A kind of manufacturing method and guide plate of digital porcelain powder layered plastic stacking guide plate

A production method and porcelain powder technology, applied in the field of medical equipment, can solve the problems of great influence on denture production and unstable production results, and achieve the effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

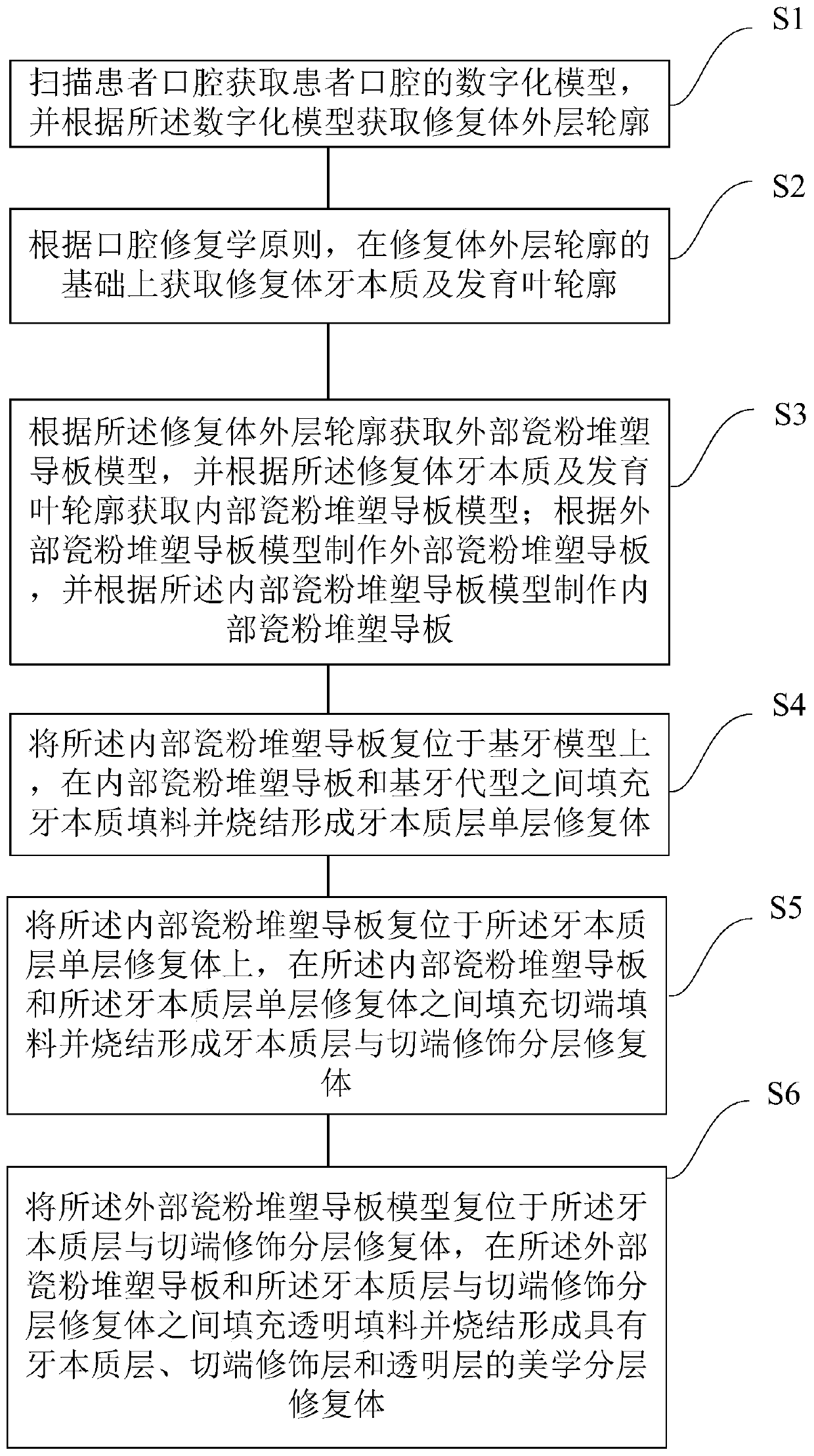

[0045] Such as figure 1 As shown, a method for making a digital porcelain powder layered plastic guide plate of the present invention comprises the following steps:

[0046] S1: Scan the patient's mouth to obtain a digital model of the patient's mouth, and obtain the contour of the outer layer of the restoration according to the digital model;

[0047] S2: According to the principles of prosthodontics, the dentin and developmental lobe contours of the restoration are obtained on the basis of the contour of the outer layer of the restoration;

[0048] S3: Obtain the external ceramic powder-plastic guide plate model according to the outer contour of the restoration, and obtain the internal ceramic powder-plastic guide plate model according to the contour of the restoration dentin and the developing leaf; make the external porcelain powder-plastic guide plate model according to the external porcelain powder-plastic guide plate model Powder-pile plastic guide plate, and make inte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap