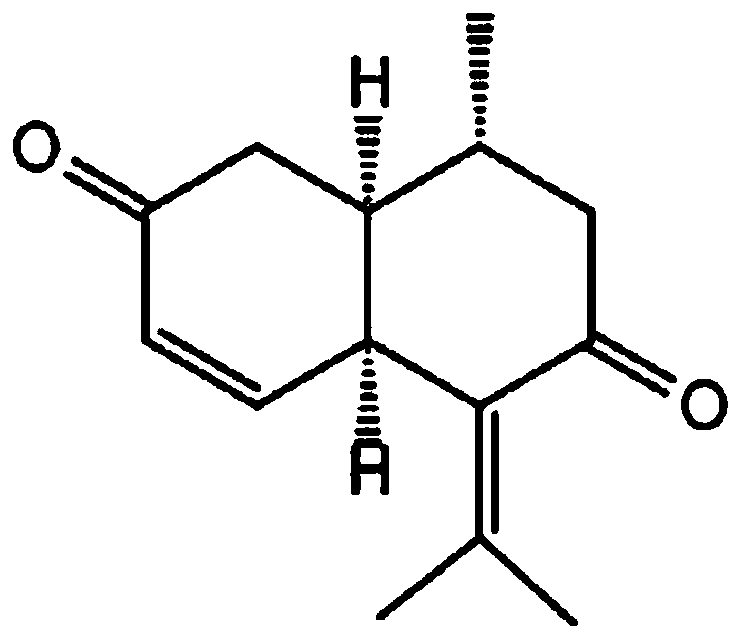

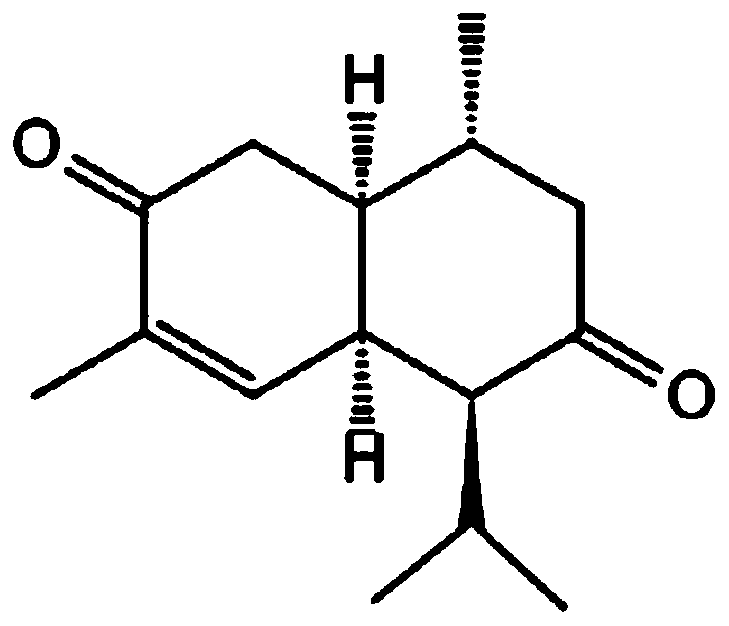

Method for extracting and separating Eupatorium adenophorum ketone compounds from Eupatorium adenophorum

A technology for zelan and zelanone is applied in the field of extracting and separating zelanone compounds, which can solve the problems of complex method and process, low product purity, complex solvent and the like, and achieves reasonable and feasible process, high product purity and transfer rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Medicinal material processing: air-dry in a cool place after collecting Eupatorium adenophorum leaves, and pulverize them to 80-mesh powder with a pulverizer;

[0033] (2) Supercritical CO 2 Extraction: Weigh 1.0Kg of the powder prepared in step (1) and put it in supercritical CO 2 The extraction kettle of the extraction device, the pressure of the extraction kettle is raised to 30MPa, and the temperature is raised to 55°C; the pressure of the analysis kettle I is raised to 18MPa, and the temperature is raised to 50°C; pressure, extraction for 1.0h, after the extraction was completed, the extract from the analysis kettle II was collected to obtain 65.2g of the extract;

