Mold special for post injection molding sandwich compound insulation building blocks

A composite thermal insulation and post-injection technology, applied in household appliances, other household appliances, applications, etc., can solve the problems of low strength, increased cost, and long cooling and cooling time of polystyrene insulation boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

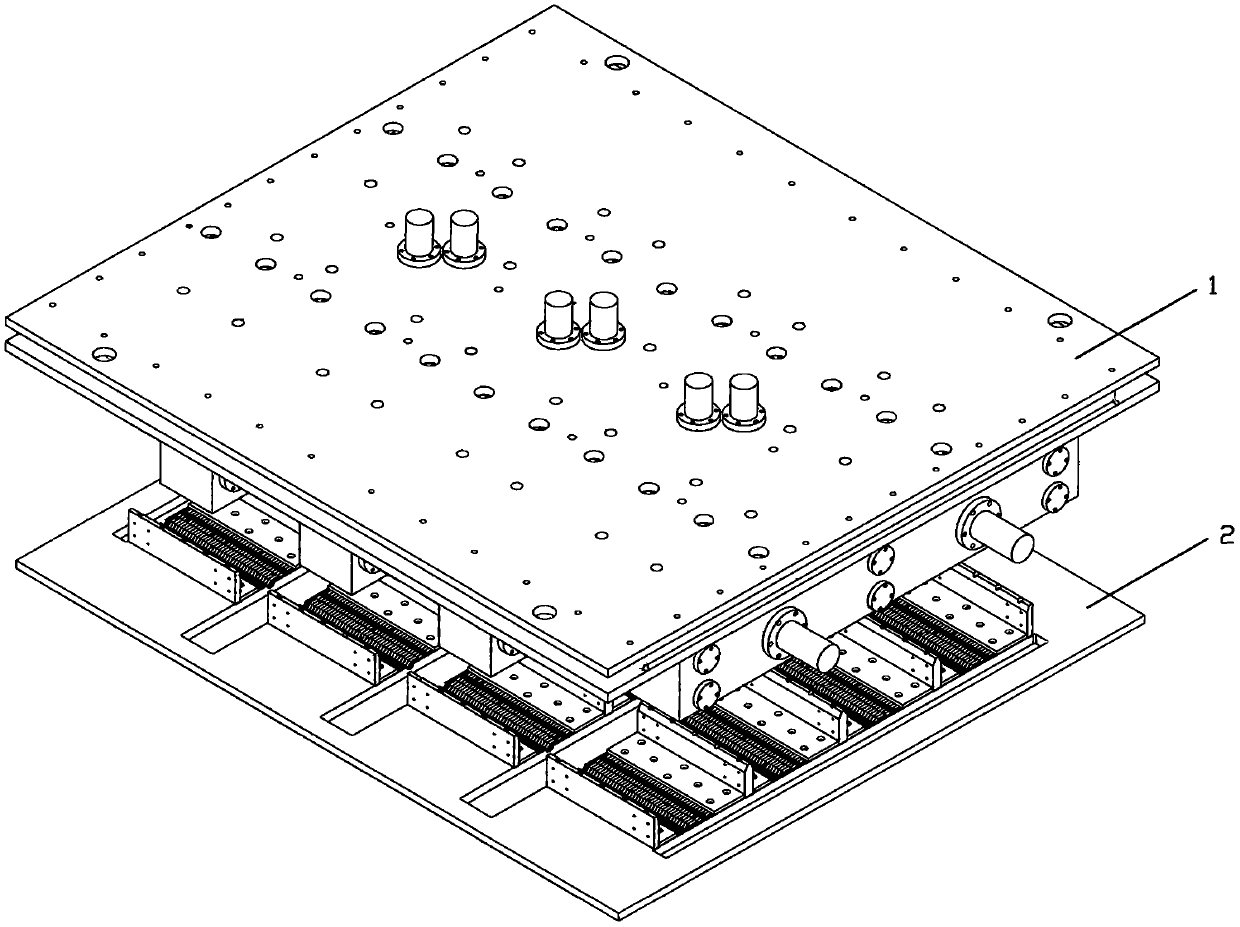

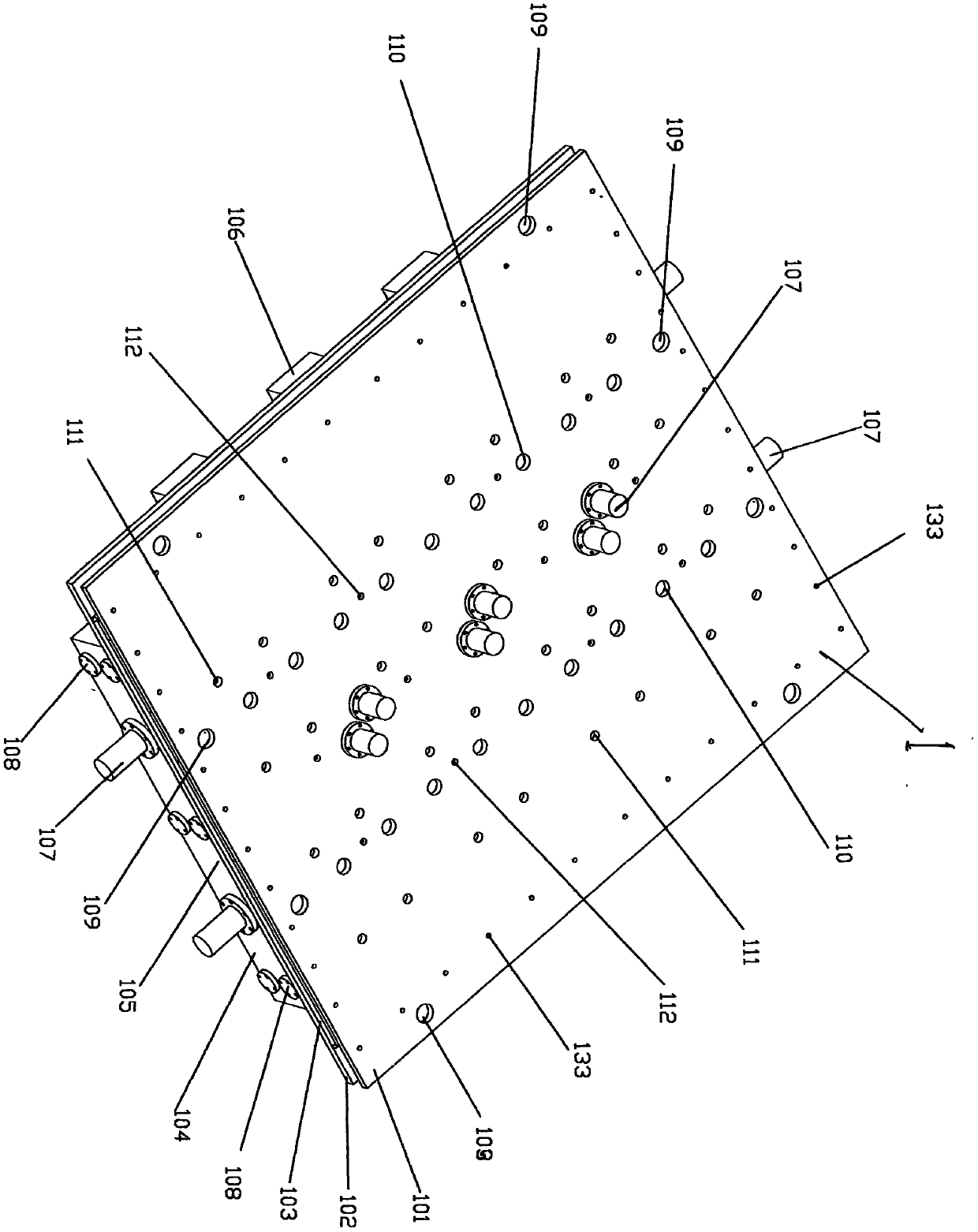

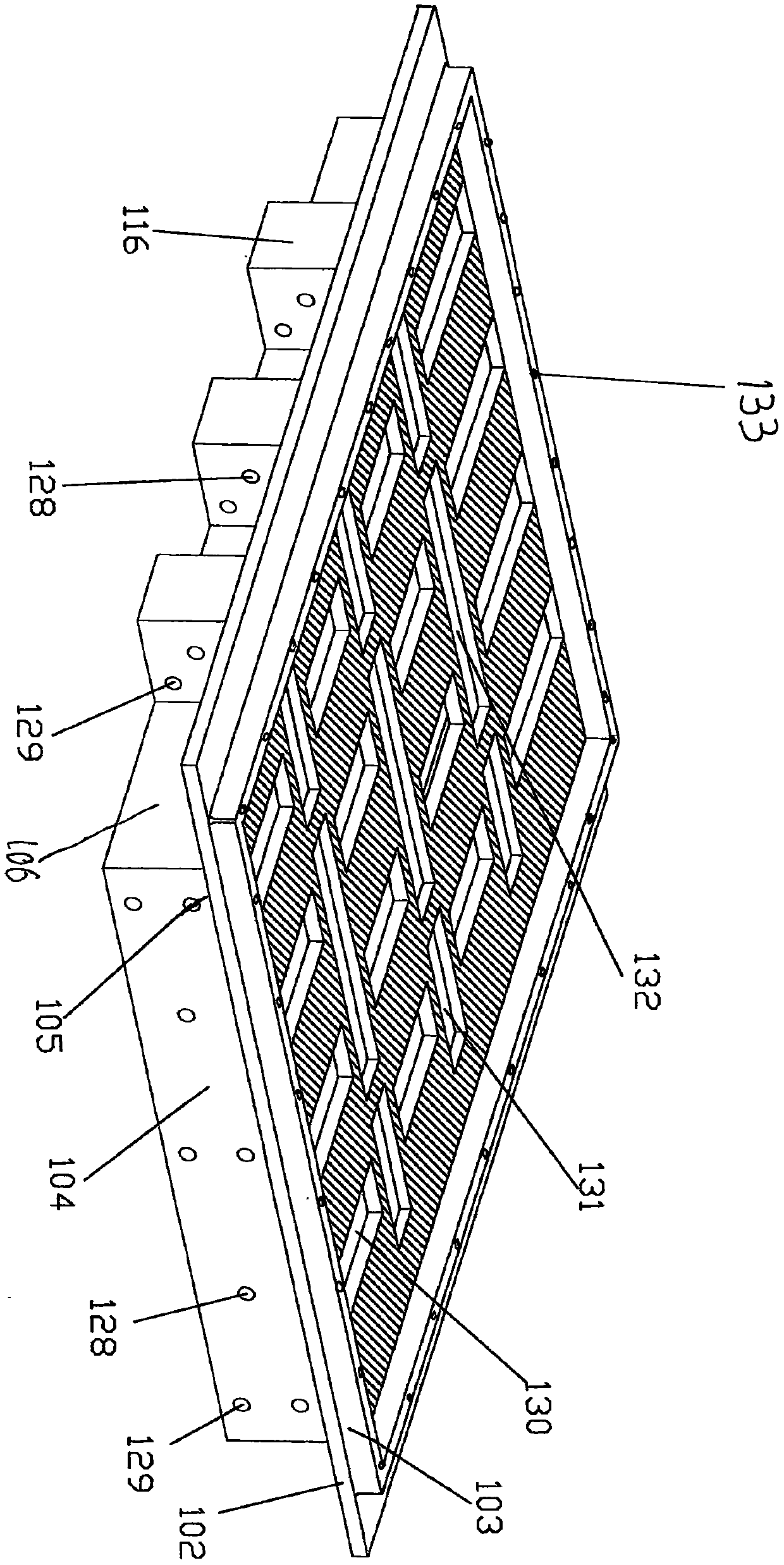

[0079] The present invention is achieved like this, below in conjunction with appendix Figure 1 to Figure 17 For further explanation: a special mold for post-injection sandwich composite thermal insulation blocks, including an upper mold 1 and a lower mold 2; , mold frame 104, several oil cylinders 107, several intermediate clamping plates 113, two end clamping plates 114, several guide shafts 115, several guide shaft flanges 108, several top steam / cooling water passing nets Plate 117, several side vertical steam / cooling water pass through mesh plate 121, several large heat-resistant rubber backing plates 118, several small heat-resistant rubber backing plates 119, and several top partitions 120; the lower mold 2 Consists of the lower template 201, several lower mold inner partitions 202, several lower mold outer partitions 203, several lower mold bottom steam / cooling water passing through the mesh plate 206, several large heat-resistant rubber backing plates 118, several A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com