Black rice and spring automatic assembling device

An automatic assembly and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of operator fatigue, inability to ensure each component, and lower product quality, so as to ensure assembly efficiency and quality, Ease of operation and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

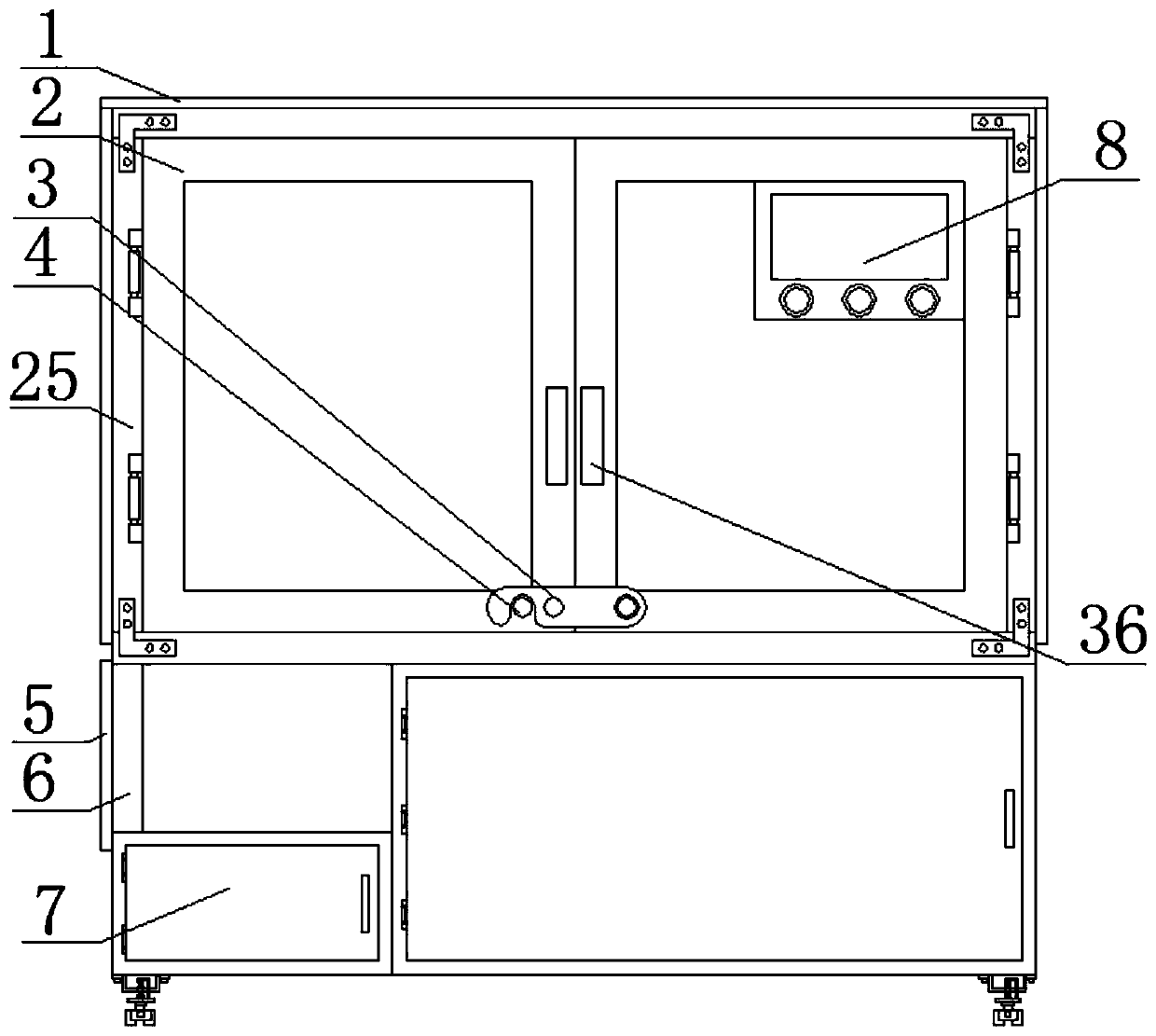

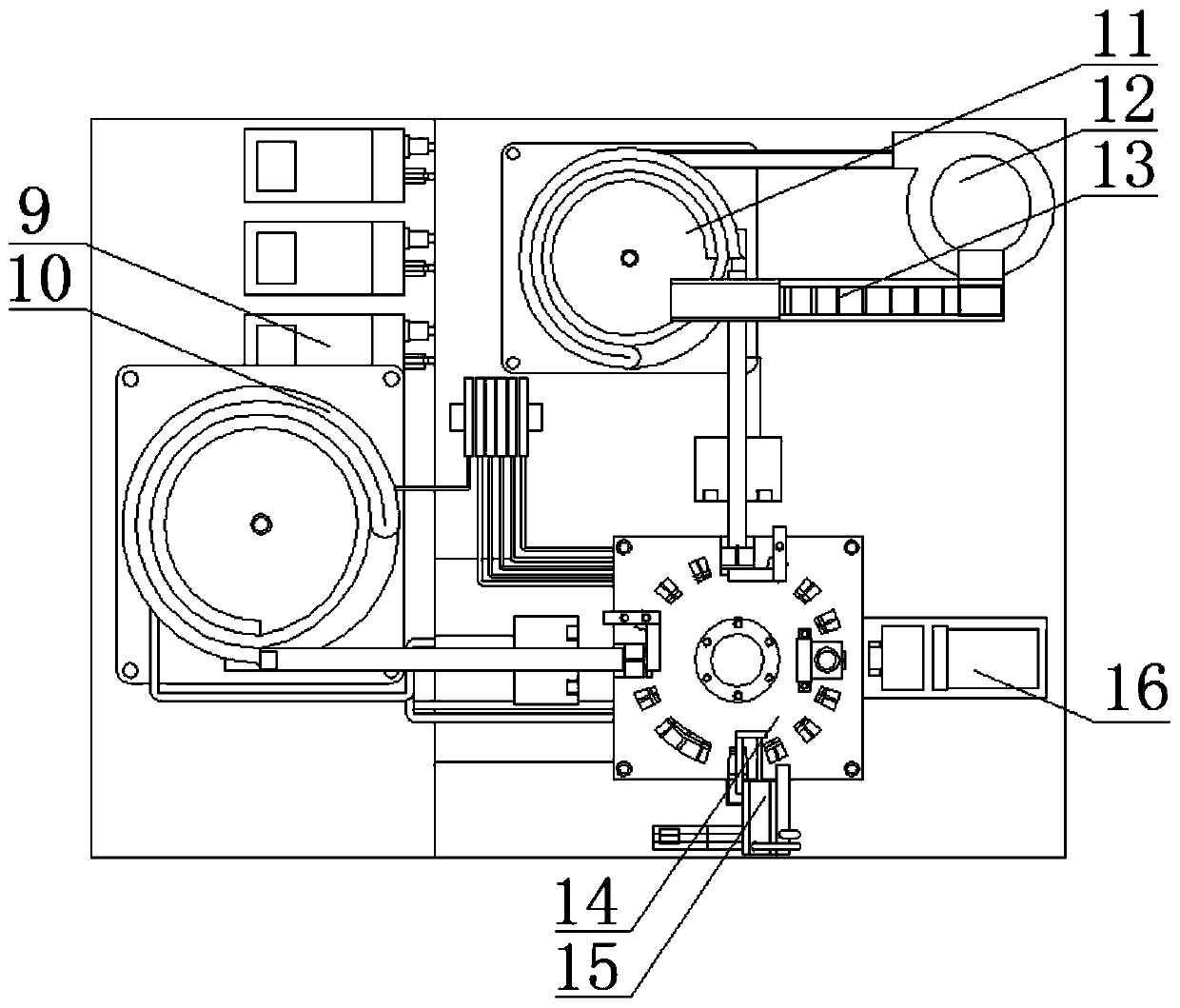

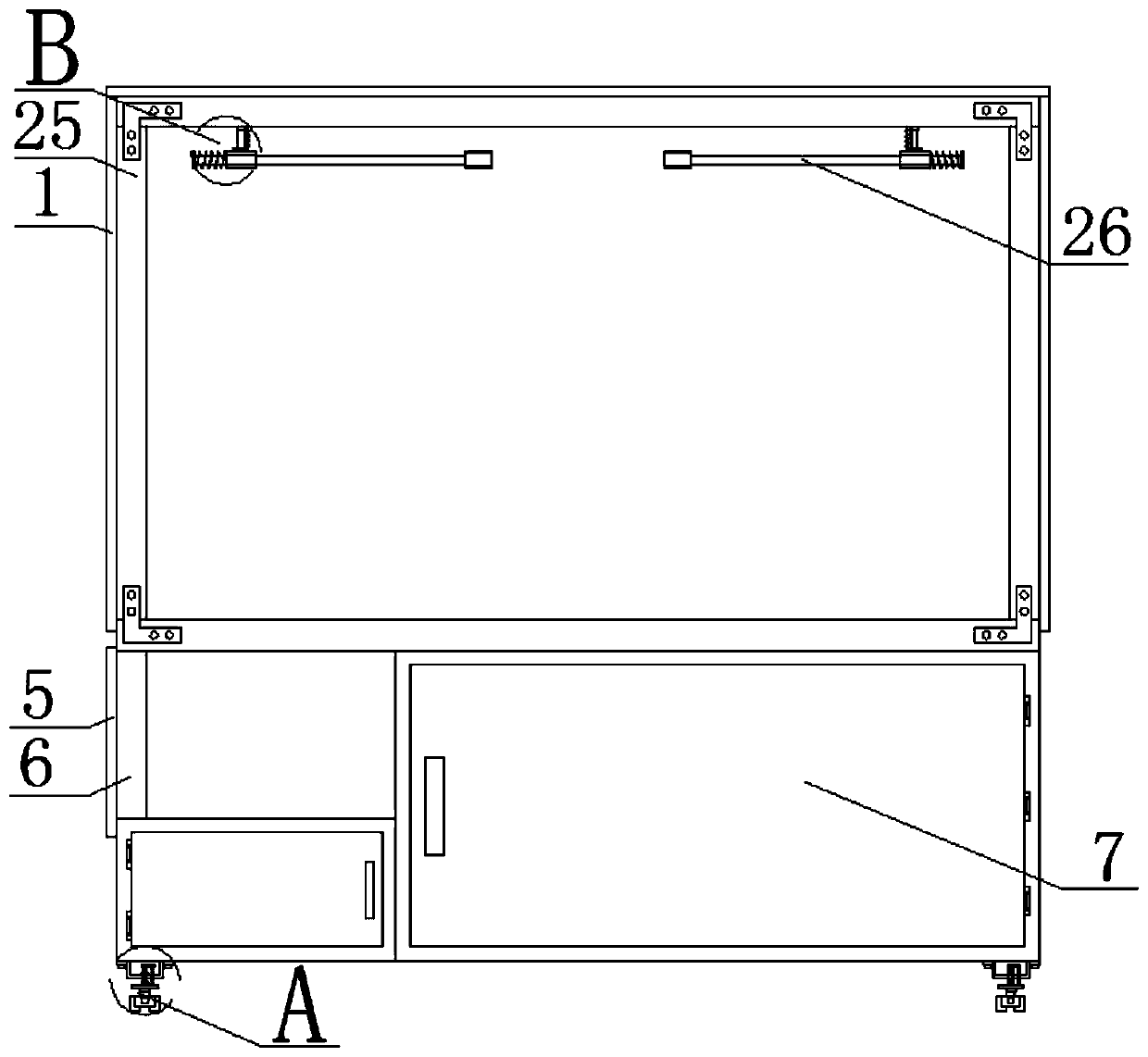

[0034] refer to figure 1 , 2 , 3, 7, 8, 9, 10, a kind of black rice spring automatic assembly equipment, including installation cabinet 7, is provided with electrical box equipment in the installation cabinet 7, thereby is convenient to connect with power supply, and then can supply energy for automation component, installs Two support columns 6 are fixed on one side of the upper end of the cabinet 7, and the two support columns 6 correspond to the other side of the upper end of the installation cabinet 7, and the two support columns 6 and the other side of the upper end of the installation cabinet 7 are jointly fixed with a protective frame 25. The protective frame 25 and the two support columns 6 can cover the automation components, thereby effectively isolating them from the outside world and preventing the outside world from affecting the quality of work.