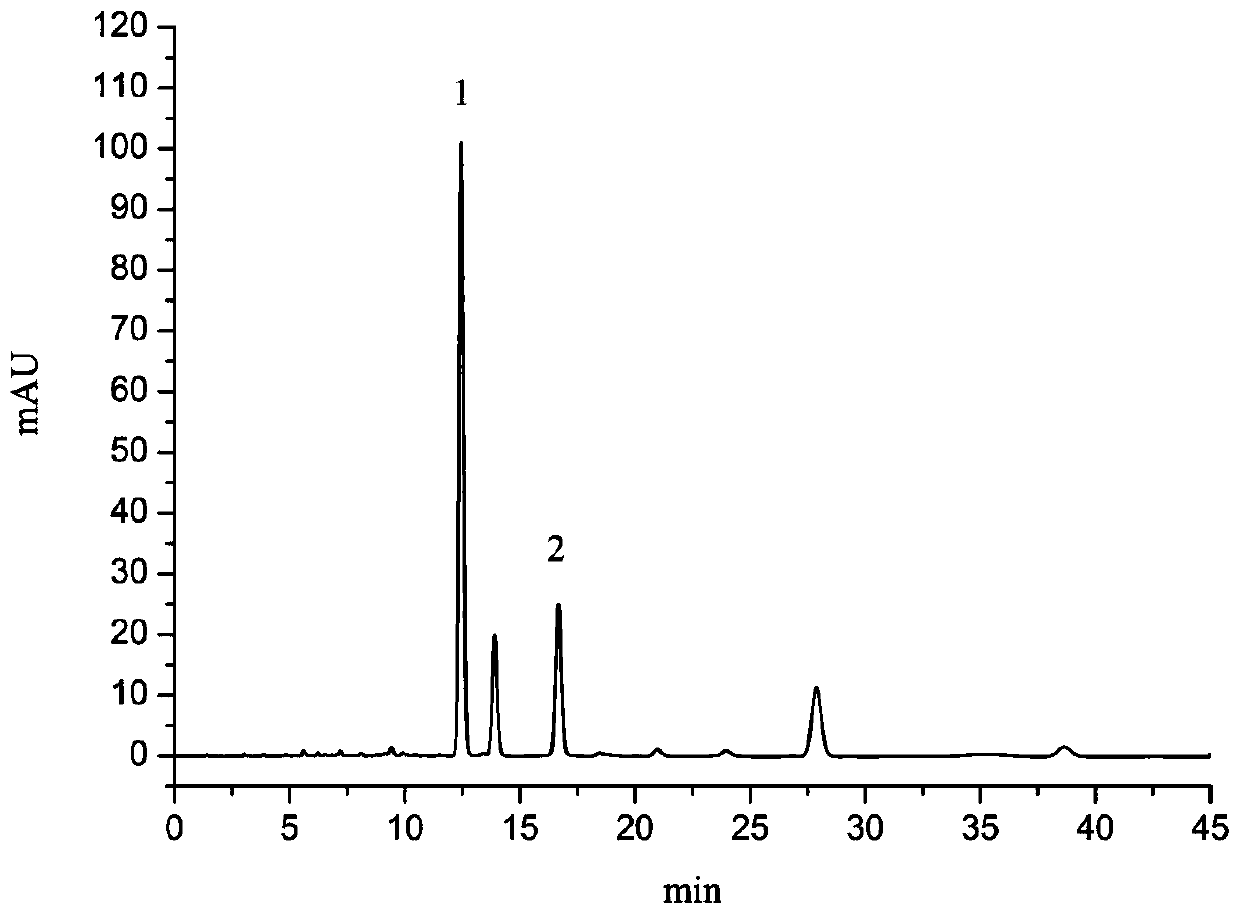

[0034] (3) Molecular distillation separation: Take 60.0 g of the extract obtained in step (2), add it to the constant temperature tank of the molecular distillation device, raise the temperature to 150 ° C, adjust the vacuum to 20 Pa, the speed of the scraping film is 250 r / min, and the condensatio...

Embodiment 2

[0038] (1) Medicinal material processing: air-dry in a cool place after collecting Eupatorium adenophorum leaves, and pulverize them to 60-mesh powder with a pulverizer;

[0039] (2) Supercritical CO 2 Extraction: Weigh 1.0Kg of the powder prepared in step (1) and put it in supercritical CO 2 The extraction kettle of the extraction device, the pressure of the extraction kettle is raised to 35MPa, and the temperature is raised to 45°C; the pressure of the analysis kettle I is raised to 21MPa, and the temperature is raised to 45°C; pressure, extraction for 0.5h, after the extraction was completed, the extract from the analysis kettle II was collected to obtain 65.9g of the extract;

[0040] (3) Molecular distillation separation: Take 60.0 g of the extract obtained in step (2), add it to the constant temperature tank of the molecular distillation device, raise the temperature to 200 ° C, adjust the vacuum to 40 Pa, the speed of the scraping film is 300 r / min, and the condensatio...

Embodiment 3

[0043] (1) Medicinal material processing: Collect the leaves of Eupatorium adenophorum and air-dry them in a cool place, and grind them to 120-mesh powder with a pulverizer.

[0044] (2) Supercritical CO 2 Extraction: Weigh 1.0Kg of the powder prepared in step (1) and put it in supercritical CO 2 The extraction kettle of the extraction device, the pressure of the extraction kettle is raised to 25MPa, and the temperature is raised to 65°C; the pressure of the analysis kettle I is raised to 18MPa, and the temperature is raised to 55°C; pressure, extraction for 1.0h, after the extraction was completed, the extract from the analysis kettle II was collected to obtain 64.7g of the extract;

[0045] (3) Molecular distillation separation: Take 60.0 g of the extract obtained in step (2), add it to the constant temperature tank of the molecular distillation device, raise the temperature to 120 ° C, adjust the vacuum to 10 Pa, the speed of the scraping film is 200 r / min, and the condens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com