Transformer pin leveling machine

A leveling machine and transformer technology, applied in the field of transformers, can solve the problems of low qualified rate of finished products, easy deformation, low pin thickness, etc., achieve the effect of strengthening connection, avoiding shaking, and improving product qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

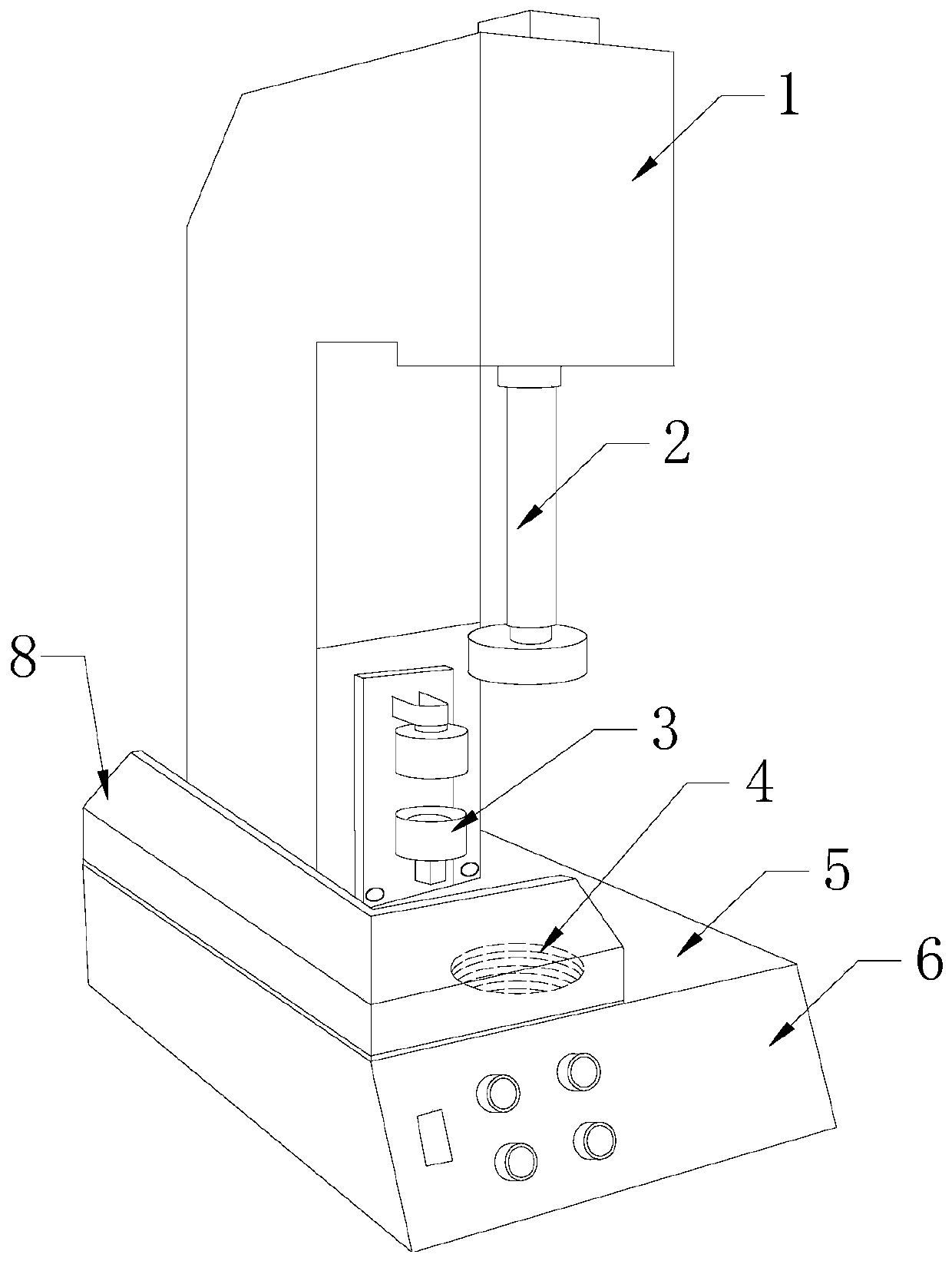

[0025] see Figure 1-Figure 4 , the present invention provides a transformer pin leveling machine, the structure of which includes a hydraulic press 1, a cover mold 2, a fixing ring 3, a mounting hole 4, a machine table 5, a control panel 6, and a bottom mold 7. The top surface of the machine table 5 There is a mounting hole 4 in the middle, and a bottom mold 7 is installed in the mounting hole 4, the bottom mold 7 is facing the cover mold 2, the cover mold 2 and the bottom mold 7 are movably matched, and the cover mold 2 It is mechanically connected with the hydraulic machine 1, the front end of the machine table 5 is embedded with a control panel 6, the control panel 6 is electrically connected with the hydraulic machine 1, and a fixing ring 3 is installed directly below the hydraulic machine 1. The hydraulic press 1 is provided with two matching holes.

