A high-precision composite material antenna reflective surface forming method

A kind of composite material, molding method technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

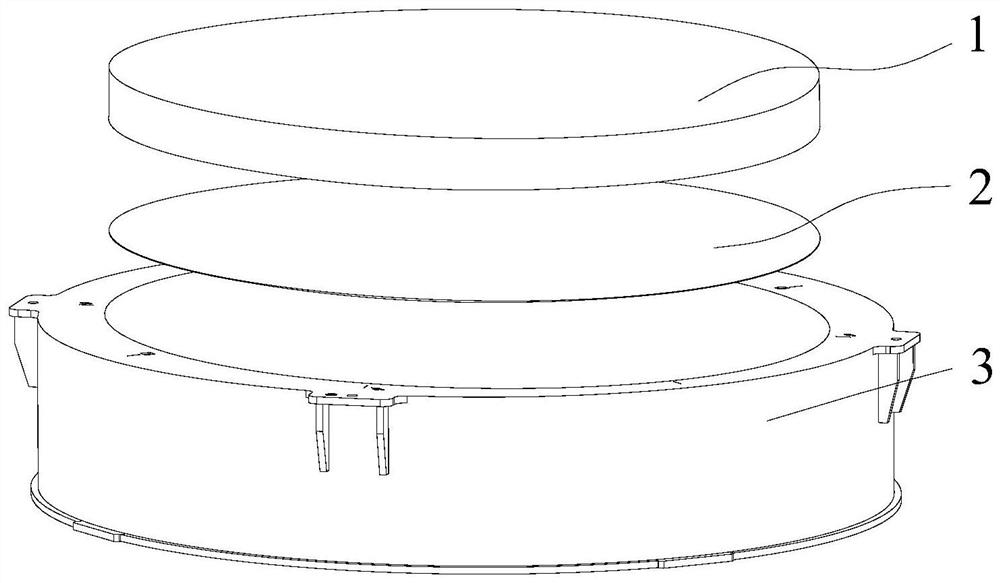

Image

Examples

Embodiment 1

[0035] This embodiment provides a method for forming a high-precision composite antenna reflective surface, specifically as follows:

[0036] S1. Sand the surface of the reflective surface evenly with sandpaper until there is no smooth area on the surface;

[0037] S2. Clean the surface of the reflective surface forming mold and apply a release agent for subsequent use;

[0038] S3. Pour the prepared epoxy resin on the mold. The curing temperature of the epoxy resin is 35°C. At this time, the viscosity of the resin is 1300mPa·s, and the time for maintaining this viscosity is 10h. Fix the reflective surface on the mold. On the actuator operated by the reflective surface, and placed together in the vacuum environment box;

[0039] S4. Vacuumize the vacuum environment box until the absolute vacuum degree in the box is 2Pa, the temperature is 20°C, and keep in this state for 5h;

[0040] S5. Use the actuator to press the reflective surface on the mold with resin, so that the res...

Embodiment 2

[0044] This embodiment provides a method for forming a high-precision composite antenna reflective surface, specifically as follows:

[0045] S1. Sand the surface of the reflective surface evenly with sandpaper until there is no smooth area on the surface;

[0046] S2. Clean the surface of the reflective surface forming mold and apply a release agent for subsequent use;

[0047] S3. Pour the prepared epoxy resin on the mold. The curing temperature of the epoxy resin is 45°C. At this time, the viscosity of the resin is 300mPa·s, and the time for maintaining this viscosity is 12h. Fix the reflective surface on the mold. On the actuator operated by the reflective surface, and placed together in the vacuum environment box;

[0048] S4. Vacuumize the vacuum environment box until the absolute vacuum degree in the box is 4Pa, the temperature is 20°C, and keep in this state for 4h;

[0049] S5. Use the actuator to press the reflective surface on the mold with resin, so that the resi...

Embodiment 3

[0053] This embodiment provides a method for forming a high-precision composite antenna reflective surface, specifically as follows:

[0054] S1. Sand the surface of the reflective surface evenly with sandpaper until there is no smooth area on the surface;

[0055] S2. Clean the surface of the reflective surface forming mold and apply a release agent for subsequent use;

[0056] S3. Pour the prepared epoxy resin on the mold. The curing temperature of the epoxy resin is 20°C. At this time, the viscosity of the resin is 2000mPa·s, and the time for maintaining this viscosity is 7h. Fix the reflective surface on the mold. On the actuator operated by the reflective surface, and placed together in the vacuum environment box;

[0057] S4. Vacuumize the vacuum environment box until the absolute vacuum in the box is 3×10 -4 Pa, the temperature is 20°C, and keep in this state for 6h;

[0058] S5. Use the actuator to press the reflective surface on the mold with resin, so that the res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com