Retaining system for joints

A technology for maintaining systems and connecting components, applied in applications, rod connections, household appliances, etc., can solve problems such as expensive, inefficient, and difficult to make connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

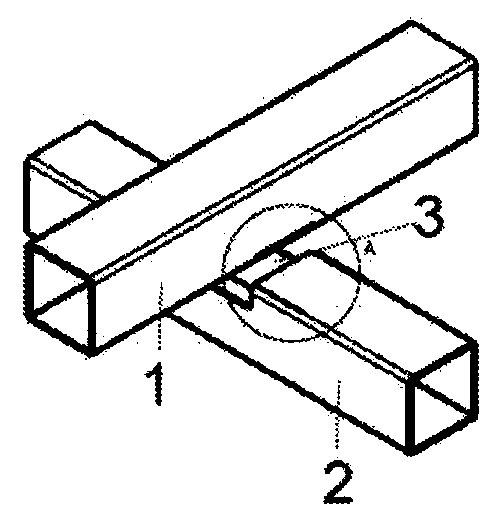

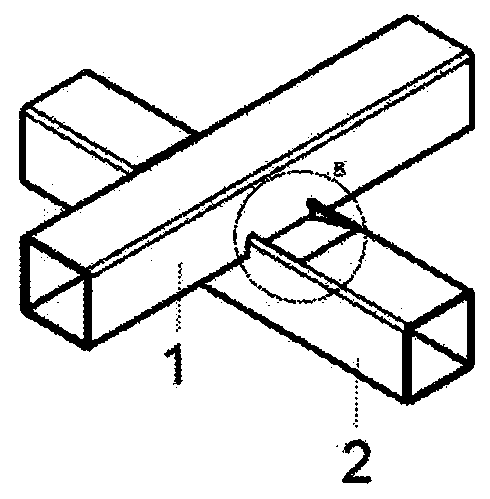

[0082] By means of a preferred embodiment of the "holding system for coupling" according to Figure 1 to Figure 17 It can be seen how the invention solves the joining of two square tubular profiles 1 , 2 made of carbon steel.

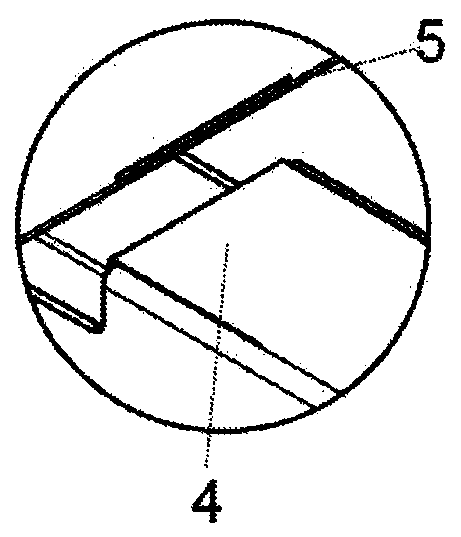

[0083] Thus, for example, it is possible to make cuts on both profiles using laser technology, so that two slots 5 are made on the top profile 1, the corresponding insertion gap 3 and the four cuts that will produce two tabs must then be made on the bottom profile 2, wherein the latter is produced on the top surface of said bottom profile 2 and adjacent to the embedding gap.

[0084] To carry out the described joining of the profiles, it is sufficient to insert the top profile 1 manually and vertically inside the bottom profile 2 through the insertion gap 3 of the bottom profile 2, wherein the two tongues 4 are locked as the two profiles approach each other. Forced to bend, and until the two fit together at the end of their travel, at which point tab 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com