Preparation method of titanium dioxide porous spheres

A technology of titanium dioxide and porous balls, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of small specific surface area and low catalytic activity, achieve simple preparation process, improve catalytic activity, and be easy to scale up The effect of batch industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of micron-scale titanium dioxide porous balls, comprising the following steps:

[0030] (1) Add ultrapure water, hydroquinone, and sodium hexametaphosphate successively to the reagent bottle stored in shading, and stir for 30-150 minutes to obtain solution 1;

[0031] (2) adding titanium trichloride into the hydrochloric acid solution, stirring for 10-60 minutes to obtain solution 2;

[0032] (3) Add solution 2 drops to solution 1, stir to obtain solution 3;

[0033] (4) Move solution 3 to a hydrothermal kettle and treat for 12-24 hours;

[0034] (5) After the product is centrifuged, the precipitate is washed and finally dried for 12 hours to obtain the target product. Preferably, the precipitate is washed with water for three times.

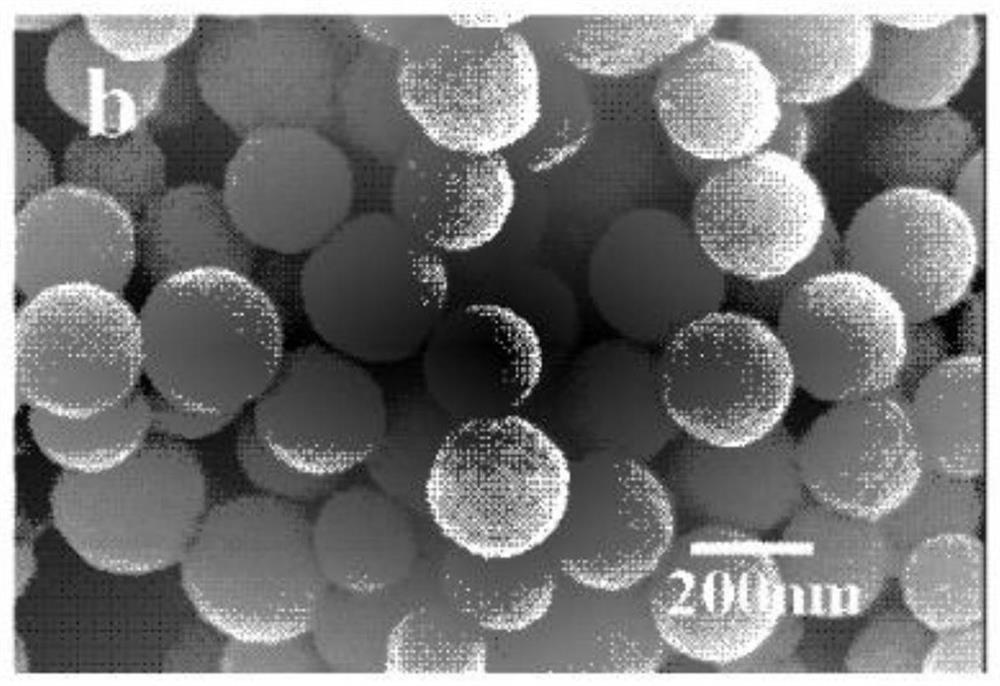

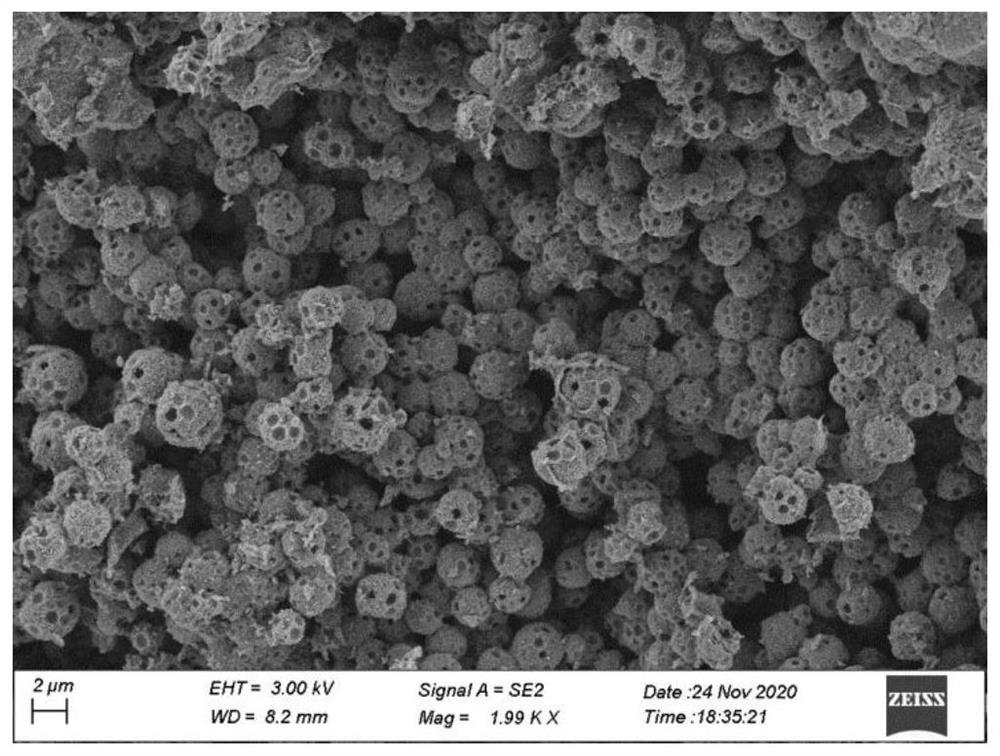

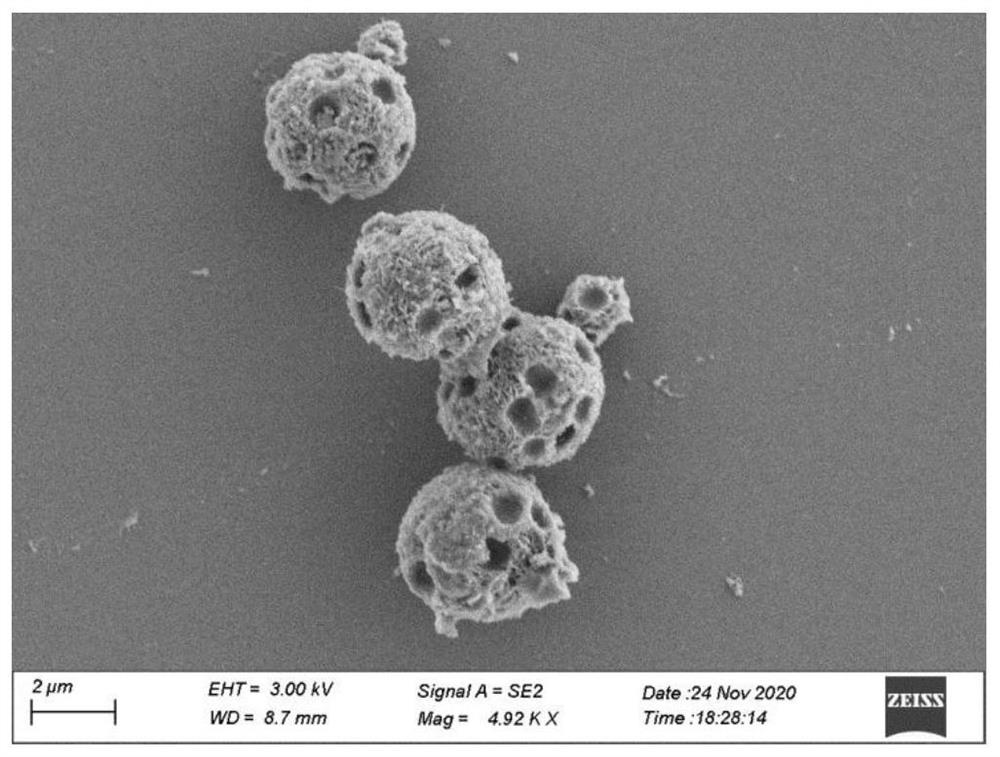

[0035] Through the synergistic effect of the specific organic compound hydroquinone and sodium hexametaphosphate, the process of hydrothermally generating titanium dioxide particles from titanium trichloride is reg...

Embodiment 1

[0046] This embodiment provides a method for preparing micron-sized titanium dioxide porous spheres, comprising the following steps:

