A high-efficiency heat-conducting oil boiler

A technology of heat transfer oil boiler and heat transfer oil, which is applied in heat storage heaters, fluid heaters, lighting and heating equipment, etc., and can solve problems such as reducing the utilization rate of heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

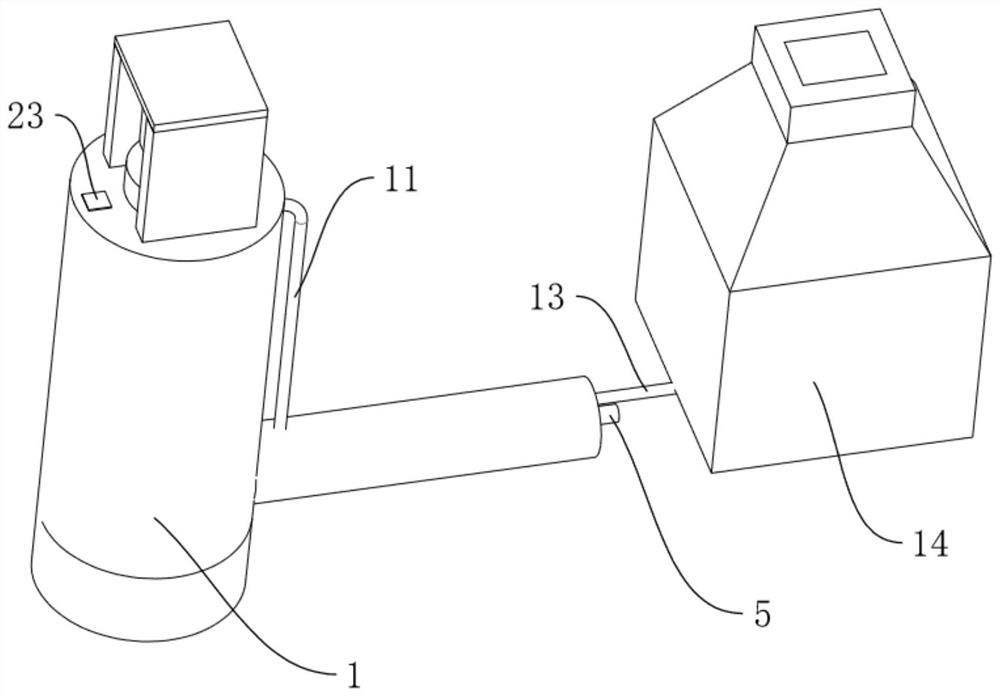

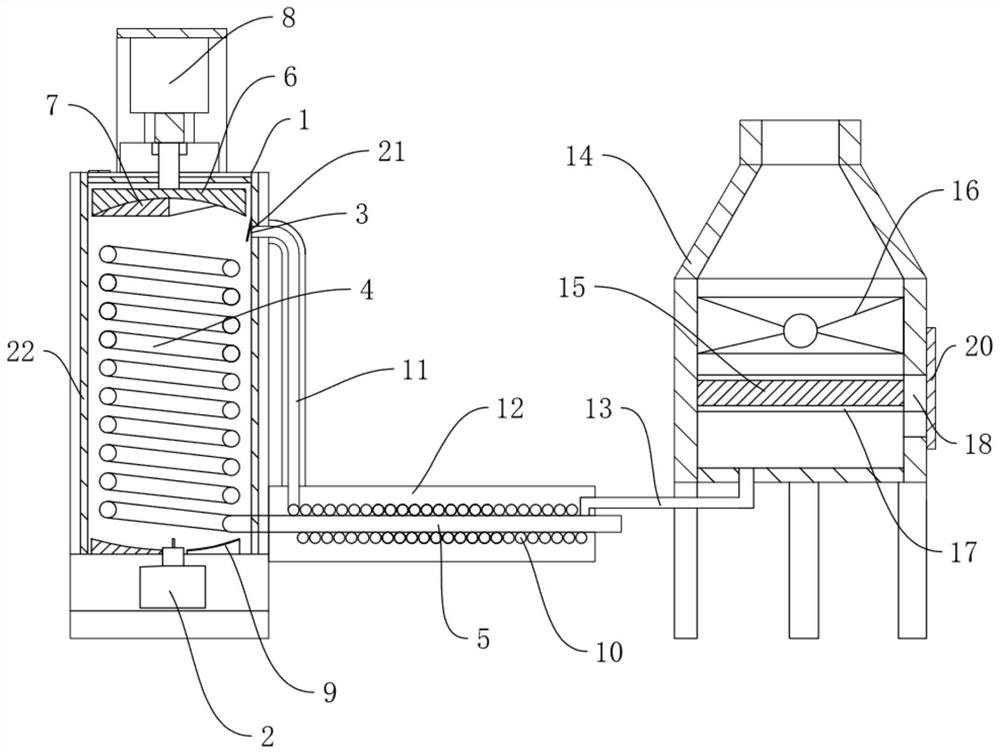

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with illustrations and specific embodiments.

[0022] Such as figure 1 and figure 2 As shown, a high-efficiency heat-conducting oil boiler proposed by the present invention includes a heat-conducting oil boiler body 1, a burner 2 for heating heat-conducting oil is installed on the lower end of the heat-conducting oil boiler body 1, and the side wall of the heat-conducting oil boiler body 1 is close to the upper surface. The end face position is provided with exhaust gas outlet 3 for the exhaust gas after combustion. The heat transfer coil 4 for the flow of heat transfer oil is installed in the heat transfer oil boiler body 1. There is a certain gap between the heat transfer coil 4 and the inner wall of the heat transfer oil boiler body 1. The heat conduction coil 4 is conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap