Large-sized volume-varied movable thermal treatment furnace

A heat treatment furnace and mobile technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of inapplicable heat treatment of large components, lifting equipment, lifting height and lifting radius limitations, immature technology, etc., to achieve improved The effects of repeated utilization, reduced lifting height, and simple disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

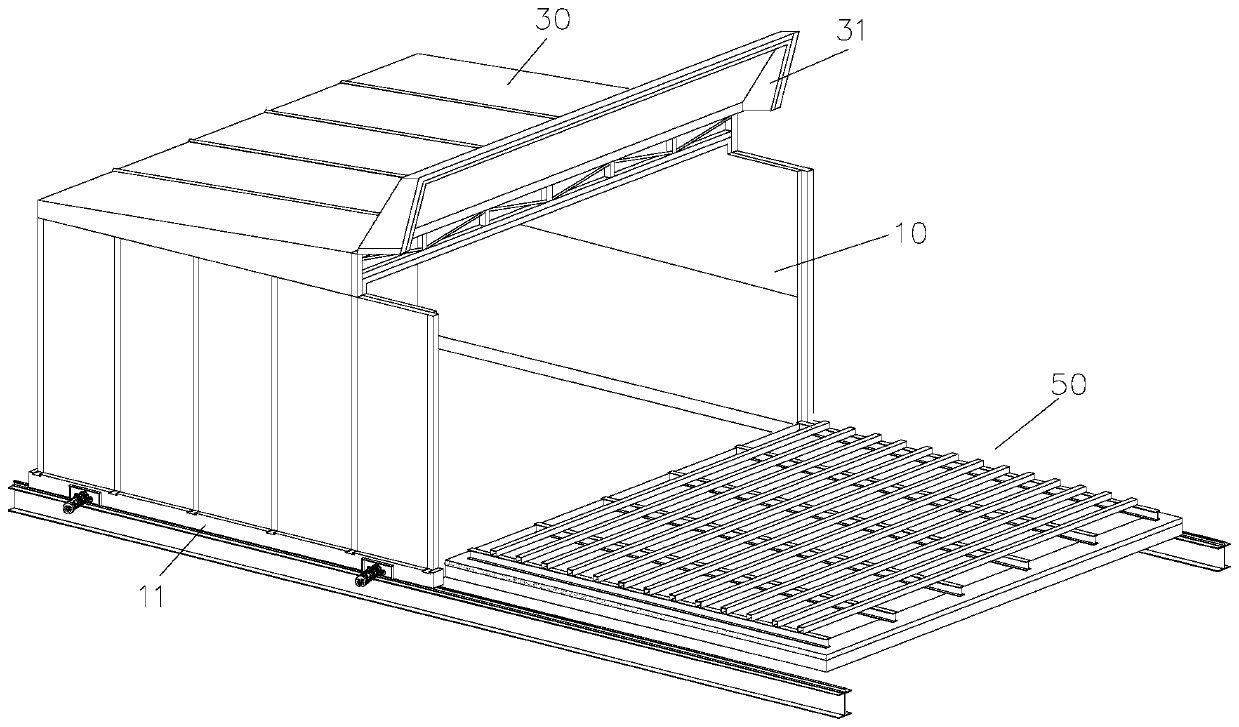

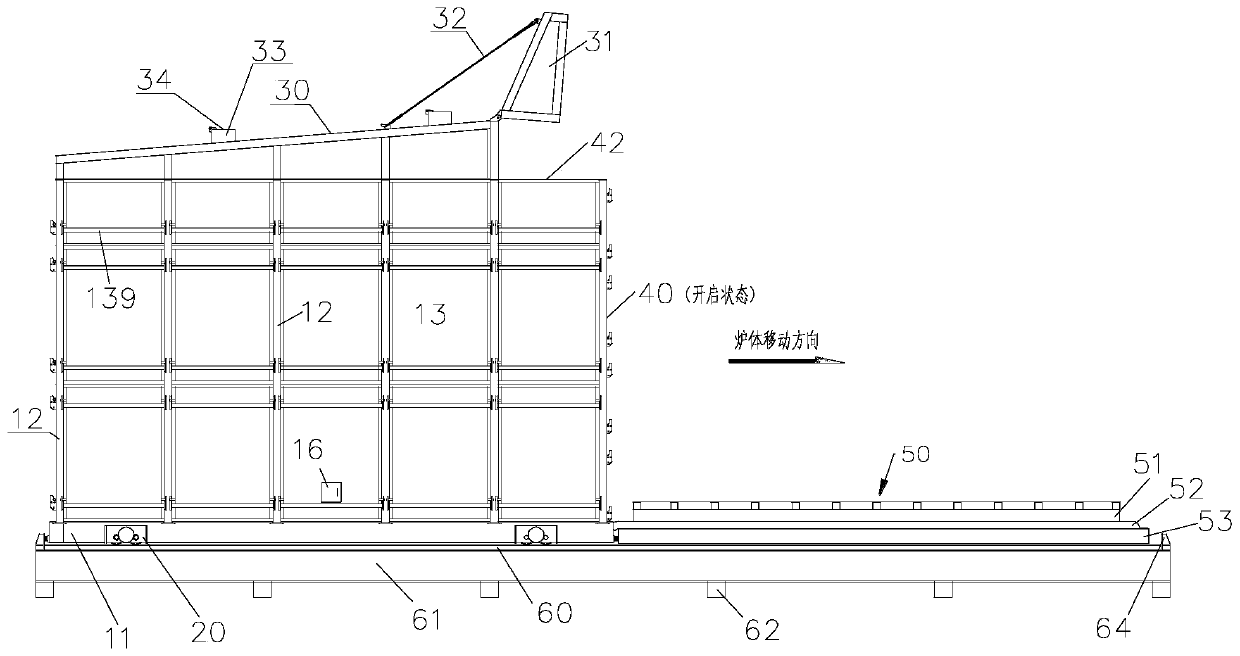

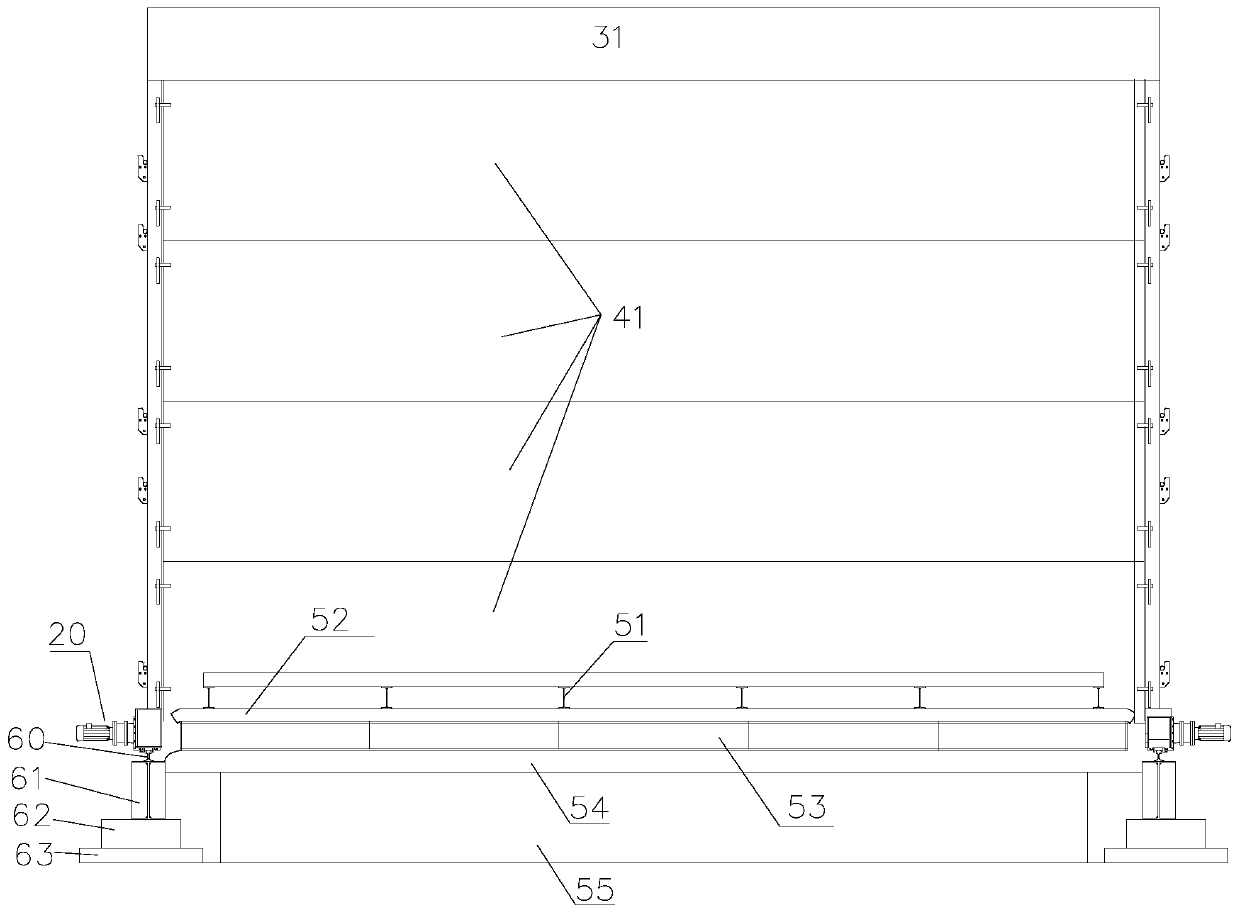

[0033] Such as Figure 1-3 As shown, it is a variable-capacity movable large-scale heat treatment furnace according to a preferred embodiment of the present invention, including furnace wall panels 10 located on the left, right and rear sides and a furnace roof cover installed above the furnace wall panels 10 on three sides 30. The furnace wall panels 10 on the left and right sides are symmetrically arranged, and the furnace wall panels 10 on three sides and the furnace roof cover 30 together constitute the furnace body of the heat treatment furnace. The furnace wall panel 10 is assembled from several furnace wall panel modules through detachable connections, and the number of furnace wall panel modules can be adjusted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com