[0035] In the present invention, an HM vibrating plate device 10 and three vibrating plate speed regulating devices ...

Embodiment 2

[0042] refer to figure 1 , 2 , 3, 4, 6, 7, 8, 9, 10, a black rice spring automatic assembly equipment, including an installation cabinet 7, the installation cabinet 7 is provided with electric box equipment, so as to facilitate connection with the power supply, and then can be used for automation components For energy supply, two support columns 6 are fixed on one side of the upper end of the installation cabinet 7, and the two support columns 6 correspond to the other side of the upper end of the installation cabinet 7, and the two support columns 6 and the other side of the upper end of the installation cabinet 7 share a common A protective frame 25 is fixed, and the protective frame 25 and two supporting columns 6 can cover the automation components, thereby effectively isolating them from the outside world and preventing the outside world from affecting the quality of work.

[0043] In the present invention, an HM vibrating plate device 10 and three vibrating plate speed ...

Embodiment 3

[0053] refer to figure 1 , 2 , 3, 7, 8, 9, 10, a kind of black rice spring automatic assembly equipment, including installation cabinet 7, is provided with electrical box equipment in the installation cabinet 7, thereby is convenient to connect with power supply, and then can supply energy for automation component, installs Two support columns 6 are fixed on one side of the upper end of the cabinet 7, and the two support columns 6 correspond to the other side of the upper end of the installation cabinet 7, and the two support columns 6 and the other side of the upper end of the installation cabinet 7 are jointly fixed with a protective frame 25. The protective frame 25 and the two support columns 6 can cover the automation components, thereby effectively isolating them from the outside world and preventing the outside world from affecting the quality of work.

[0054] In the present invention, an HM vibrating plate device 10 and three vibrating plate speed regulating devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com