Quick-plug connector seat

A technology of plug joints and male plugs, applied in the direction of connection, conductive connection, contact parts, etc., can solve the problems of large return torque, inconvenient operation, cable knotting, etc., to adjust the clamping tightness, ensure clamping firm and convenient The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

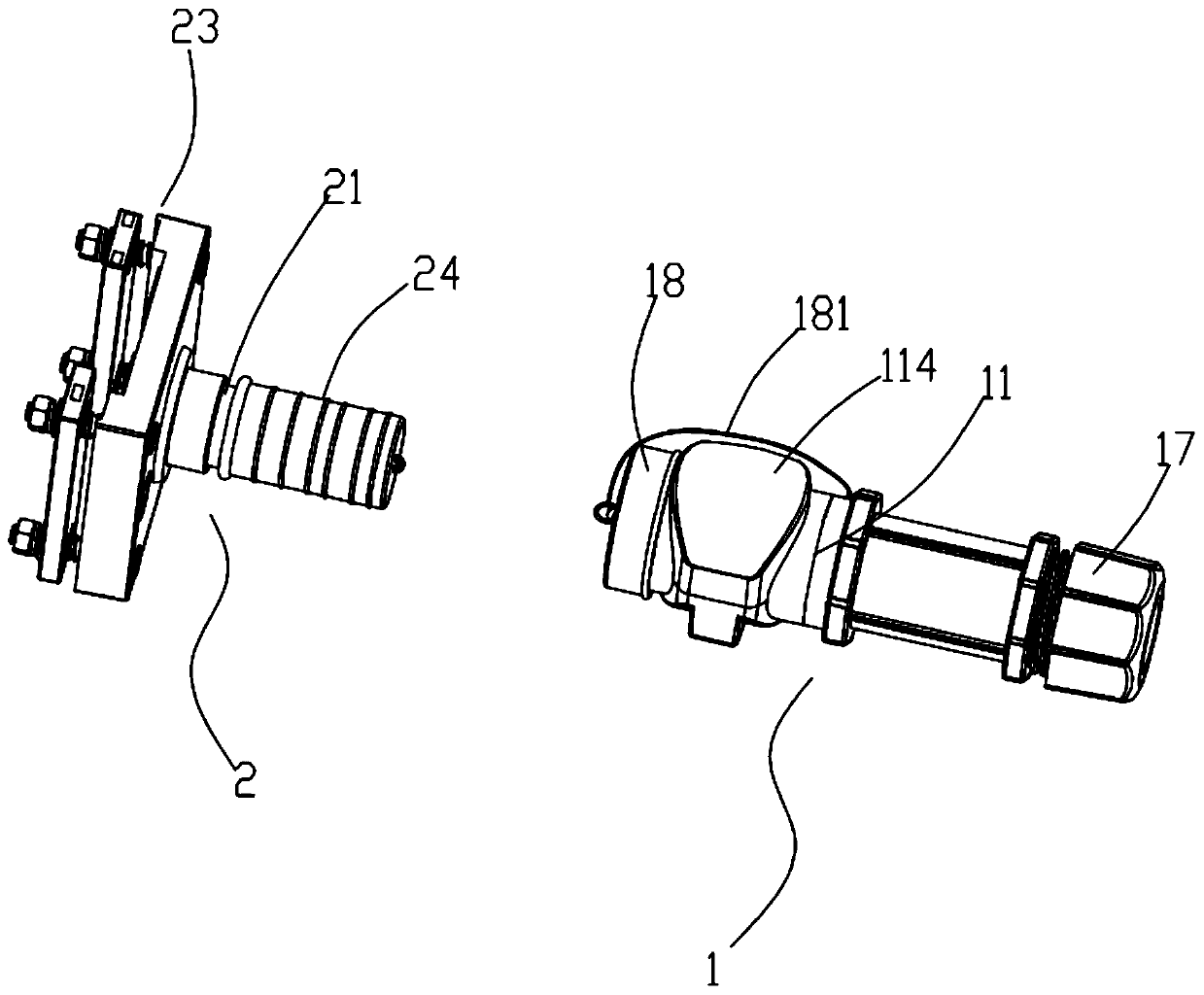

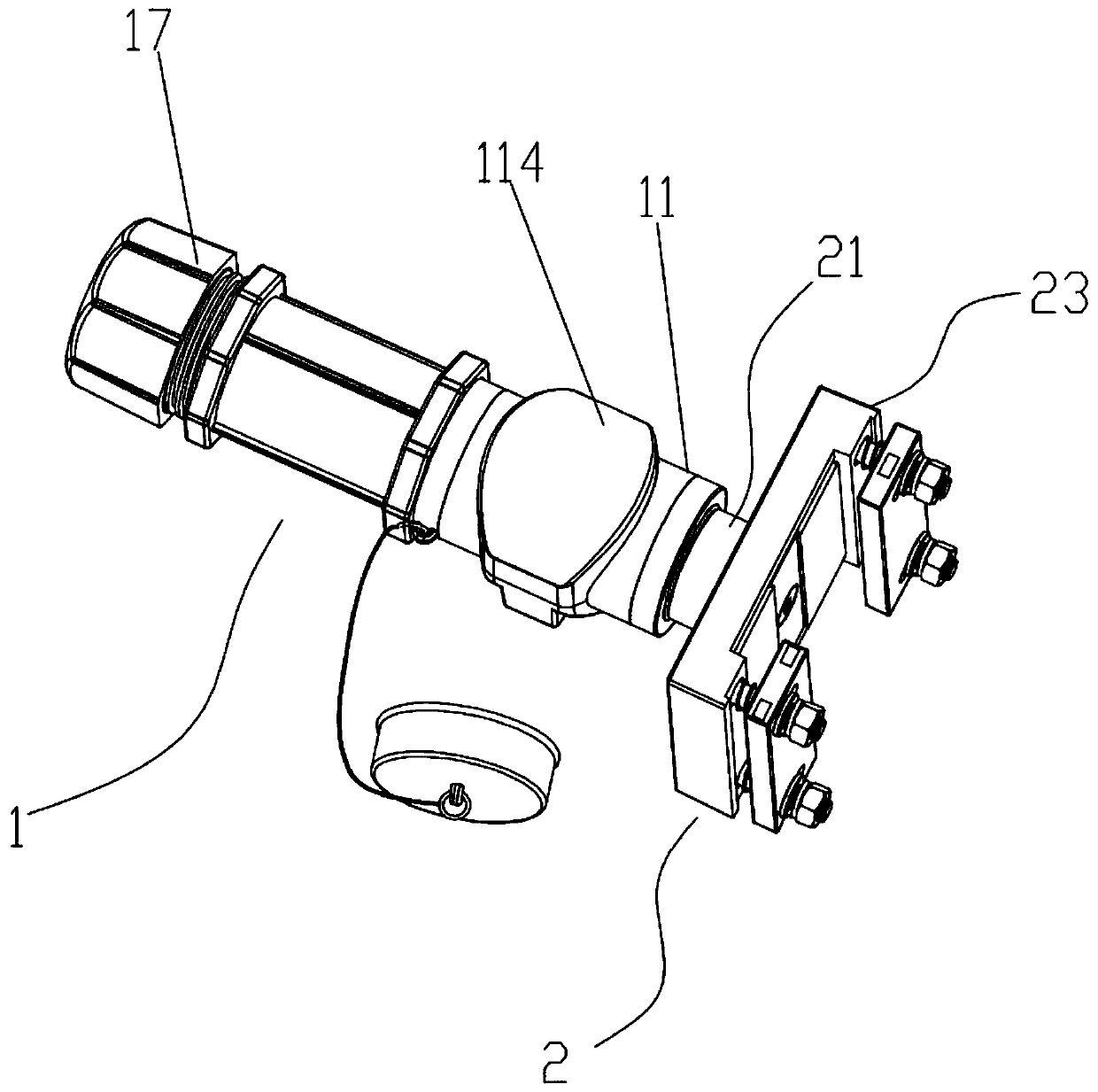

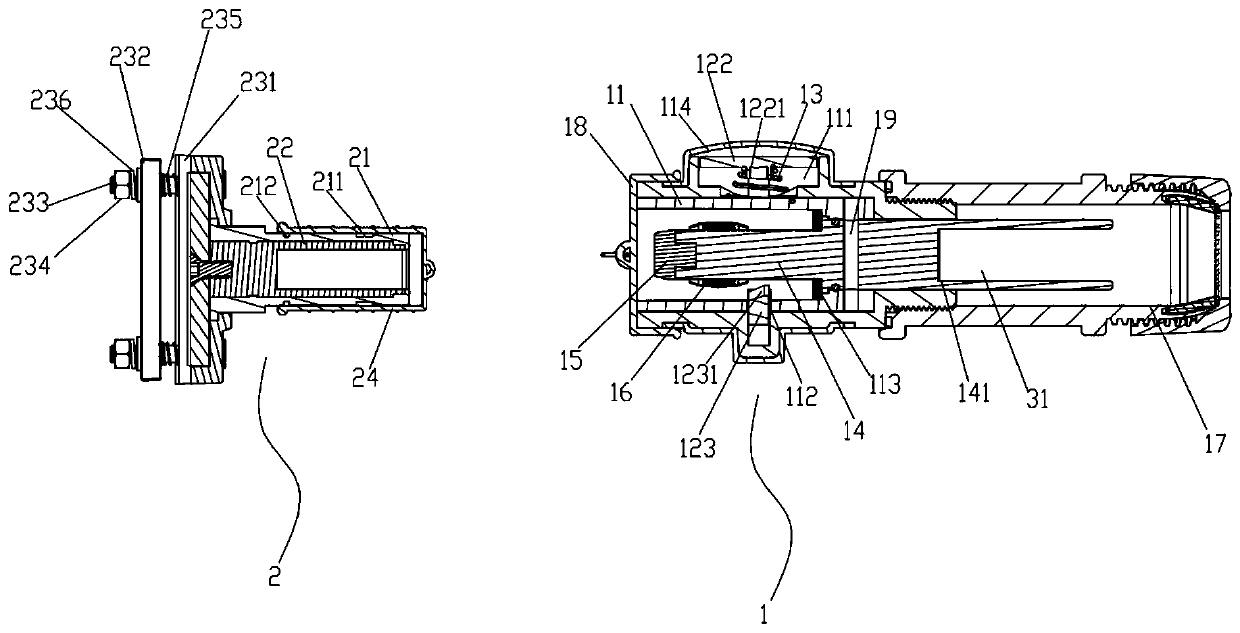

[0030] Such as Figure 1-5 As shown, the push-in connector seat includes a female plug 1 and a male plug 2. The female plug 1 includes an insulating sleeve 11, a conductive finger 14 and a locking key 12. The locking key 12 is a ring structure, including a ring The main body 121 and the pressing part 122 and the latch 123 arranged on opposite sides of the annular body 121, the outer wall of the insertion sleeve 11 is provided with an accommodating groove 111 for guiding the locking key 12, and the locking key 12 is sleeved on the insertion sleeve The barrel 11 is placed outside the housing groove 111, and a pre-tension spring 13 is provided between the pressing part 122 and the outer wall of the socket sleeve 11, and a pin hole 112 is provided on the socket sleeve 11 facing the pin 123. The elastic force of the pre-tension spring 13 enables the end of the plug pin 123 to be inserted into the inner cavity of the socket sleeve 11 through the pin hole 112. There is a wedge-shape...

Embodiment 2

[0040] On the basis of the technical solution of embodiment 1, the conductive positioning mechanism has been changed:

[0041] Such as Figure 6 As shown, the conductive positioning mechanism is a connection terminal 237, one end of the connection terminal 237 is fixedly connected to the conductive cylinder 22, and the other end is provided with a mounting hole 2371 for fixing and connecting the conductor through screws. Compared with the elastic clip seat 23, this structure has a simpler structure and is more convenient to use, although the scope of use is smaller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com