A spring brush rotation debugging device

A technology of a spring brush and a driving device, applied in the direction of brushes, etc., can solve the problems of waste of resources, the adjustment of the spring brush that cannot be deformed, and the inability to tighten the spring brush, and the effect of easy removal is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

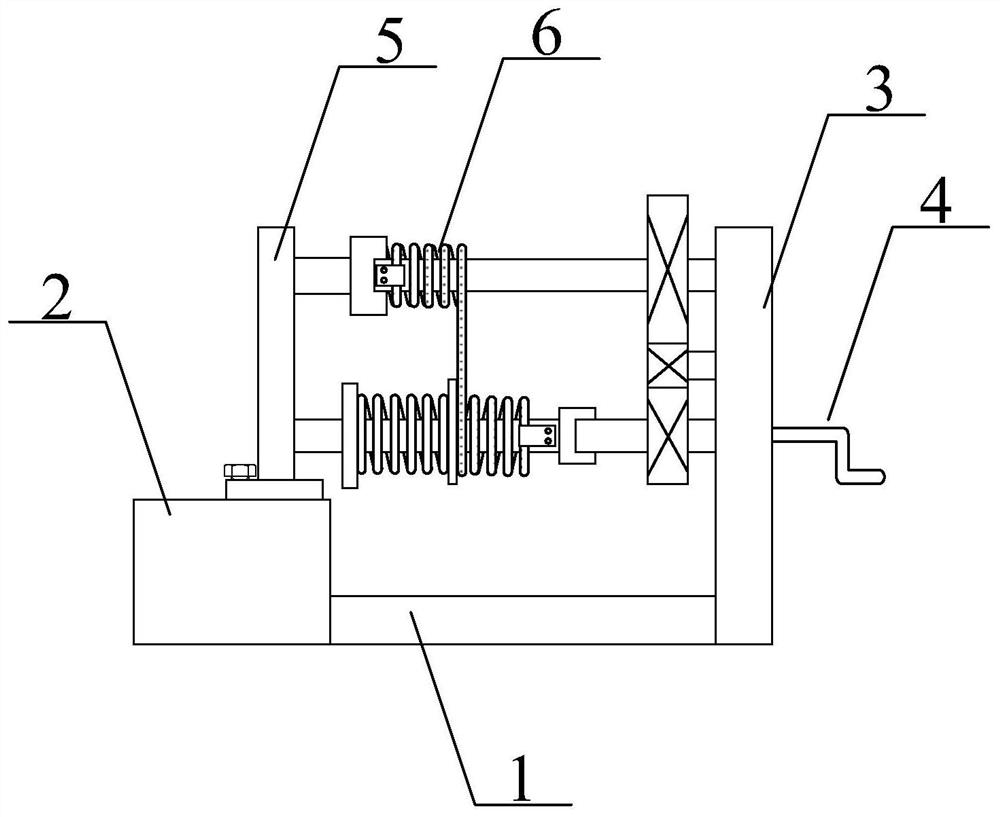

[0022] as attached figure 1 to attach Figure 4 shown

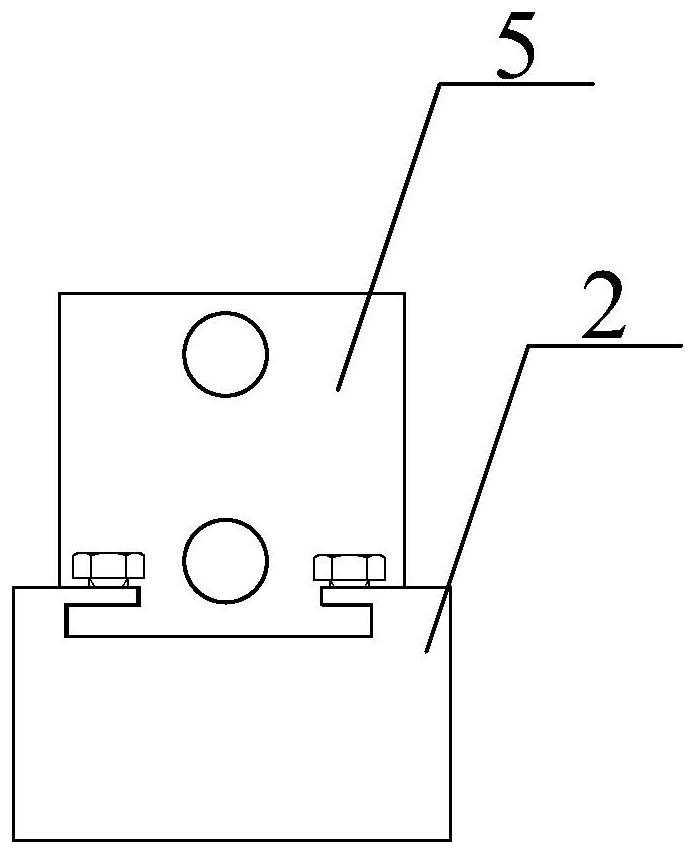

[0023] see figure 1 , a spring brush rotation debugging device, including a base 1, a sliding seat 2, a mounting plate 3, a driving device 4, a sliding tightening mechanism 5 and a spring brush 6, the sliding seat 2 is welded on one side of the base 