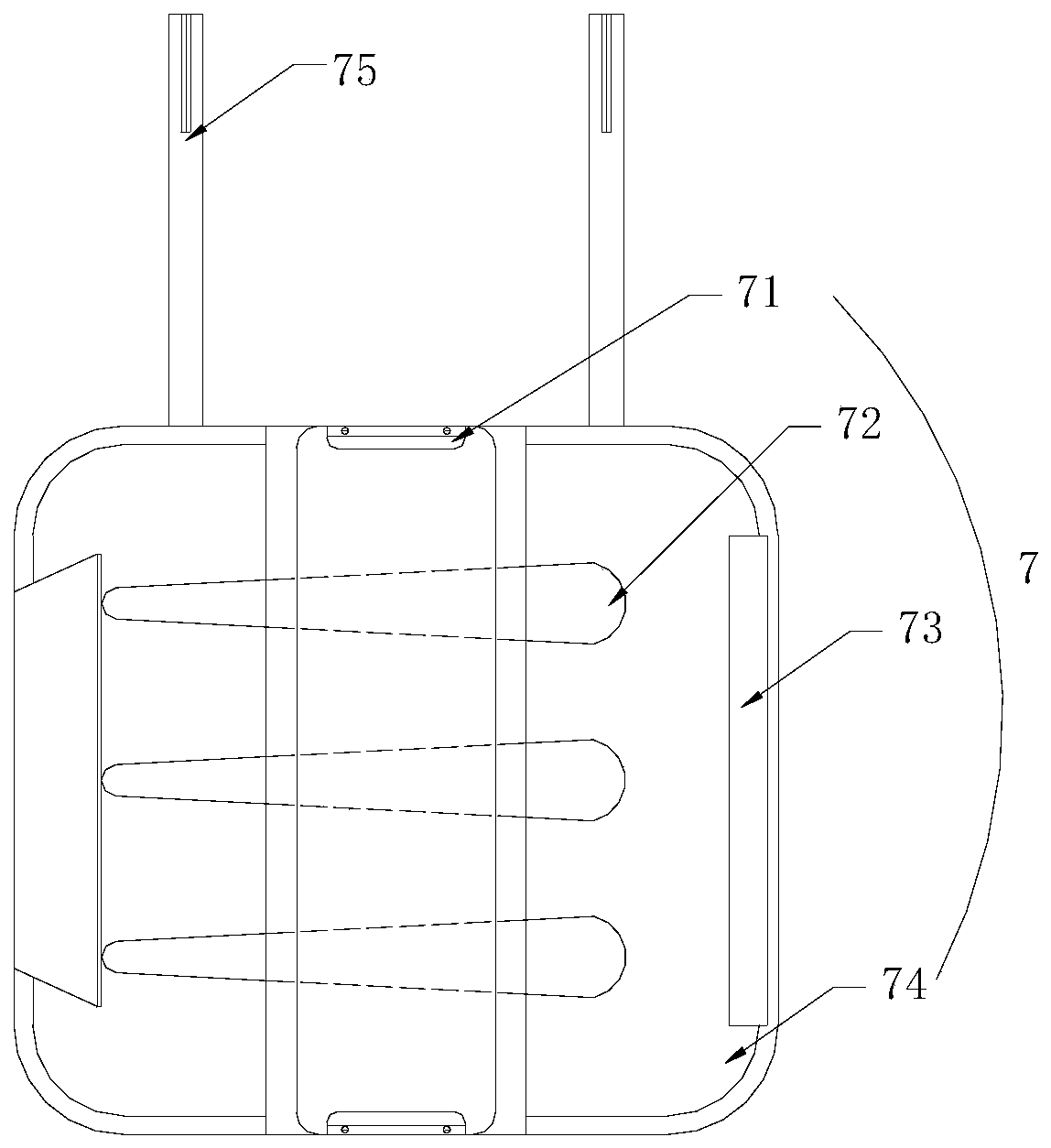

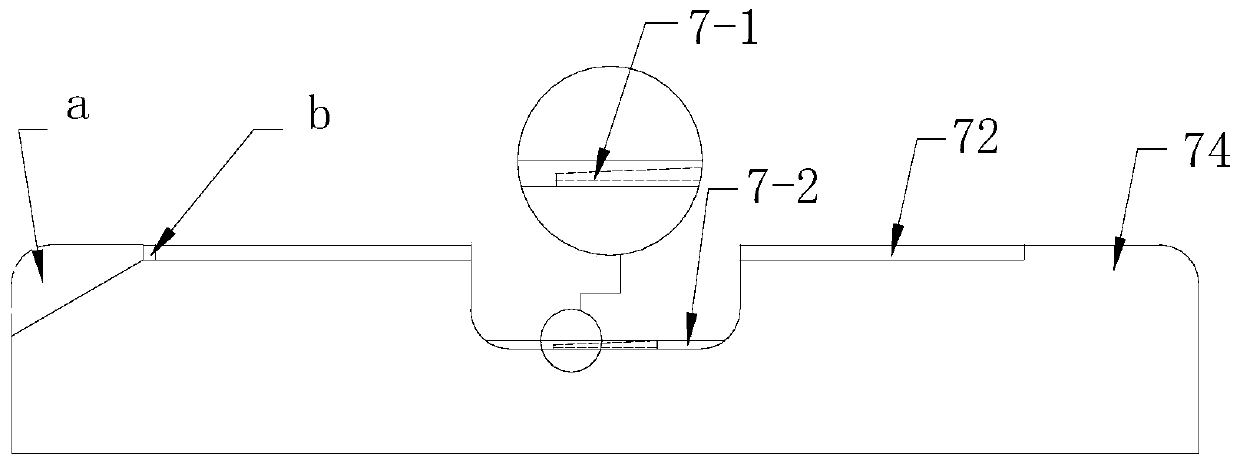

[0026] The bottom mold 7 is composed of an automatic pop-up structure 71, an insert groove 72, a insert strip 73, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com