Liquid silicagel preparation and injection moulding method

An injection molding, liquid silicone technology, applied in the direction of coating, can solve the problems of material bubbles, affecting the service life and aesthetics, unable to fully solidify, etc., to reduce errors, reduce uneven preparation, improve manufacturing speed and model quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Due to the long overall size, this design needs to be poured twice;

[0057] (2) Raw material preparation: first weigh 15.0 g of silica gel A reagent with an electronic balance;

[0058] (3) Reagent mixing: After clearing the balance, continue to add 15.0 g of B reagent, and the whole operation process is about 3 minutes;

[0059] (4) Stirring vulcanization: the operating room temperature is 24°C, the stirring speed is about 70rmp, and the stirring time is controlled for 90s to fully mix the materials;

[0060] (5) Remove air bubbles: pour the raw materials prepared in step (3) into a centrifuge tube, and remove air bubbles by centrifuging for 1 min with a centrifuge speed of 3000rmp;

[0061] (6) Mold treatment: apply a layer of glycerin evenly in the mold with a brush;

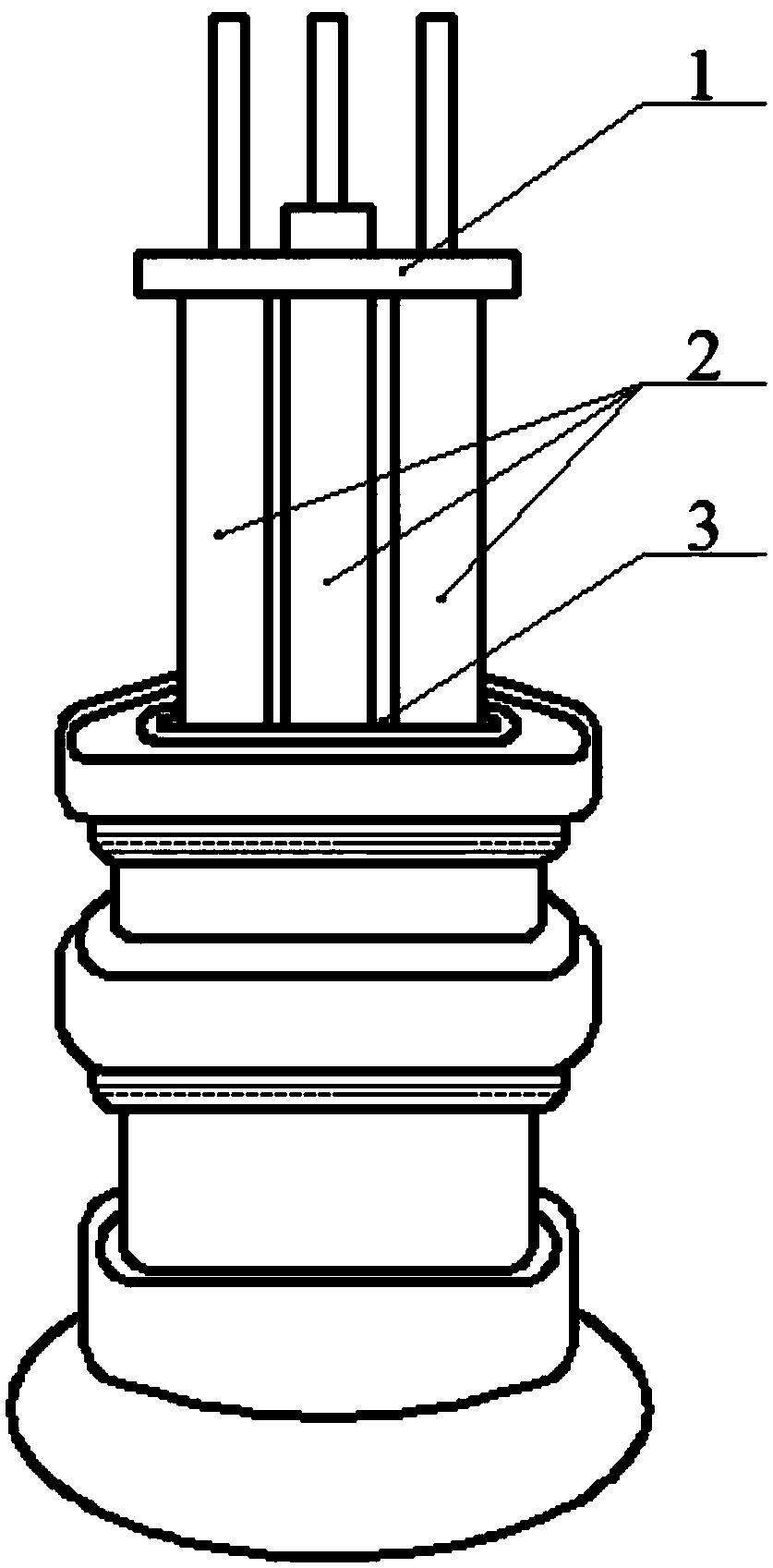

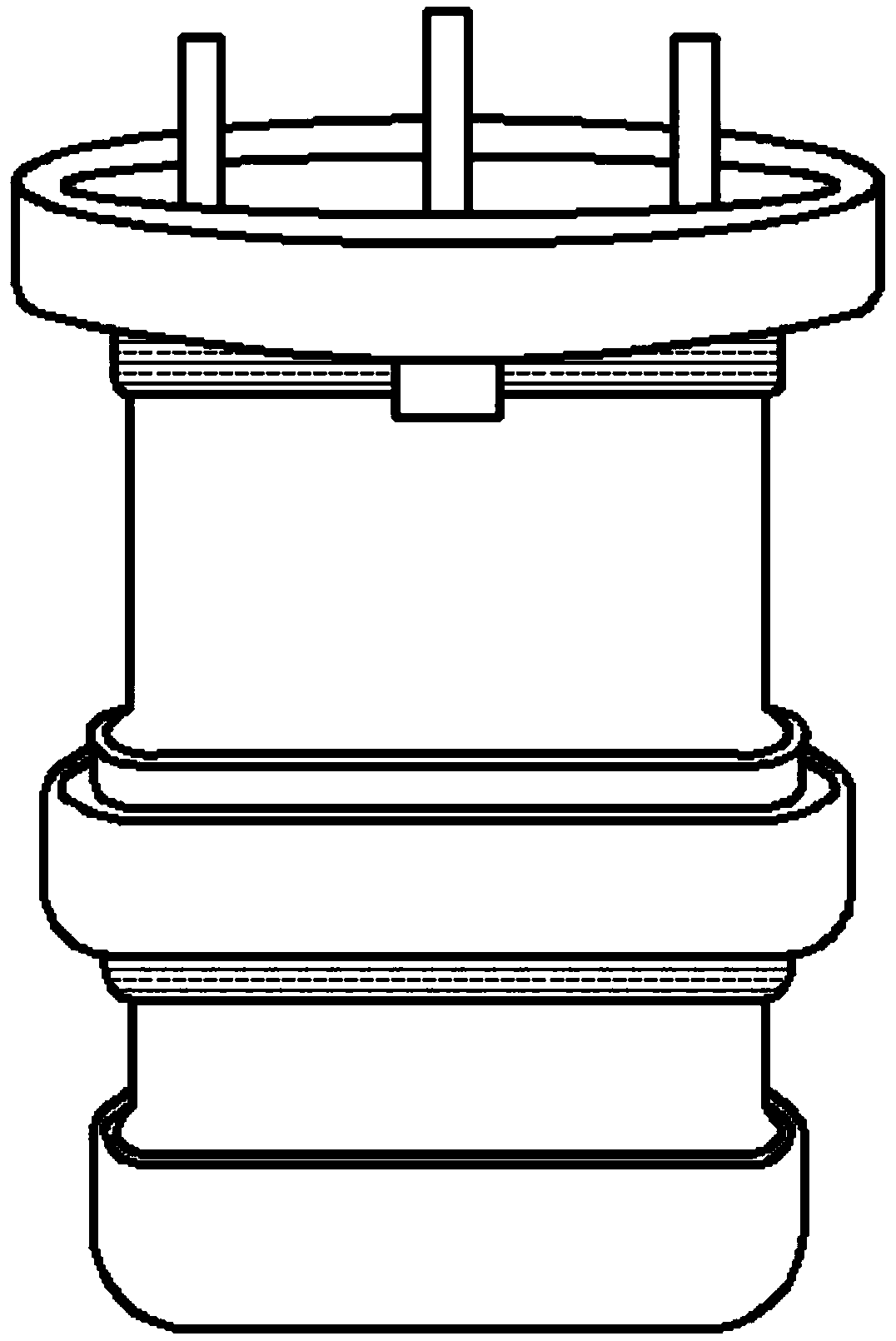

[0062] (7) Injection molding: Slowly inject the mixed raw materials without bubbles after centrifugation in step (4) into the inner cavity of the first molding mold 3 ( figure 1 ) to fill the e...

