Tire structure

A technology of tires and hubs, which is applied to tire parts, non-pneumatic tires, transportation and packaging, etc. It can solve the problems of heavy weight, air leakage and puncture, poor shock resistance, etc., and achieve light weight, high structural strength, and easy to use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to specific embodiments and accompanying drawings.

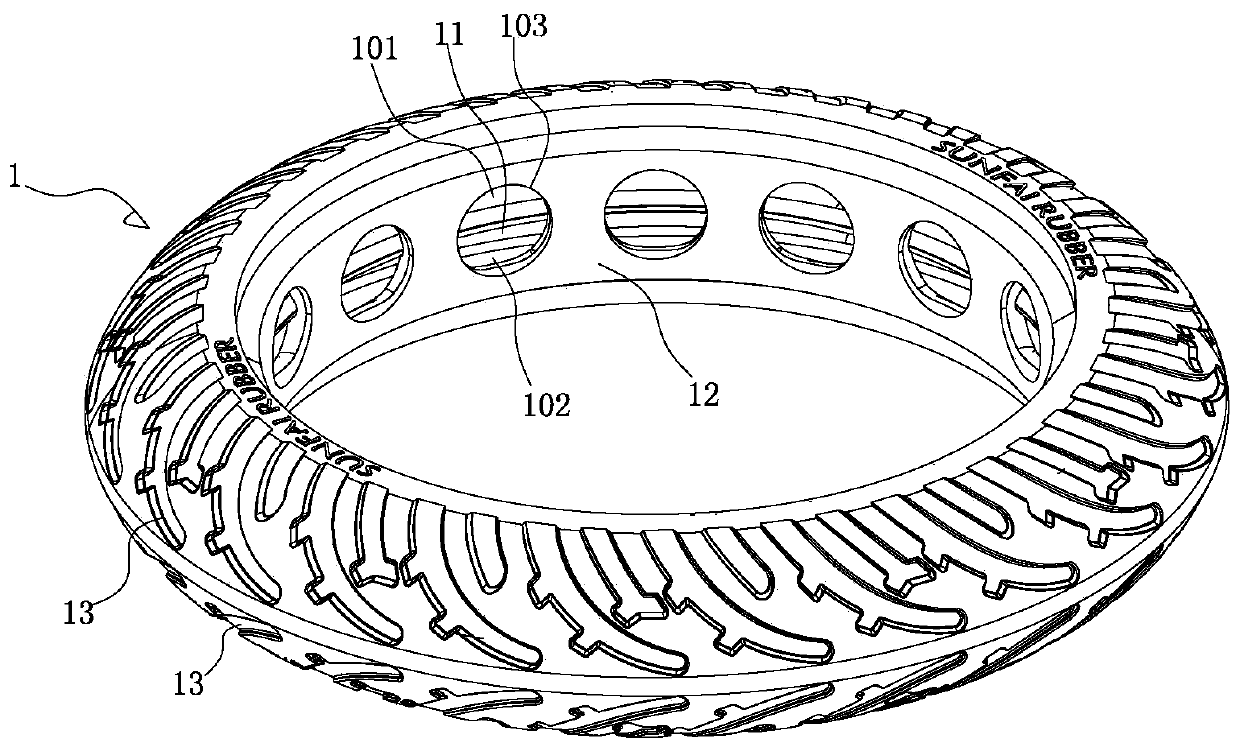

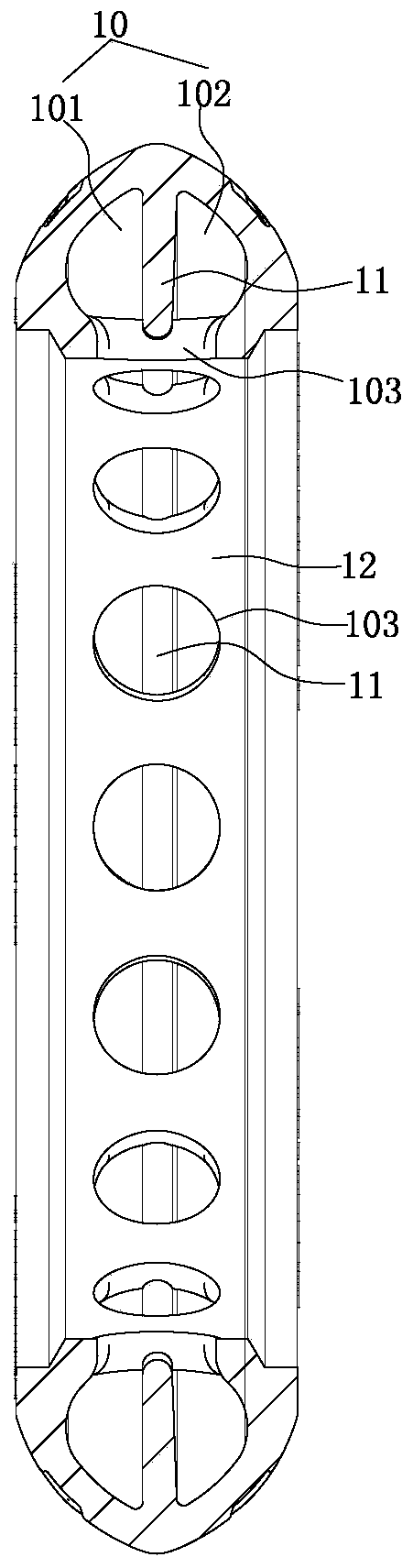

[0017] See figure 1 , 2 As shown, it is a tire structure, which includes an annular rubber carcass 1, a cavity 10 is formed inside the rubber carcass 1, and at least one partition support plate 11 is also formed inside the rubber carcass 1. The partition The support plate 11 divides the chamber 10 into at least two isolated first anti-vibration cavities 101 and second anti-vibration cavities 102; the inner wall of the rubber carcass 1 is provided with a number of through holes 103 inward, and the partition support plate 11 The end is exposed in the through hole 103, and the through hole 103 also communicates with the first anti-vibration cavity 101 and the second anti-vibration cavity 102 at the same time. After the rubber carcass 1 is installed on the wheel hub, the inside of the rubber carcass 1 The side surface is closely attached to the wheel h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com