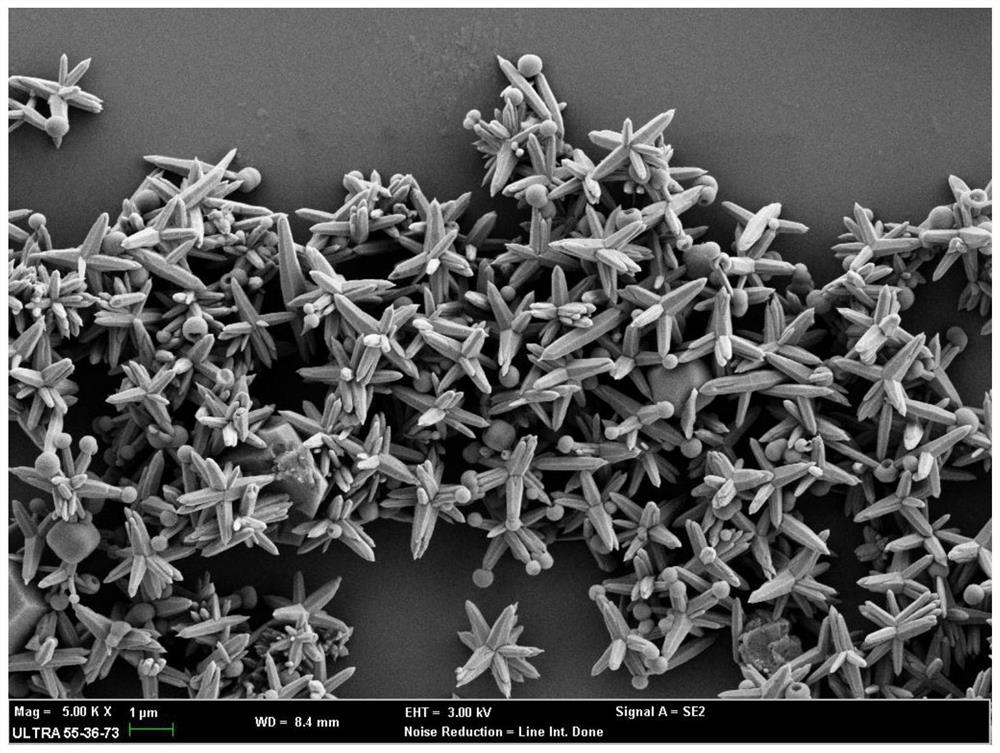

Titanium dioxide/zinc oxide heterojunction material with dendritic structure and preparation method thereof

A heterojunction and dendritic technology, which is applied in the field of titanium dioxide/zinc oxide heterojunction materials and preparation, can solve the problem of non-selectivity in degradation, achieve easy mass industrial production, simple preparation process, and improve electron-hole The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a titanium dioxide / zinc oxide heterojunction material with a dendritic structure, comprising the following steps:

[0028] 1) 1 part (weight ratio) of p-methylphenethylamine, 1 part (weight ratio) of polyethylene-polypropylene glycol and 10 ml of water were mixed and stirred for 3 hours to obtain solution 1;

[0029] 2) 1 part (by weight) of zinc nitrate (Zn(NO 3 ) 2 ·6H 2 0), 0.5 parts (weight ratio) of hexamethylenetetramine ((CH 2 ) 6 N 4 ) by adding 5ml ethylenediamine (C 2 h 8 N 2 ) solution to obtain solution 2;

[0030] 3) Add solution 2 to solution 1, add 0.2 parts (by weight) of butyl orthotitanate while stirring, and stir for 3 minutes;

[0031] 4) Place the solution obtained in step 3) in an autoclave, and treat it under 140 degree hydrothermal condition for 12 hours; after centrifugation, wash the white product 3 times with ethanol and deionized water to obtain a dendritic structure titanium dioxide / ZnO heterojunction materi...

Embodiment 2

[0034] A method for preparing a titanium dioxide / zinc oxide heterojunction material with a dendritic structure, comprising the following steps:

[0035] 1) 7 parts (weight ratio) of p-methylphenethylamine, 7.4 parts (weight ratio) of polyethylene-polypropylene glycol and 40 ml of water were mixed and stirred for 5 hours to obtain solution 1;

[0036] 2) 5 parts (by weight) of zinc nitrate (Zn(NO 3 ) 2 ·6H 2 0), 7 parts (weight ratio) of hexamethylenetetramine ((CH 2 ) 6 N 4 ) by adding 15ml ethylenediamine (C 2 h 8 N 2 ) solution, ultrasonic for 30 minutes to obtain solution 2;

[0037] 3) Add solution 2 to solution 1, add 0.7 parts (by weight) of butyl orthotitanate while stirring, and stir for 10 minutes;

[0038] 4) Place the solution obtained in step 3) in an autoclave, and treat it under hydrothermal conditions of 160 degrees for 48 hours; after centrifugation, wash the white product with ethanol and deionized water 3 times to obtain a dendritic structure titaniu...

Embodiment 3

[0040] A method for preparing a titanium dioxide / zinc oxide heterojunction material with a dendritic structure, comprising the following steps:

[0041] 1) 4 parts (weight ratio) of p-methylphenethylamine, 5 parts (weight ratio) of polyethylene-polypropylene glycol and 25ml of water were mixed and stirred for 4 hours to obtain solution 1;

[0042] 2) 3 parts (by weight) of zinc nitrate (Zn(NO 3 ) 2 ·6H 2 0), 4 parts (weight ratio) of hexamethylenetetramine ((CH 2 ) 6 N 4 ) by adding 10ml ethylenediamine (C 2 h 8 N 2 ) solution, ultrasonic for 20 minutes to obtain solution 2;

[0043] 3) Add solution 2 to solution 1, add 0.5 parts (weight ratio) of butyl orthotitanate while stirring, and stir for 6 minutes;

[0044] 4) Place the solution in an autoclave and treat it for 30 hours under 150 degree hydrothermal condition;

[0045] After centrifugation, the white product was washed three times with ethanol and deionized water to obtain a titanium dioxide / zinc oxide hetero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com