Improved vase type column concrete pouring and vibrating method

A technology of pouring, vibrating, and concrete, which is applied in construction, bridge parts, erection/assembly of bridges, etc. It can solve problems such as object strikes, staff heatstroke, and difficulties for staff to enter and exit the formwork, so as to achieve convenient and durable grip and good grip The effect of maintaining and improving work safety factor and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 of the present invention: an improved vase type column concrete pouring and vibrating method, comprising the following steps:

[0025] S1, according to the size of the column formwork, prepare several extended vibrating rods 1, so as to cover the vibrating range of the column;

[0026] S2, pouring concrete on the column formwork;

[0027] S3, the worker stands on the top of the pier and lowers the vibrating rod head 2 of the extended version of the vibrating rod 1 into the concrete at the bottom of the column to eliminate air bubbles and voids in the concrete;

[0028] S4, according to the concrete pouring speed, correspondingly raise the vibrator head 2;

[0029] S5, after the concrete is poured to a specific position, the pouring is ended;

[0030] S6, continue to vibrate according to the vibration requirement until the air voids in the concrete are eliminated.

Embodiment 2

[0031] Embodiment 2: An improved vase type column concrete pouring and vibrating method, comprising the following steps:

[0032] S1, according to the size of the column formwork, prepare several extended vibrating rods 1, so as to cover the vibrating range of the column;

[0033] S2, pouring concrete on the column formwork;

[0034] S3, the worker stands on the top of the pier and lowers the vibrating rod head 2 of the extended version of the vibrating rod 1 into the concrete at the bottom of the column to eliminate air bubbles and voids in the concrete;

[0035] S4, according to the concrete pouring speed, correspondingly raise the vibrator head 2;

[0036] S5, after the concrete is poured to a specific position, the pouring is ended;

[0037] S6, continue to vibrate according to the vibration requirement until the air voids in the concrete are eliminated.

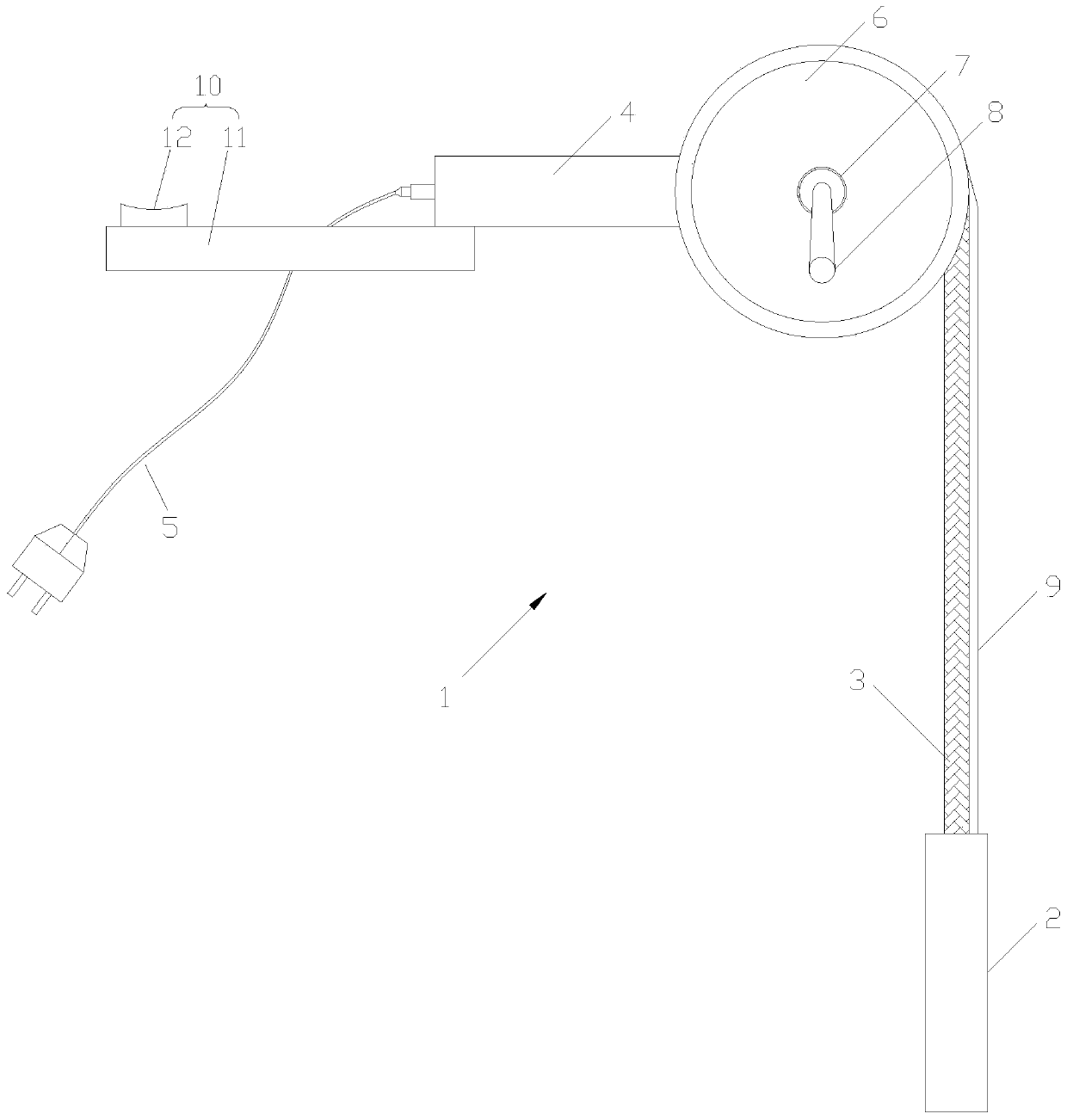

[0038] Such as figure 1 As shown, wherein, the extended version of the vibrator 1 includes a vibrator head 2, a ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com