Embodiment 2

[0069] (1) Raw material preparation: It is estimated that the finished product needs about 28g of silica gel. Considering the possible waste in the material configuration process, the best ratio of silica gel curing is 1:1, so pour the silica gel A reagent into the beaker during the material ratio stage 15.0g;

[0070] (2) Reagent mixing: After clearing the balance, continue to add 15.0 g of reagent B, and the whole operation process is about 3 minutes;

[0071] (3) Stirring vulcanization: operate at room temperature of 28°C, use a magnetic stirrer to stir at a speed of about 40rmp, and stir for 5 minutes to fully mix reagent A and reagent B;

[0072] (4) Remove air bubbles: pour the raw materials prepared in step (3) into a centrifuge tube, and remove air bubbles with a centrifuge for 2 minutes, and the centrifugal speed is 2500rmp;

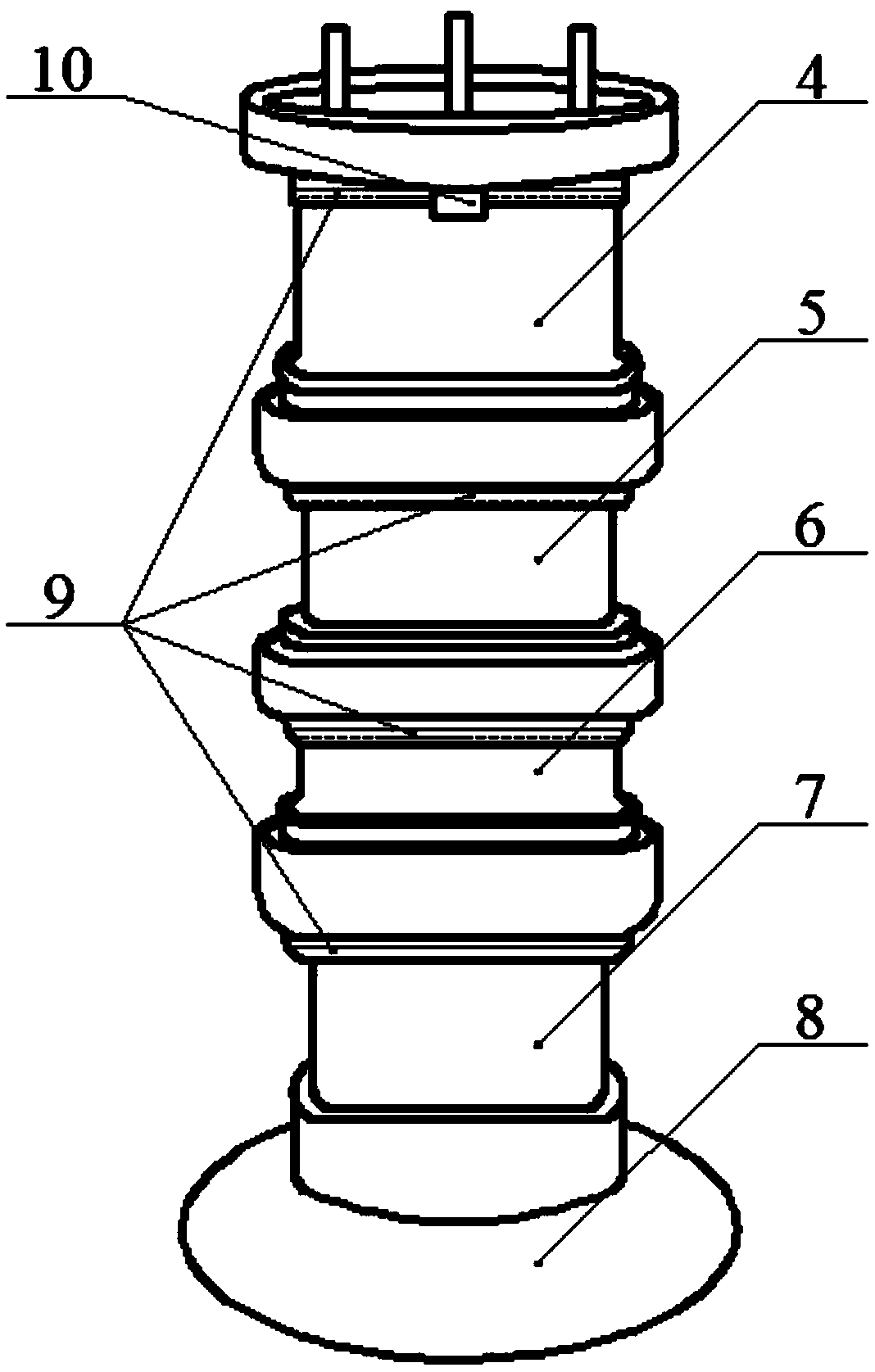

[0073] (5) Mold treatment: use a brush on the inner side of the outer wall 13 of the mold ( Figure 4 ) apply a layer of glycerin evenly;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com