Positioning mechanism of engraving and milling machine

A positioning mechanism, engraving and milling machine technology, used in multi-purpose machinery, forming/shaping machines, special forming/shaping machines, etc., can solve the problem of low positioning accuracy, improve positioning ability, ensure positioning ability, increase positioning range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

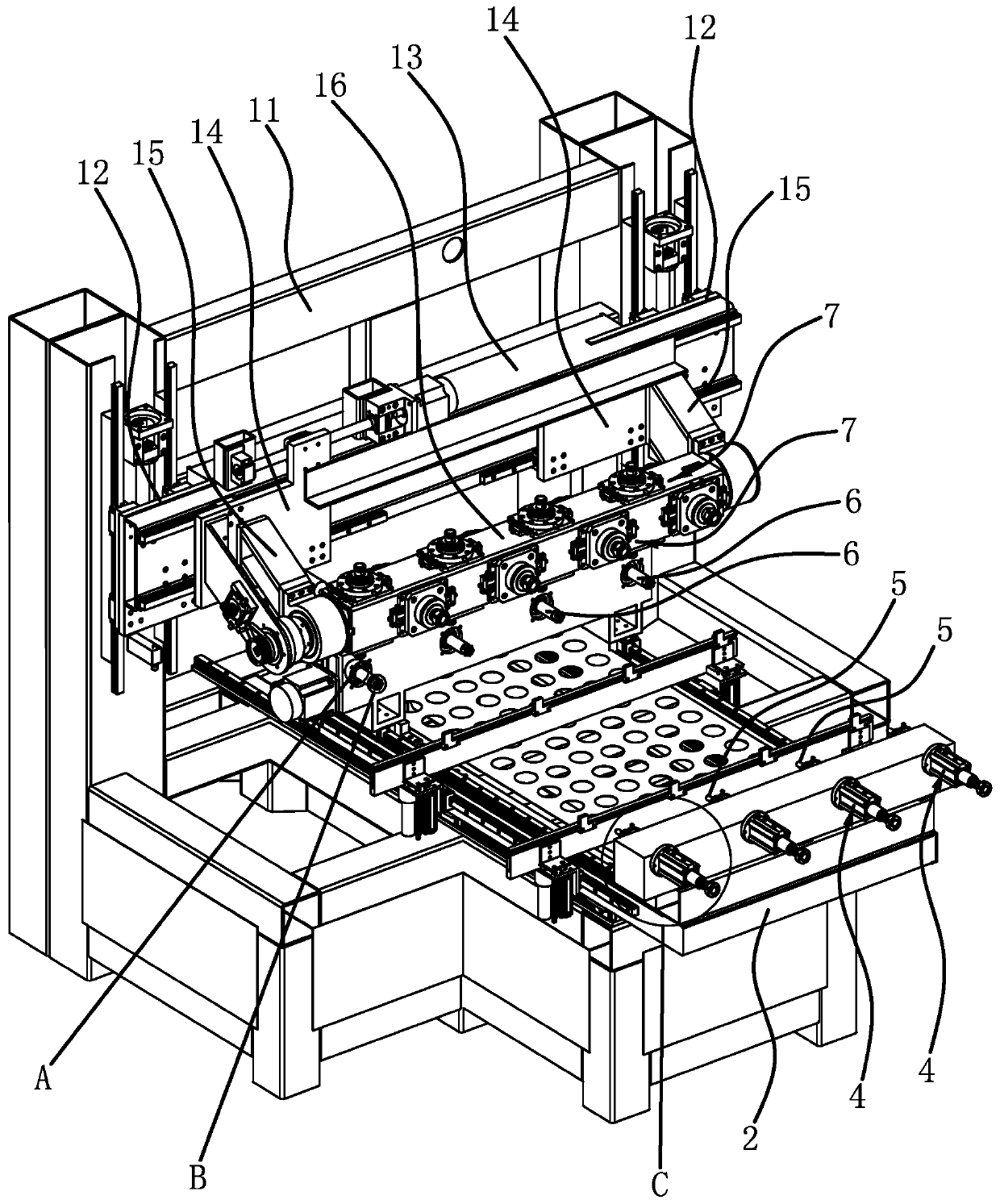

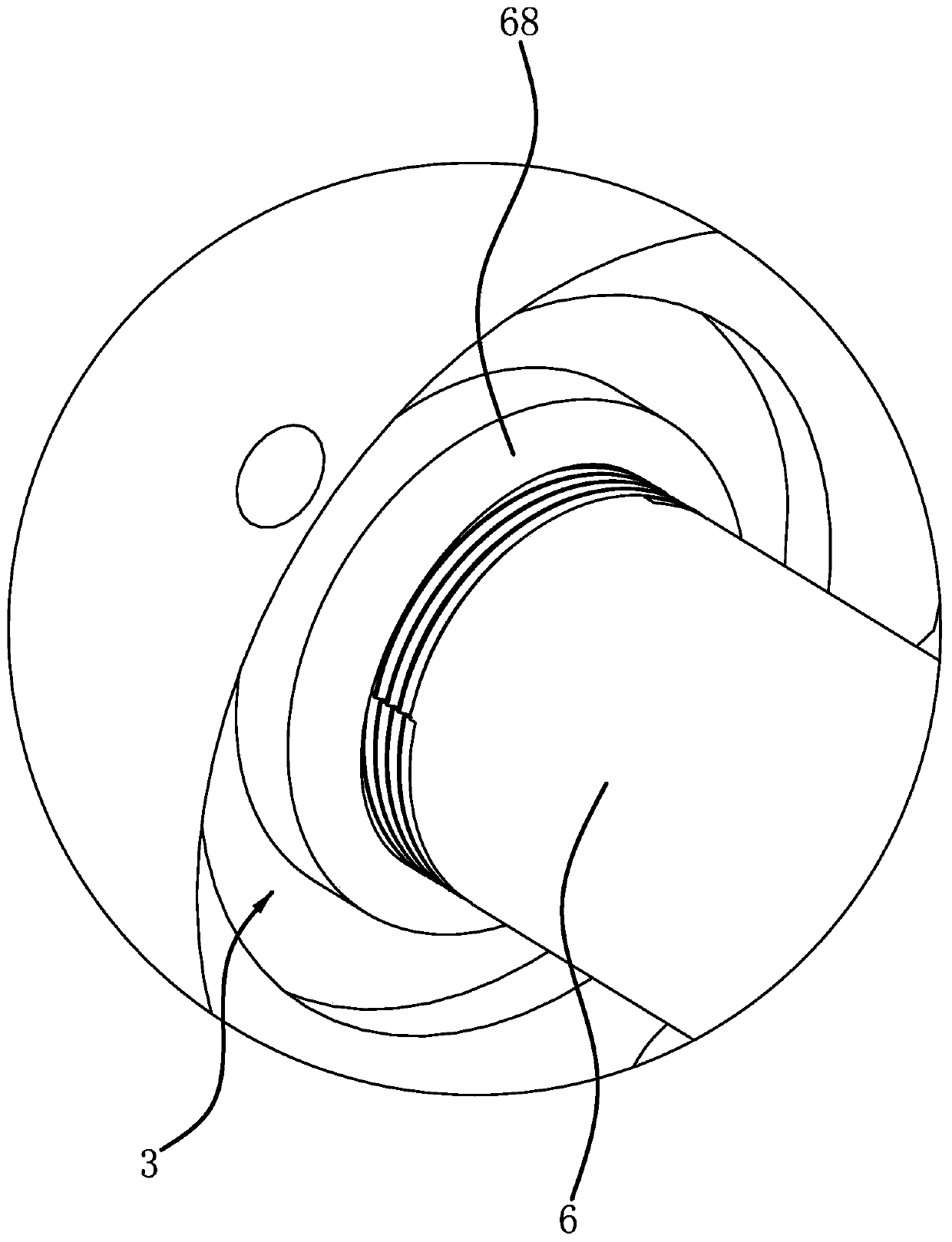

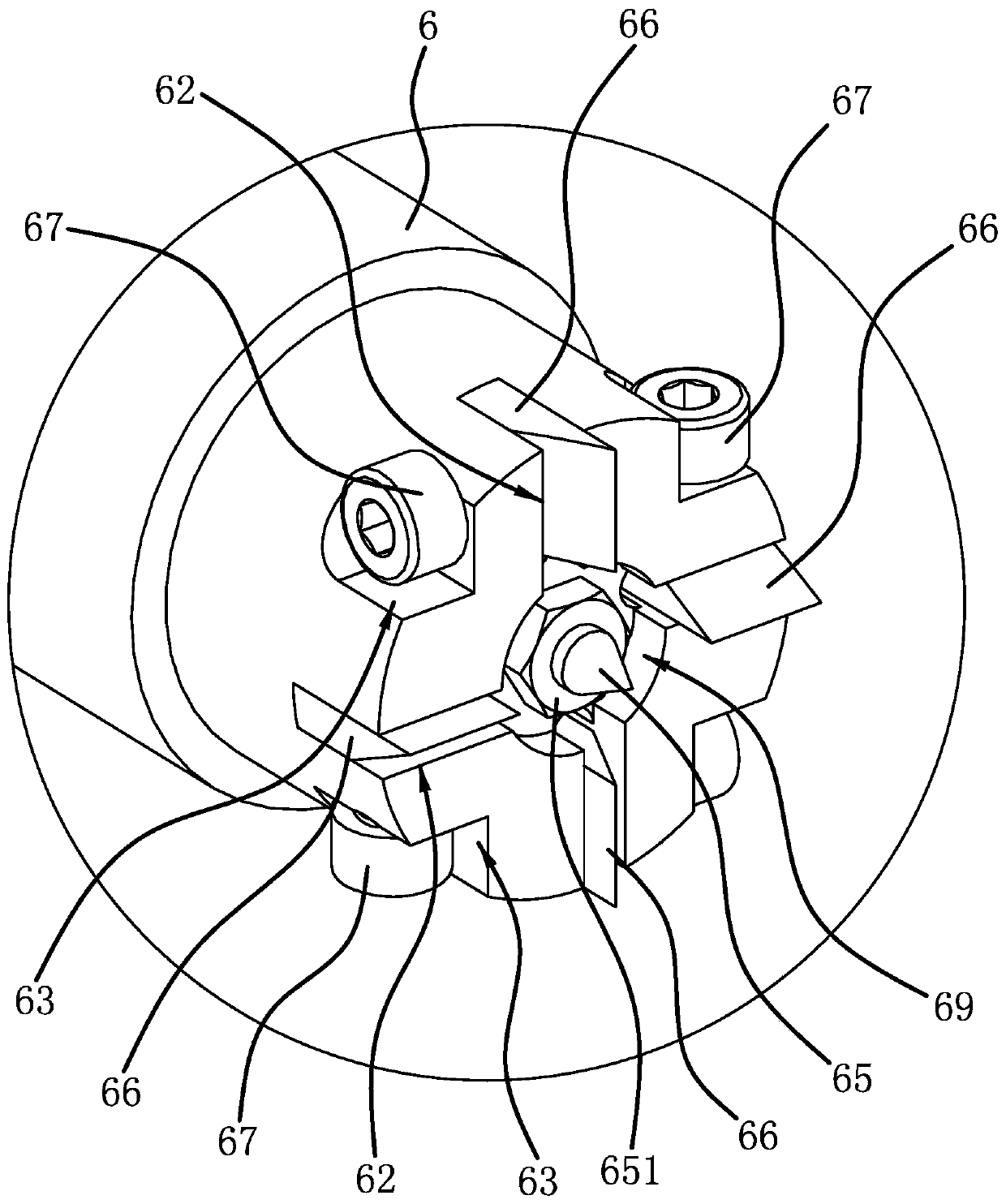

[0029] Such as figure 1 As shown, the positioning mechanism of the engraving and milling machine, the engraving and milling machine includes a frame 1, and the frame 1 is provided with a gantry 11, and the two columns of the gantry 11 are vertically slidably connected with a vertical carriage 12, and the two vertical carriages 12 A crossbeam 13 is fixed horizontally between them, on the crossbeam 13, a horizontal carriage 14 is slidably connected in the transverse direction, and two supports 15 are fixed on the transverse carriage 14, and a strip-shaped tool holder 16 is rotatably connected between the two supports 15 , the tool holder 16 is arranged horizontally, on the tool holder 16 there are multiple groups of processing components 7 along the horizontal direction, the processing components 7 are processing motors, cutter heads, milling heads, etc., and a processing platform is also slidingly connected longitudinally on the frame 1 2. The vertical carriage 12, the horizont...

Embodiment 2

[0033] The positioning mechanism of the engraving and milling machine is basically the same as that of the first embodiment, except that the positioning column 65 and the rotating shaft 6 are integrally structured to increase the structural strength and stability of the positioning column 65 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com