[0047] (1) In parts by weight, in a brown bottle coated with tinfoil paper, add 60 parts of ultrapure water, 0.1 part of hydroquinone, and 0.2 parts of sodium hexametaphosphate, and stir for 30-150 minutes to obtain Solution 1.

[0048] (2) Add 15 parts of titanium trichloride to 60 parts of 30% hydrochloric acid solution and stir for 10-60 minutes to obtain solution 2.

[0049] (3) Slowly inject solution 2 dropwise into solution 1 through a syringe pump, and stir for 24-72 hours to obtain solution 3.

[0050] (4) Move solution 3 to a hydrothermal kettle and treat at 160°C for 12-24 hours.

[0051] (5) After the product is centrifuged, washed three times with water, and finally dried at 80° C. for 12 hours, the target product can be obtained.

Embodiment 2

[0053] This embodiment provides a method for preparing micron-sized titanium dioxide porous spheres, comprising the following steps:

[0054] (1) In parts by weight, in a brown bottle coated with tinfoil, add 65 parts of ultrapure water, 3 parts of hydroquinone, and 8 parts of sodium hexametaphosphate, and stir for 30-150 minutes to obtain Solution 1.

[0055] (2) Add 18 parts of titanium trichloride to 70 parts of 30% hydrochloric acid solution and stir for 10-60 minutes to obtain solution 2.

[0056] (3) Slowly inject solution 2 dropwise into solution 1 through a syringe pump, and stir for 24-72 hours to obtain solution 3.

[0057] (4) Move solution 3 to a hydrothermal kettle and treat at 165°C for 12-24 hours.

[0058](5) After the product is centrifuged, washed three times with water, and finally dried at 80° C. for 12 hours, the target product can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com