1; the mounting plate 3 is welded On the other side of the base 1; the driving device 4 is movably connected with the mounting plate 3 through bearings; the sliding tightening mechanism 5 is arranged above the sliding seat 2 and is slidably connected; the spring brush 6 is sleeved on the driving device 4 and passed through the first A pressing plate 47 is fixed.

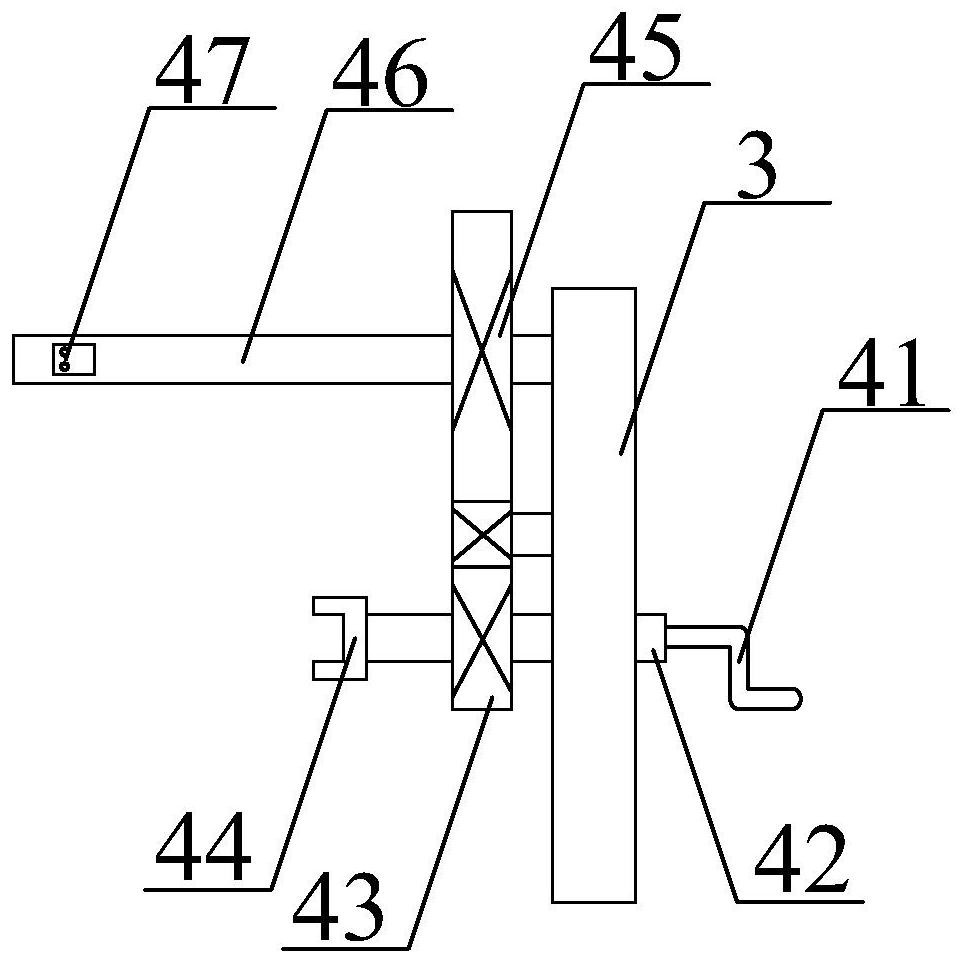

[0024] In the present invention, the driving device 4 includes a crank 41, an input shaft 42, a main gear 43, a first coupling 44, a driven gear 45, an unwinding roller 46 and a first pressure plate 47, and the crank 41 is welded on the input shaft 42. One end of the input shaft 42 runs through the mounting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com