Inner spinning feeding device for bottom plate of opposite-wheel driving power spinning equipment

A technology of powerful spinning and equipment bottom plate, which is applied in the direction of gear transmission, transmission, mechanical equipment, etc., can solve the problems of poor versatility, long manufacturing cycle, high cost of core mold, etc., achieve high positioning accuracy, improve the state of stress, The effect of small mechanism size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

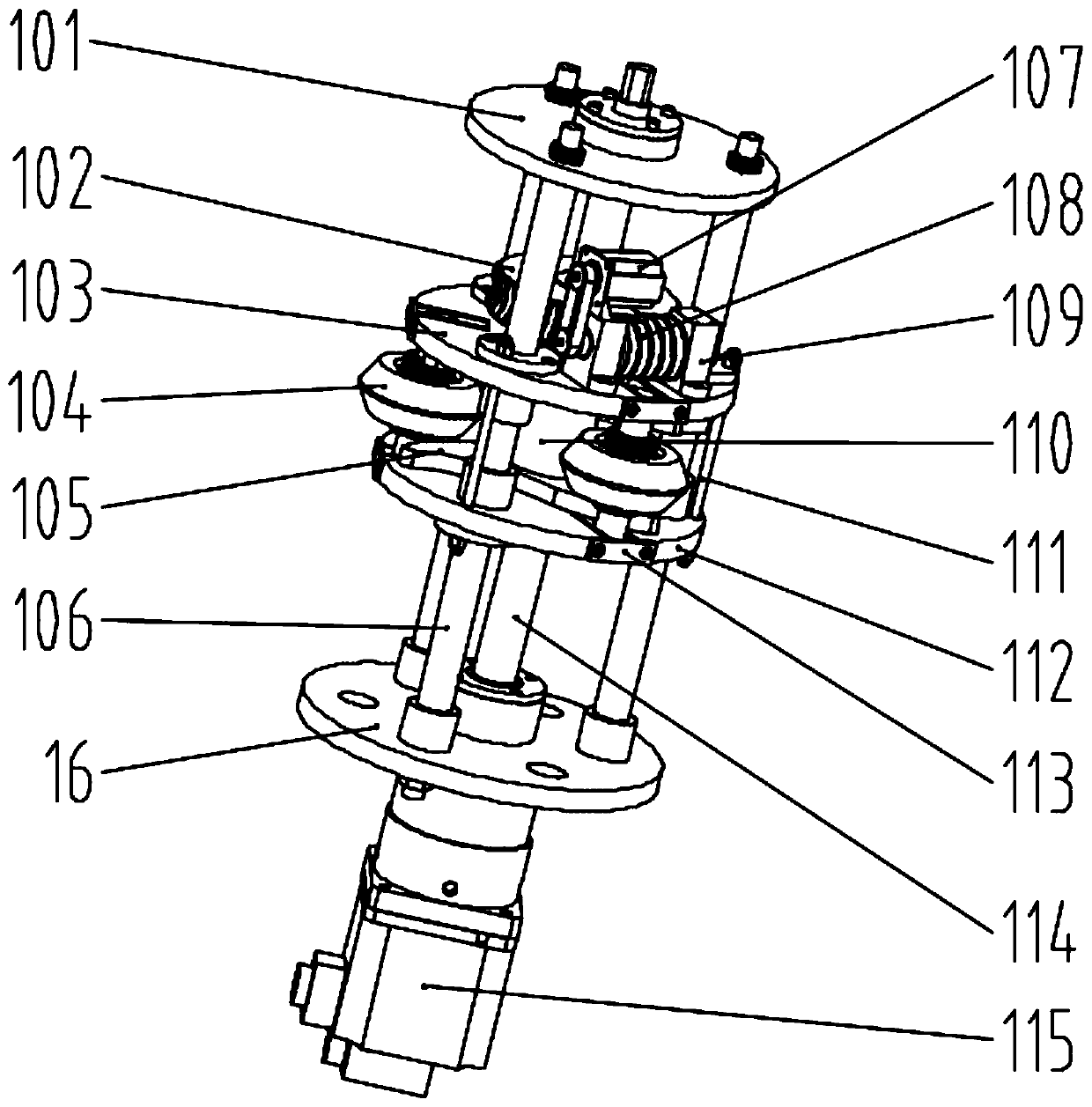

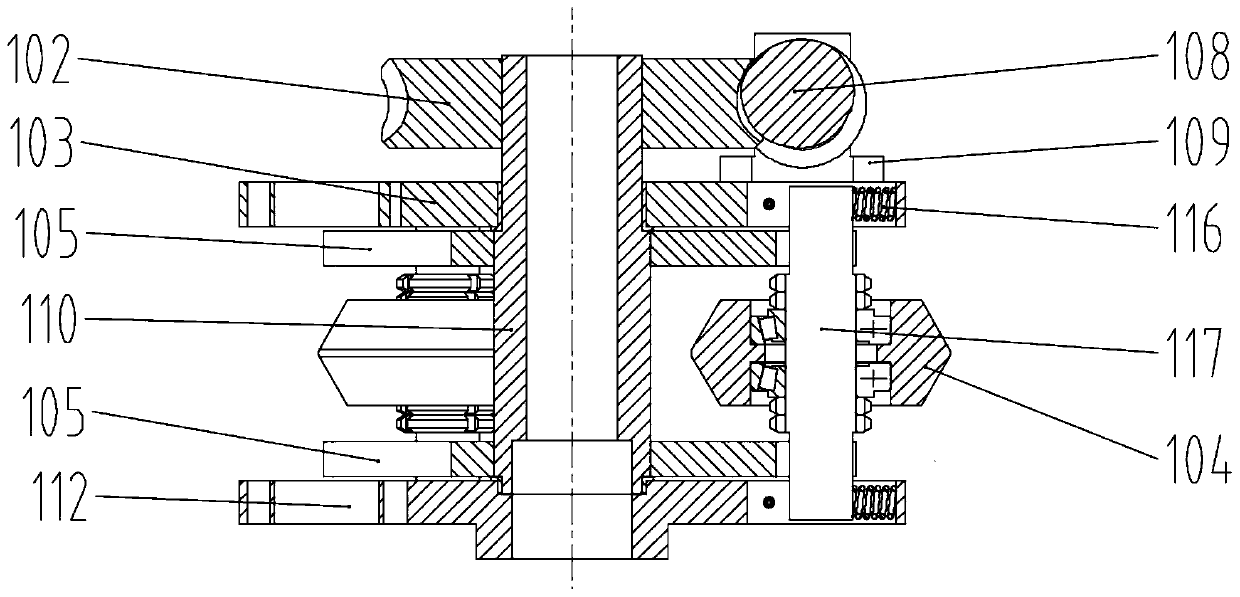

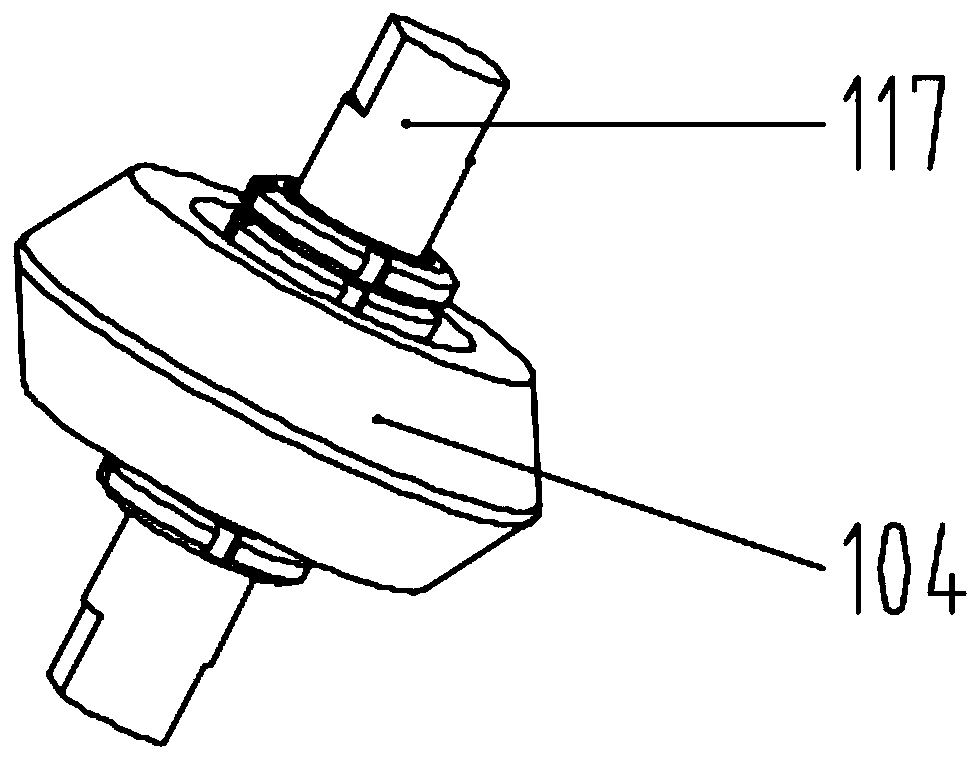

[0037] Implementation method: when the inner wheel 104 is fed radially along the workpiece, the brake motor 107 is used as the power source to drive the worm 108 to rotate through the synchronous pulley, and the worm 108 rotates so that the worm wheel 102 drives the cam installation cylinder 110 to rotate, and the cam installation cylinder 110 The drive cam 105 rotates around the axis, and the convex surface of the cam 105 is tangent to the inner roller shaft 117 so that the inner roller shaft 117 moves outward along the U-shaped grooves on the upper plate 103 of the inner roller and the lower plate 112 of the inner roller to realize radial feed . At the same time, the self-locking function of the worm gear and the brake motor are used to ensure that the inner wheel can be accurately positioned for processing after being radially fed to the specified position.

[0038] During the return journey of the inner turning wheel 104, the reverse rotation of the brake motor 107 first d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com