Thermal self-closing ceramic modified diaphragm and preparation method thereof

A self-closing and modified technology, applied to electrical components, electrochemical generators, circuits, etc., can solve problems such as powder dropping, affecting the performance of ceramic diaphragms, and poor uniformity of ceramic powder coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

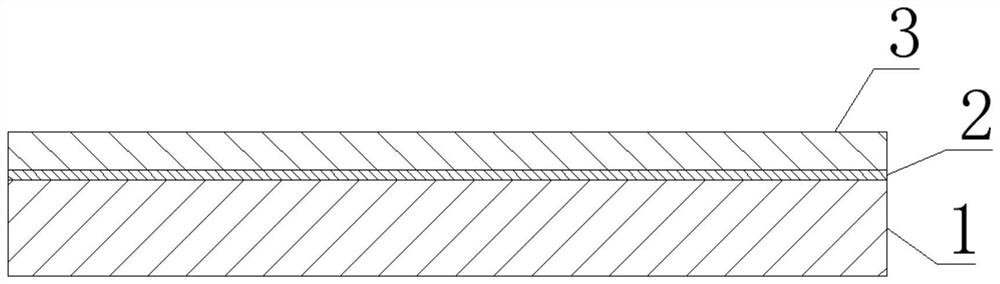

[0033] The preparation method of the self-closing ceramic modified diaphragm provided in this embodiment includes the following steps:

[0034] S1: Prepare thermal self-closing ceramic coating 3. Specifically, first prepare the ceramic particle premix, add 0.995kg of tetraethyl orthosilicate, 0.4975kg of nano-alumina and 0.4975kg of nano-titanium dioxide, and add 0.01kg of titanium The ester coupling agent is dispersed at a high speed with a stirrer at a speed of 130 rpm, and the dispersed ceramic particle premix is stirred for 25 minutes and then left to defoam. Then respectively add 0.2kg novolak epoxy acrylic resin, 0.003kg ultrafine sodium bicarbonate, 0.5kg acrylic resin, 7.297kg acrylic resin emulsion and stir to form thermal self-closing ceramic coating 3 total 10kg.

[0035] S2: The polyolefin separator substrate 1 is unwound.

[0036] S3: Corona treatment is performed on the coated surface of the polyolefin separator substrate 1 to form a corona-treated surface 2, an...

Embodiment 2

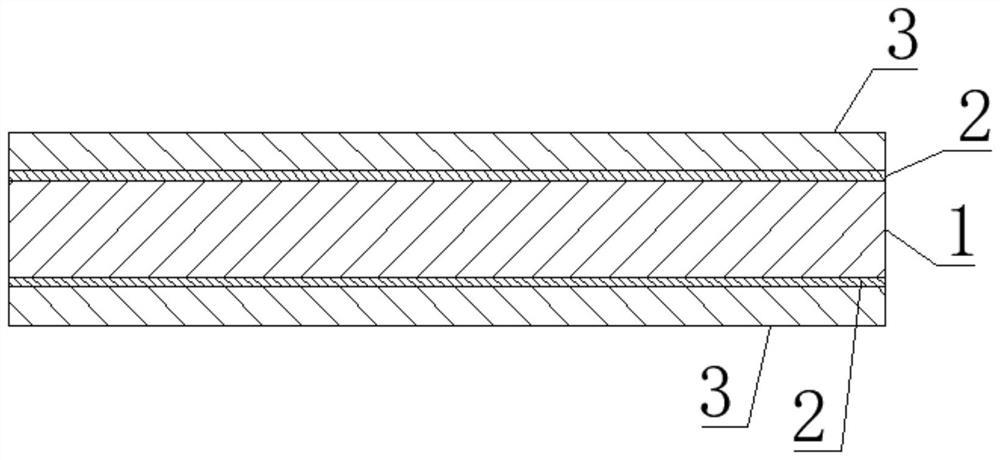

[0040] The preparation method of the self-closing ceramic modified diaphragm provided in this embodiment includes the following steps:

[0041] S1: Preparation of thermal self-closing ceramic coating 3. Specifically, first prepare a premixture of ceramic particles, add 1.14425kg of tetraethyl orthosilicate, 0.572125kg of nano-alumina and 0.572125kg of nano-titanium dioxide, and add 0.0115kg of titanium The ester coupling agent is dispersed at a high speed with a stirrer at a speed of 135 rpm, and the dispersed ceramic particle premix is stirred for 30 minutes and then left to defoam. Then respectively add 0.3kg novolac epoxy acrylic resin, 0.001kg ultrafine sodium bicarbonate, 0.2kg acrylic resin, 7.199kg polyurethane emulsion and stir to form thermal self-closing ceramic coating 3 total 10kg.

[0042] S2: The polyolefin separator substrate 1 is unwound.

[0043] S3: Corona treatment is performed on the coated surface of the polyolefin separator substrate 1 to form a corona...

Embodiment 3

[0047] The preparation method of the self-closing ceramic modified diaphragm provided in this embodiment includes the following steps:

[0048] S1: Preparation of thermal self-closing ceramic coating 3. Specifically, first prepare a premixture of ceramic particles, add 0.74625kg of tetraethyl orthosilicate, 0.373125kg of nano-alumina and 0.373125kg of nano-titanium dioxide, and add 0.0075kg of titanium The ester coupling agent is dispersed at a high speed with a stirrer at a speed of 125 rpm, and the dispersed ceramic particle premix is stirred for 20 minutes and then left to defoam. Then add 0.1kg of epoxy acrylic resin, 0.002kg of ultra-fine sodium bicarbonate, 0.3kg of acrylic resin, and 8.098kg of acrylic resin emulsion and stir to form a total of 10kg of thermal self-closing ceramic coating 3.

[0049] S2: The polyolefin separator substrate 1 is unwound.

[0050] S3: Corona treatment is performed on the coated surface of the polyolefin separator substrate 1 to form a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com