Steel ball bushing for shock absorber of bicycle

A technology of shock absorbers and bicycles, which is applied in the direction of motor vehicles, road vehicles, bearing components, etc., can solve problems such as unsatisfactory use requirements, running positions, unstable directions, etc., to achieve reasonable structure, ensure stability, and enhance safety The effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0024] The technical scheme of concrete implementation of the present invention is:

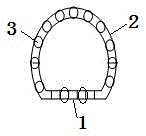

[0025] Such as figure 1 As shown, a bicycle shock absorber has 3 sets of steel balls, including a hollow columnar matrix;

[0026] The base body is open at both axial ends;

[0027] The peripheral wall of the base body is composed of a straight part 1 and an arc part 2 connected end to end along its circumferential direction;

[0028] The straight portion 1 is a plane parallel to the axis of the substrate;

[0029] The arc portion 2 is a part of a cylindrical surface coaxial with the base;

[0030] Along the circumferential direction of the peripheral wall of the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com