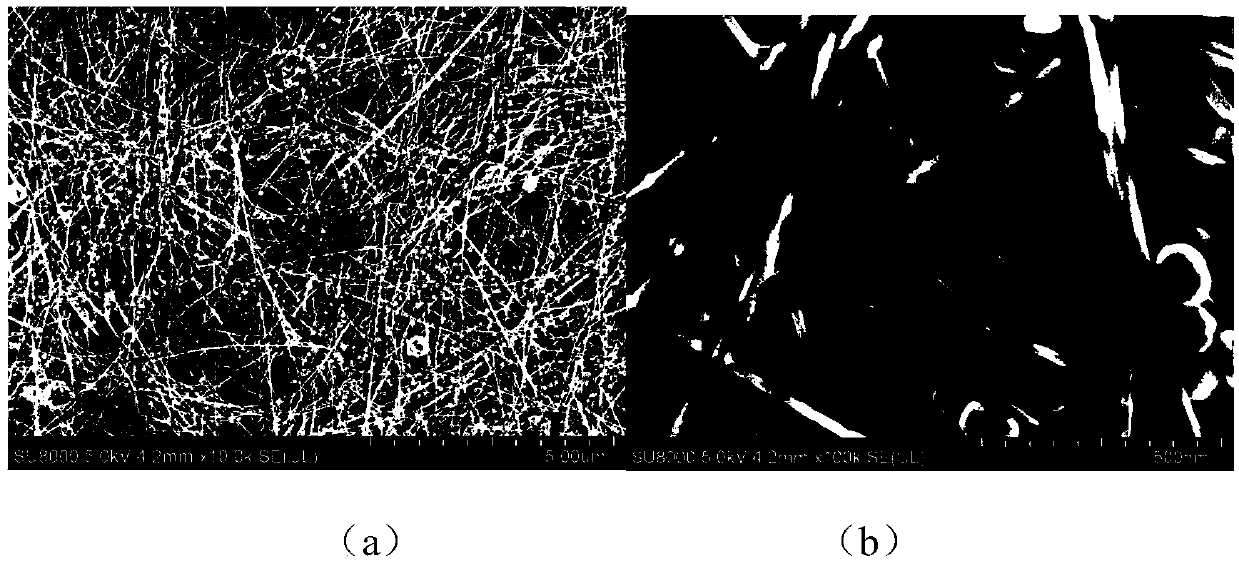

Embodiment 3

[0059] (1) Pretreatment of ethylene glycol solution: add anhydrous magnesium sulfate to the ethylene glycol solution, put it in an electronic moisture-proof cabinet and let it stand overnight, then distill under reduced pressure to obtain a dry ethylene glycol solution and place it in an electronic moisture-proof cabinet spare.

[0060] (2) Silver nitrate pretreatment: Silver nitrate is sieved with a 16-mesh stainless steel screen to remove large particles therein.

[0061] (3) Prepare the ethylene glycol solution of PVP: Weigh the powdered PVP, dissolve it in the ethylene glycol that has been pretreated in advance, put it on the heating plate and stir it to dissolve, the heating temperature is 120 °C, the concentration of the prepared solution 0.005g / mL. The molecular weight of the PVP used therein is between 55,000 and 1,300,000.

[0062] (4) Preparation of ethylene glycol solutions of A and B: weigh A and B respectively and dissolve them in ethylene glycol, put them on a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com