Connecting structure of beam and column in glass curtain wall

A glass curtain wall and connection structure technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of high cost of aluminum corners, poor reliability of brackets, easy torsion of beams, etc., to reduce construction difficulty and solve easy torsion , the effect of convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

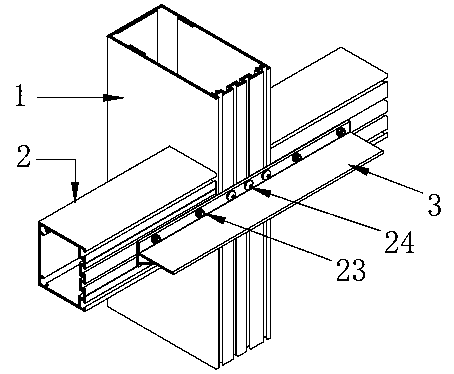

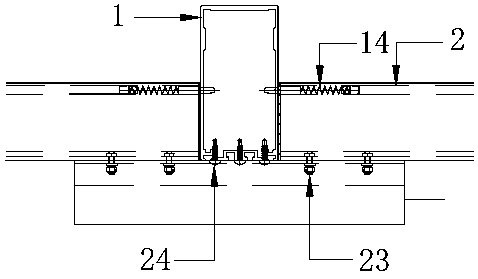

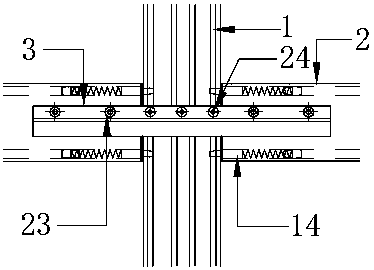

[0028] Such as Figure 1 to Figure 5 As shown, the frame of the connection structure between the beam and the column in the glass curtain wall of the present invention is composed of vertically overlapping columns 1 and beams 2, and the beams 2 on the left and right sides of the column 1 pass through the elastic pins 4 in the inner cavity and the external connectors. 3 is connected with column 1. The front ends of the column 1 and the beam 2 are flush, and the connecting piece 3 is arranged along the length direction of the beam 2 and connected with the beam 2 and the column 1 at the same time. Both the column 1 and the beam 2 are of square tube profile structure, and the structures of the front ends of the two are basically the same. The front end face of the column 1 includes a first rubber strip groove 4, a first section surface 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com