A cleaning device for the production of limestone powder

A cleaning device and limestone powder technology are applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., and can solve the problems of discharge to road surfaces or seepage wells, waste of water resources, and low utilization rate of water resources. , to achieve the effect of thorough cleaning, avoiding waste and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

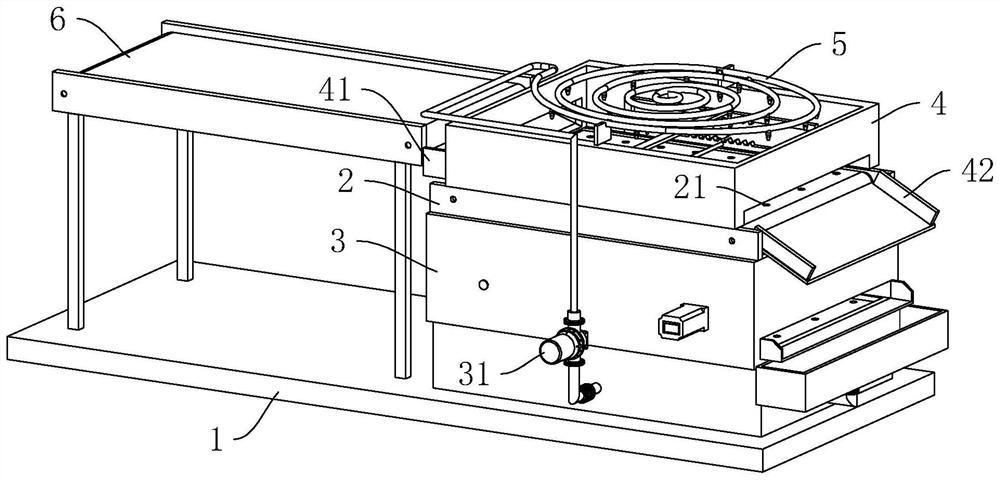

[0036] Such as figure 1 As shown, a cleaning device for the production of limestone powder includes a base 1 on which a conveyor belt 2 arranged along its length and a water collection tank 3 located below the conveyor belt 2 are arranged, and the conveyor belt 2 is evenly distributed with Some permeable holes 21.

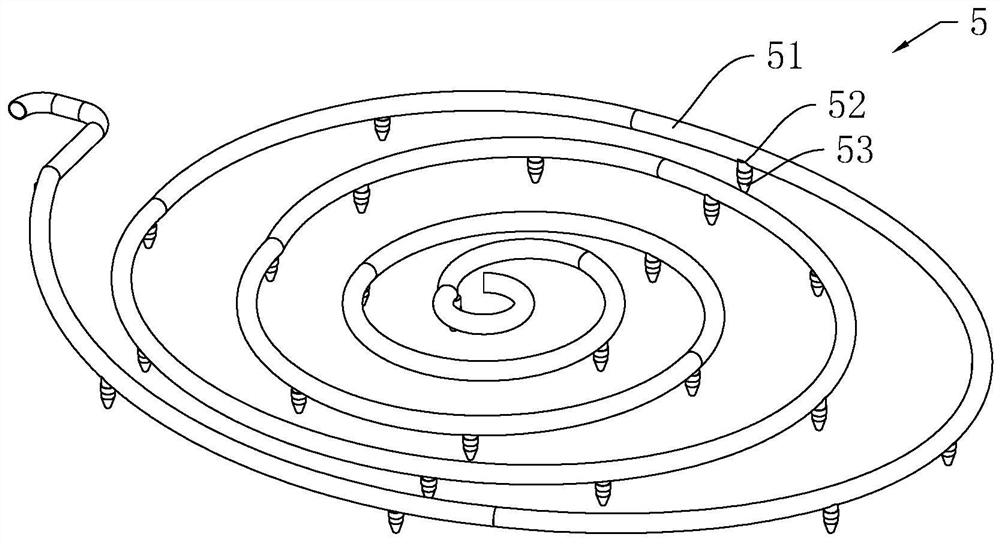

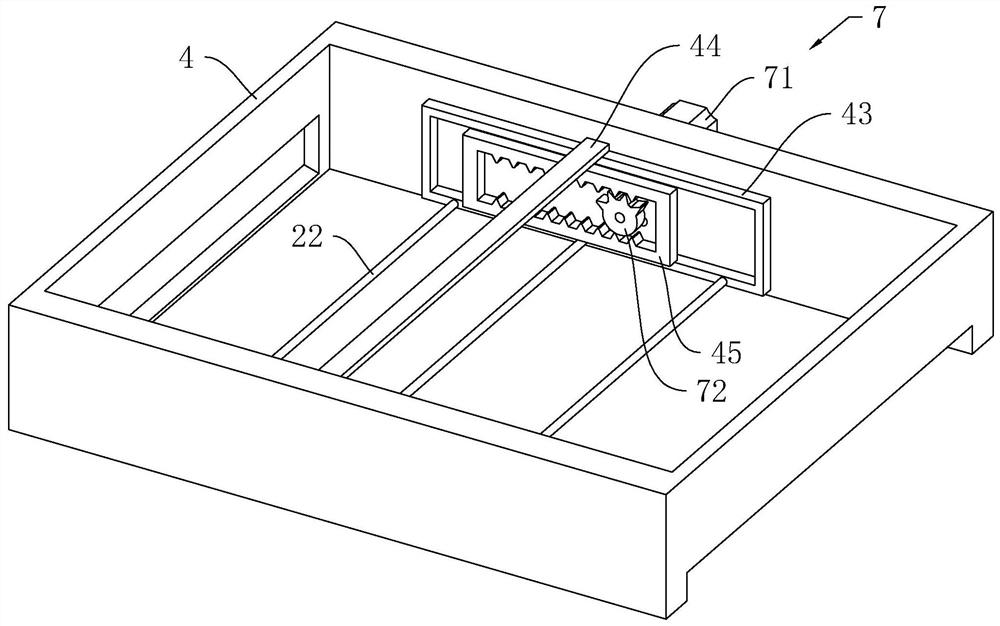

[0037] Such as figure 1 , figure 2As shown, the upper end surface of the conveyor belt 2 is provided with a protective cover 4 surrounding it, and the upper end of the protective cover 4 is provided with a spray mechanism 5 . The spraying mechanism 5 includes a coil pipe 51 coiled above the protective cover 4 , a plurality of water spray holes 52 are evenly distributed on the lower surface of the coil pipe 51 , and fan-shaped nozzles 53 are arranged in the water spray holes 52 .

[0038] Such as figure 1 As shown, the base 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com