Civil engineering air duct lining air pipe structure and construction method thereof

A technology of civil air ducts and concrete structures, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of air duct tearing, increasing the area occupied by air ducts, and difficult installation, so as to enhance the connection strength and reduce the Difficulty of installation and the effect of reducing the floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

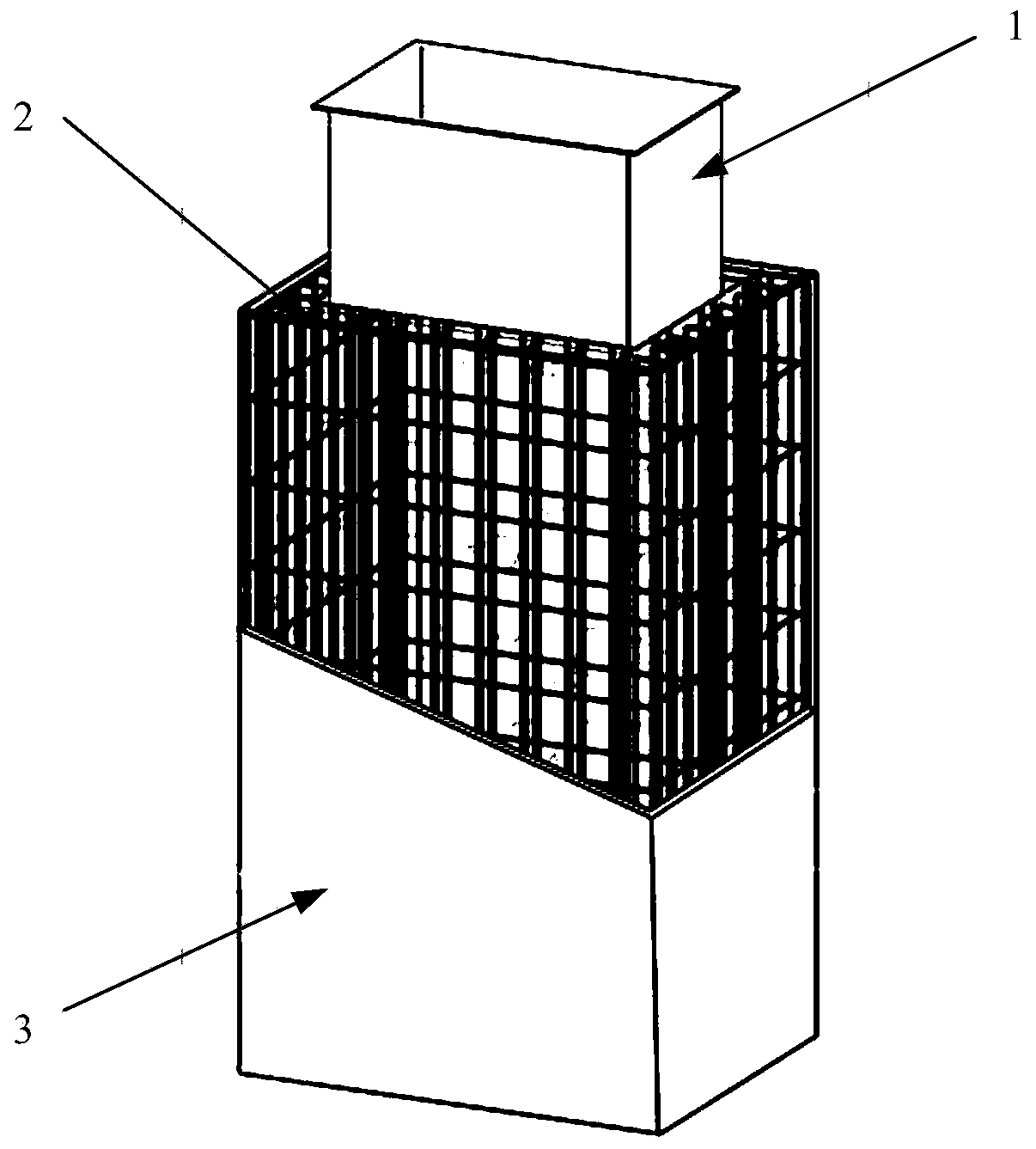

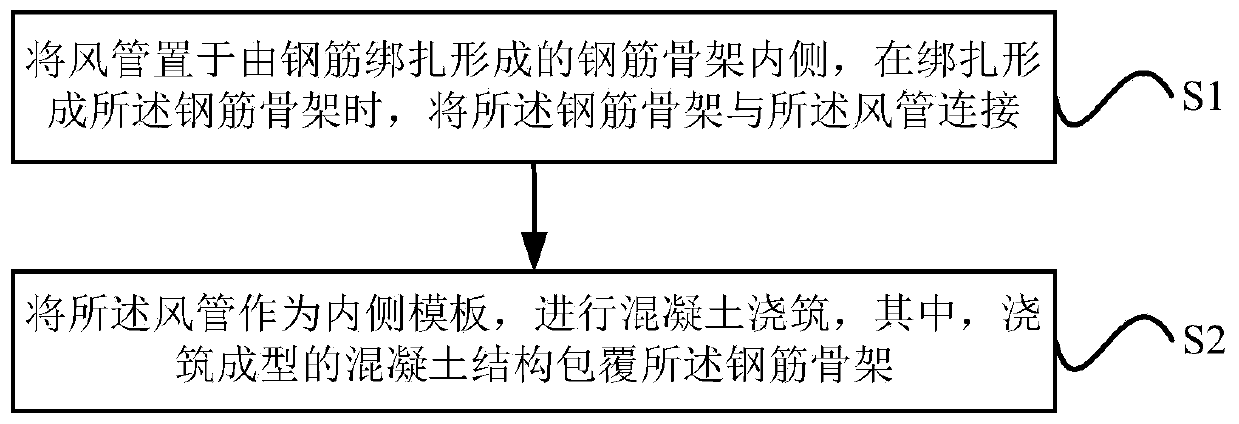

[0013] Such as figure 1 As shown, the civil air duct lining air duct structure provided by the embodiment of the present invention includes at least one section of air duct 1, a steel skeleton 2 and concrete; the steel skeleton 2 is arranged outside the air duct 1 and connected to the air duct 1; concrete pouring On the outside of the air duct 1 , the inner wall of the poured concrete structure 3 abuts against the outer wall of the air duct 1 , and the poured concrete structure 3 covers the steel skeleton 2 .

[0014] In this embodiment, the air duct 1 is used as the inner formwork for pouring the concrete air duct. Before pouring, the air duct 1 and the steel frame 2 can be bound and welded to enhance the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com