A kind of preparation method of battery grade anhydrous iron phosphate

An anhydrous phosphoric acid, battery-level technology, applied in chemical instruments and methods, inorganic chemistry, phosphorus compounds, etc., can solve the problem of high iron source cost, affecting the performance of lithium iron phosphate and lithium iron phosphate batteries, high impurity content in iron phosphate, etc. problems, to achieve the effect of improving performance and eliminating differences in microscopic components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

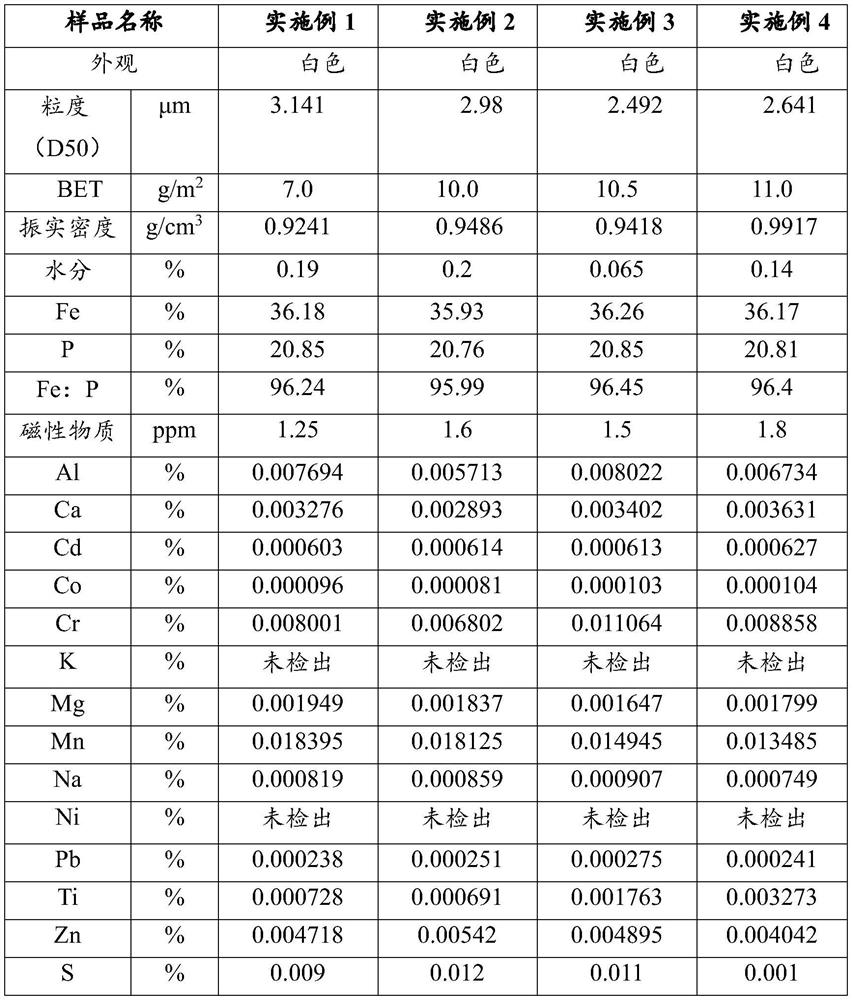

Embodiment 1

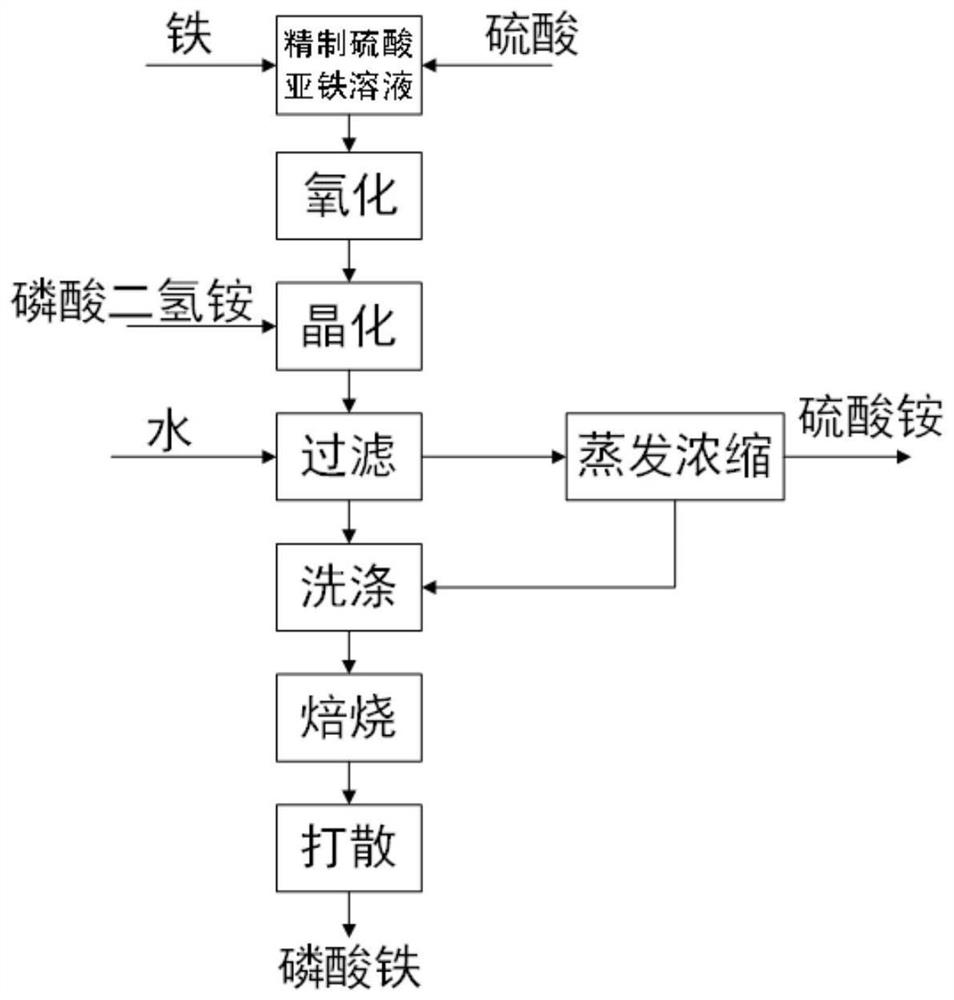

[0032] The method of the present embodiment was prepared battery grade anhydrous iron phosphate embodiment, see the flow chart figure 1 , The cold rolled iron automobile scrap iron source, and a concentration of 20% dilute sulfuric acid solution, the reaction under stirring for 3 hours to generate ferrous sulfate solution, ferrous sulfate solution was added to the impurity agent impurity, sediment filter, and the resulting filtrate is purified ferrous sulfate solution;

[0033] Purified ferrous sulfate solution with phosphoric acid - mixed urea solution adjusted to pH 2.0, followed by addition of impurity flocculant, the flocculant in an amount of 0.05% by mass of ferrous sulfate solution, a mixed coagulant flocculant, particularly polymerization sulfate EDTA and iron weight ratio 2: 1 mixture of flocculant is added, stirring rate 100r / min, the stirring time 5min, then the residue was removed by filtration, then purified to give a green solution of ferrous sulfate;

[0034] Puri...

Embodiment 2

[0041] The preparation method of the battery-level anhydrous phosphate of the present embodiment has a ferrous sulfate to produce titanium white powder by sulfuric acid. Specifically, Titanium iron ore is prepared at the end of sulfuric acid (SO 4 ) 2 Tioso 4 Generate FESO at the same time 4 And Fe 2 (SO 4 ) 3 , Acid solution to the generated Tioso 4 FESO 4 The mixture is removed, and the dissolved residual residue is removed by leaching and settling. The solution is added to the elbow after removing impurities, and the trivalent iron ions in the solution are present in the form of a divalent iron ion. Tioso 4 TI 2 (SO 4 ) 3 The form exists. Titanium solution treated with purification, concentrate, cooled by vacuum, so that ferrous sulfate is FESO 4 · 7h 2 O form is crystallized, centrifuged, that is, the raw material of the present embodiment.

[0042] The sulfate is dissolved in the ferrous acid method for the production of titanium white powder by the ferrous acid method. After...

Embodiment 3

[0049] The preparation method of the battery-level anhydrous phosphate in this example is based on the iron source of the automobile cold rolled iron plate, and the dilute sulfuric acid solution having a concentration is 20%, and the ferrous sulfate is formed under stirring. Solution, the ferrous sulfate solution is added to the dispense agent, and the obtained filtrate is a ferrous sulfate solution after purification.

[0050] The purified ferrous sulfate solution is mixed with phosphoric acid-urea to mix the pH to 2.0, then the flocculant is used in addition to 0.05%, the amount of ferrous sulfate is 0.05%, the flocculant is a mixed flocculant, specifically No. 3 After the flocculant and EDTA were added to a flocculant, the stirring rate was 100 r / min, stirred for 5 min, and then the residue was filtered, and a green sulfate refined solution was obtained;

[0051] Sulfate refined solution to the H 2 O 2 The solution and hydrogen peroxide is more than 10% higher than the calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com