Deformed steel bar and prestressed tendon connector and construction method for connection using same

A technology of prestressed tendons and construction methods, applied in the direction of basic structure engineering, structural elements, building components, etc., can solve the problems of difficult installation, inconvenient operation, limited construction space, etc., achieve high installation and construction efficiency, and improve anchorage reliability The effect of reducing the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] A threaded steel rod and prestressed tendon connector:

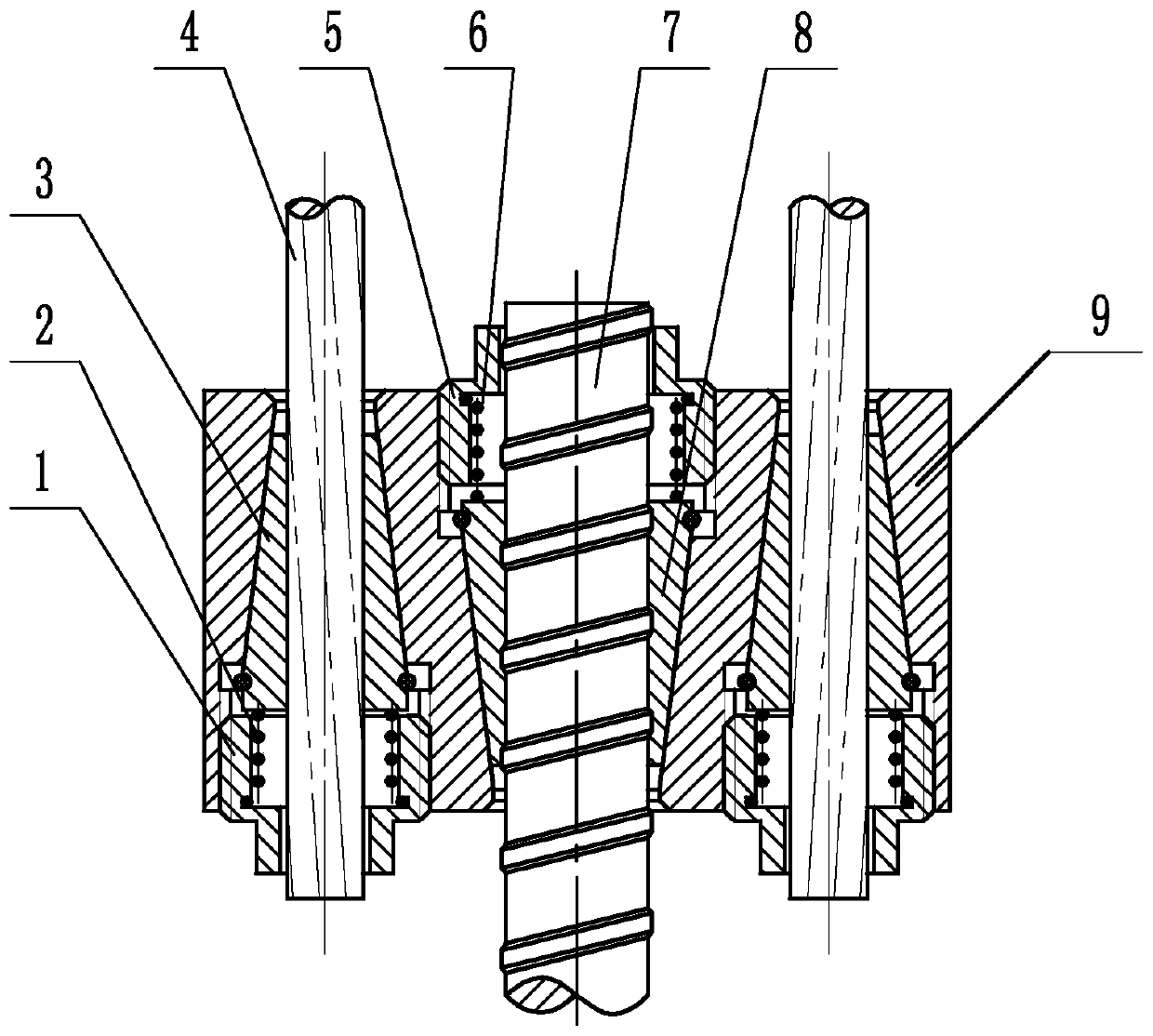

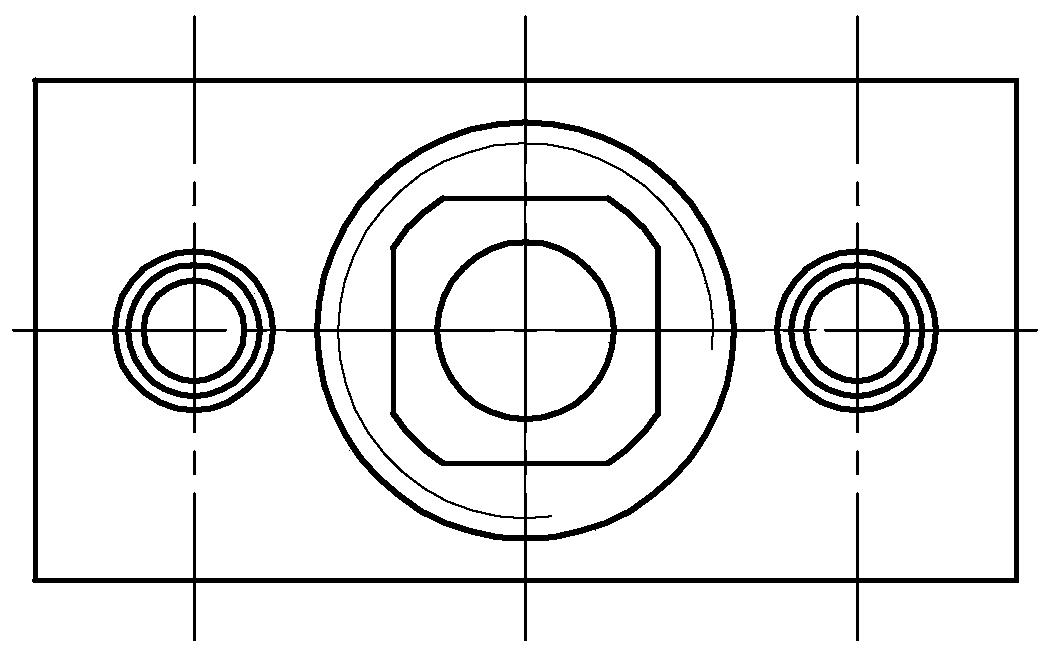

[0084] Such as figure 1 , figure 2 As shown, the threaded steel rod and prestressed tendon connector includes connecting anchor plate 9, clip I3, clip II8, hollow bolt I1, hollow bolt II5, columnar elastic body I2 and cylindrical elastic body II6;

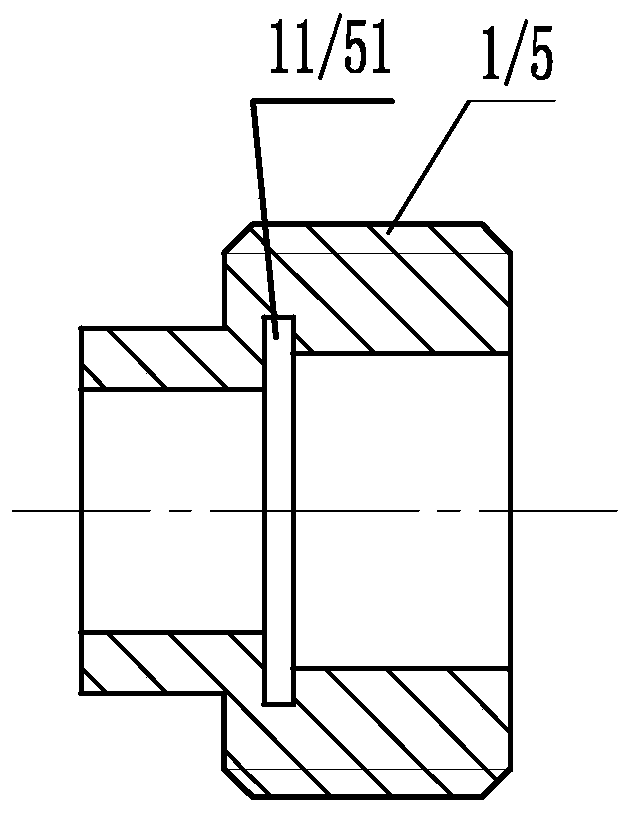

[0085] The connecting anchor plate 9 is used to realize the connection between the prestressed tendon and the threaded steel bar. The shape of the connecting anchor plate 9 is a columnar body, and the cross section of the columnar body is rectangular. The tapered hole I911 for installing the clip I3 and the internally threaded hole I912 for installing the hollow bolt I1 are connected through the tapered hole I911 and the internally threaded hole I912;

[0086] The other end face of the connecting anchor plate 9 is provided with a taper hole II921 for installing the clip II8 and an internally threaded hole II922 for installing the hollow bolt II5, and the taper hole...

Embodiment 2

[0106] A construction method for connection between threaded steel rods and prestressed tendons:

[0107] It is the construction method for the threaded steel rod and the prestressed tendon connector described in Embodiment 1 to be used for connecting the threaded steel rod and the prestressed tendon, including the following steps:

[0108] A. Preparation before construction:

[0109] A1. Prefabricated threaded steel rod and prestressed tendon connector components in the factory, including connecting anchor plate 9, clip Ⅰ3, clip Ⅱ8, hollow bolt Ⅰ1, hollow bolt Ⅱ5, columnar elastic body Ⅰ2 and cylindrical elastic body Ⅱ6 (see figure 1 , figure 1 Among them, the columnar elastic body Ⅰ2 and the cylindrical elastic body Ⅱ6 are the compression spring Ⅰ2 and the compression spring Ⅱ6);

[0110] A2. Assembling threaded steel rods and prestressed tendon connectors:

[0111] A21. Install clip I3 and clip II8 into taper hole I911 and taper hole II921 connecting anchor plate 9 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com